Partial discharge work frequency synchronization signal sensing device

A partial discharge and synchronous signal technology, which is applied in the direction of measuring devices, overload protection devices, measuring electricity, etc., can solve the problems of high external environmental requirements, difficult acquisition of synchronous signals, complicated operation, etc., and achieve safe and convenient extraction of signals, and external The effect of small interference change and accurate power frequency signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

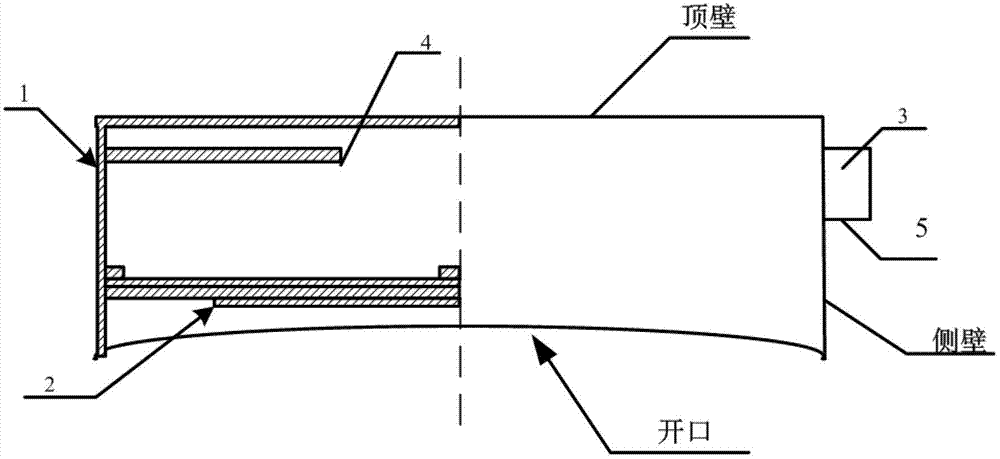

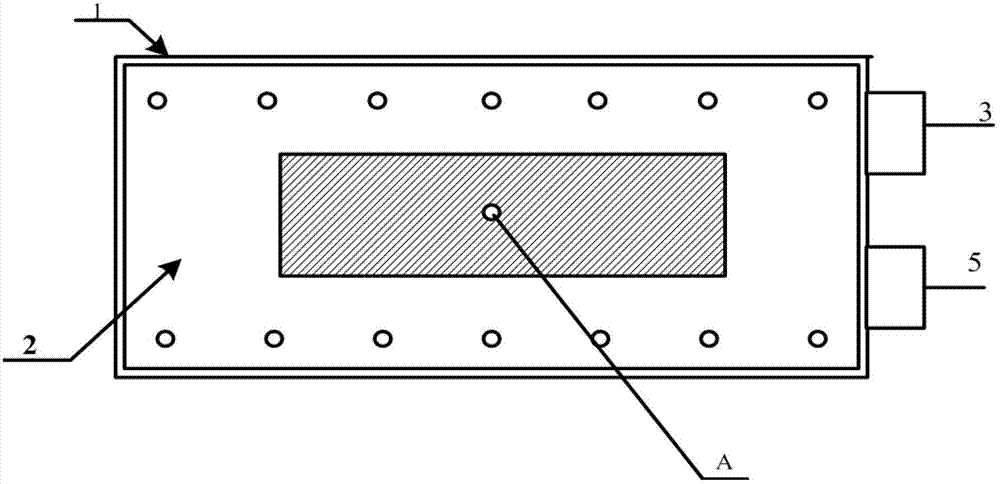

[0034] refer to figure 1 and figure 2 , the present invention includes a metal shielding shell 1, a sensor 2, a coaxial cable connector 3, an integrated circuit board 4 and a power connector 5. The sensor 2 is fixed at the opening of the shielding case 1, the integrated circuit board 4 is arranged between the sensor 2 and the top wall of the shielding case 1, the sensor 2 is connected to the integrated circuit board 4 through the coaxial line, and the output signal of the integrated circuit board 4 passes through Coaxial cable connector 3 output.

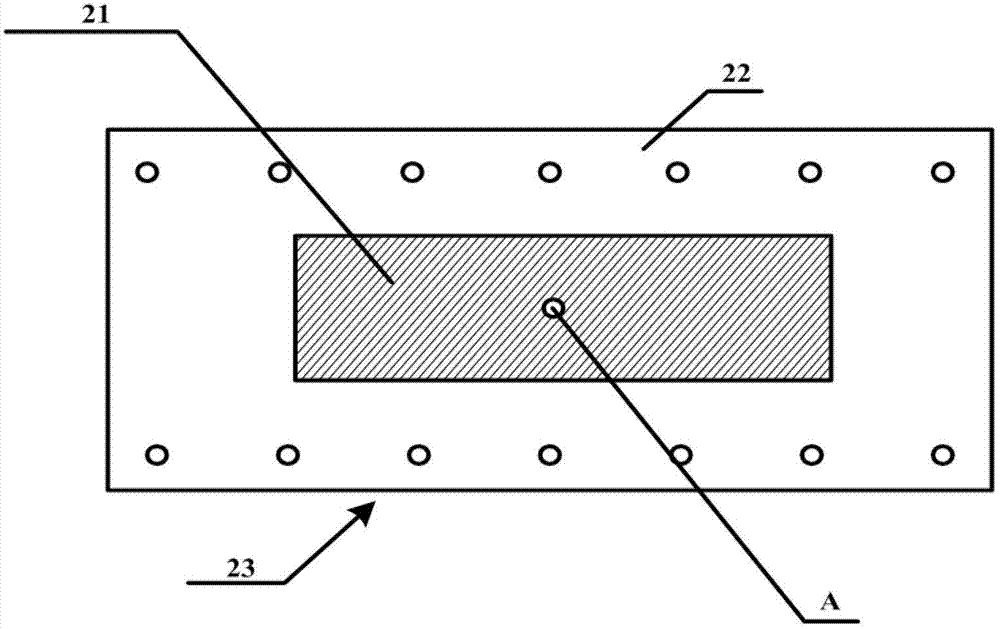

[0035] refer to image 3 and Figure 4 , the sensor 2 adopts a rectangular patch antenna, the rectangular patch antenna is composed of a conductor patch 21, a dielectric substrate 22 and a ground plate 23, the conductor patch 21 is arranged on the dielectric substrate 22, and the dielectric substrate 22 is placed on the ground plane 23. The conductor patch 21 is a rectangular piece with a length of 90mm and a width of 30mm. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com