Vehicle pneumatic-internal combustion hybrid power system based on comprehensive recovery and utilization of energy

A technology of hybrid power system and pneumatic engine, which is applied in the direction of internal combustion piston engine, engine components, engine operation, etc., can solve the problems that the total energy efficiency cannot be maximized, so as to improve fuel economy, power and economy , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

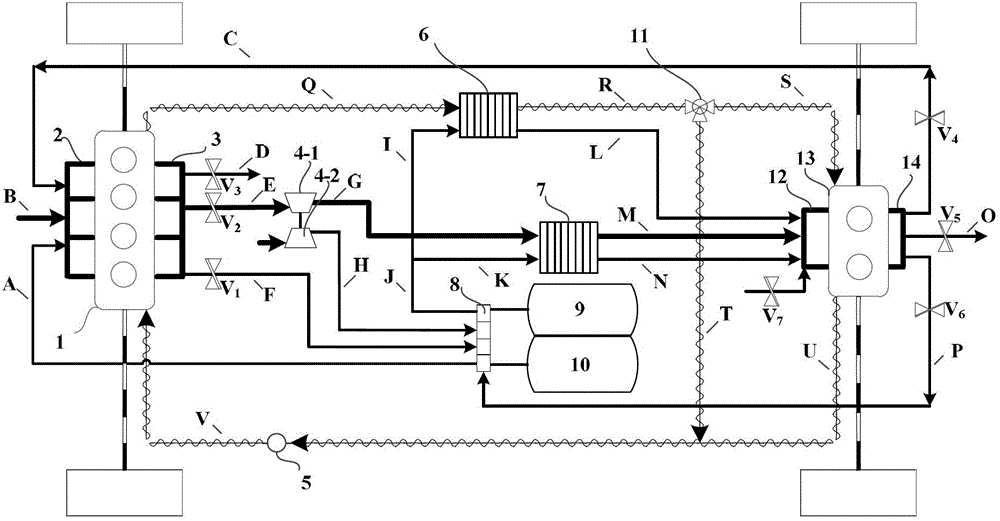

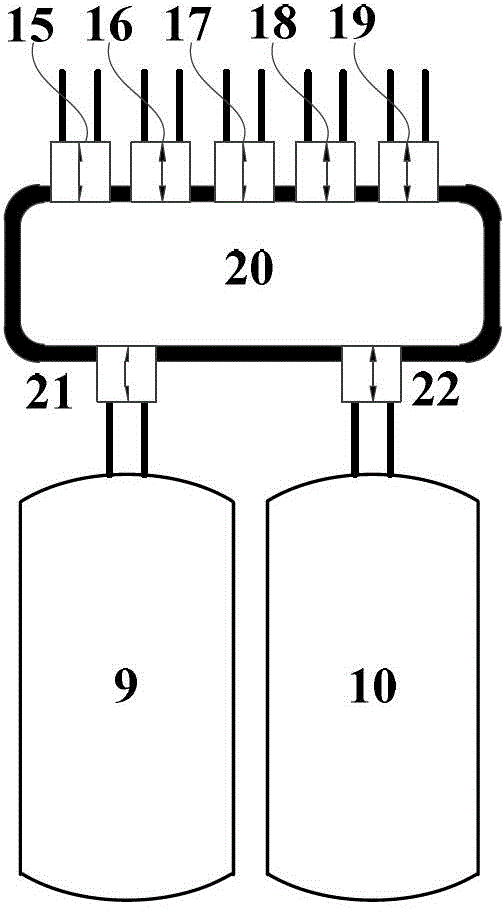

[0019] The system embodiment of the present invention includes a water-cooled internal combustion engine 1, an exhaust gas turbine-compressor unit, a water pump 5, a water-air heat exchanger 6, an air-air heat exchanger 7, a gas control valve group 8, a low-pressure gas storage tank 9, High-pressure gas storage tank 10, electronic thermostat 11, air motor 13, gas pipelines A, B, C, D, E, F, G, H, I, J, K, L, M, N, O, P , cooling water pipeline Q, R, S, T, U, V, two-way valve V 1 , V 2 , V 3 , V 4 , V 5 , V 6 , V 7 . The gas control valve group 8 includes solenoid valves 15 , 16 , 17 , 18 , 19 , 21 , 22 and a buffer chamber 20 . The outlet of the exhaust pipe of the internal combustion engine 1 is respectively connected with the compressed air energy storage system, the inlet of the exhaust gas turbine 4-1 and the atmosphere, and two-way valves V are respectively arranged on the pipelines. 1 , V 2 , V 3 ; The inlet of the compressor 4-2 is connected to the atmosphere,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com