Pneumatic-control optical limiter

A technology of air pressure control and optical limiting, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems that the optical limiter or material cannot be adjusted in real time, it is difficult to meet the use requirements, and the changeable application environment, etc., achieves Real-time light clipping, easy operation, and stable adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

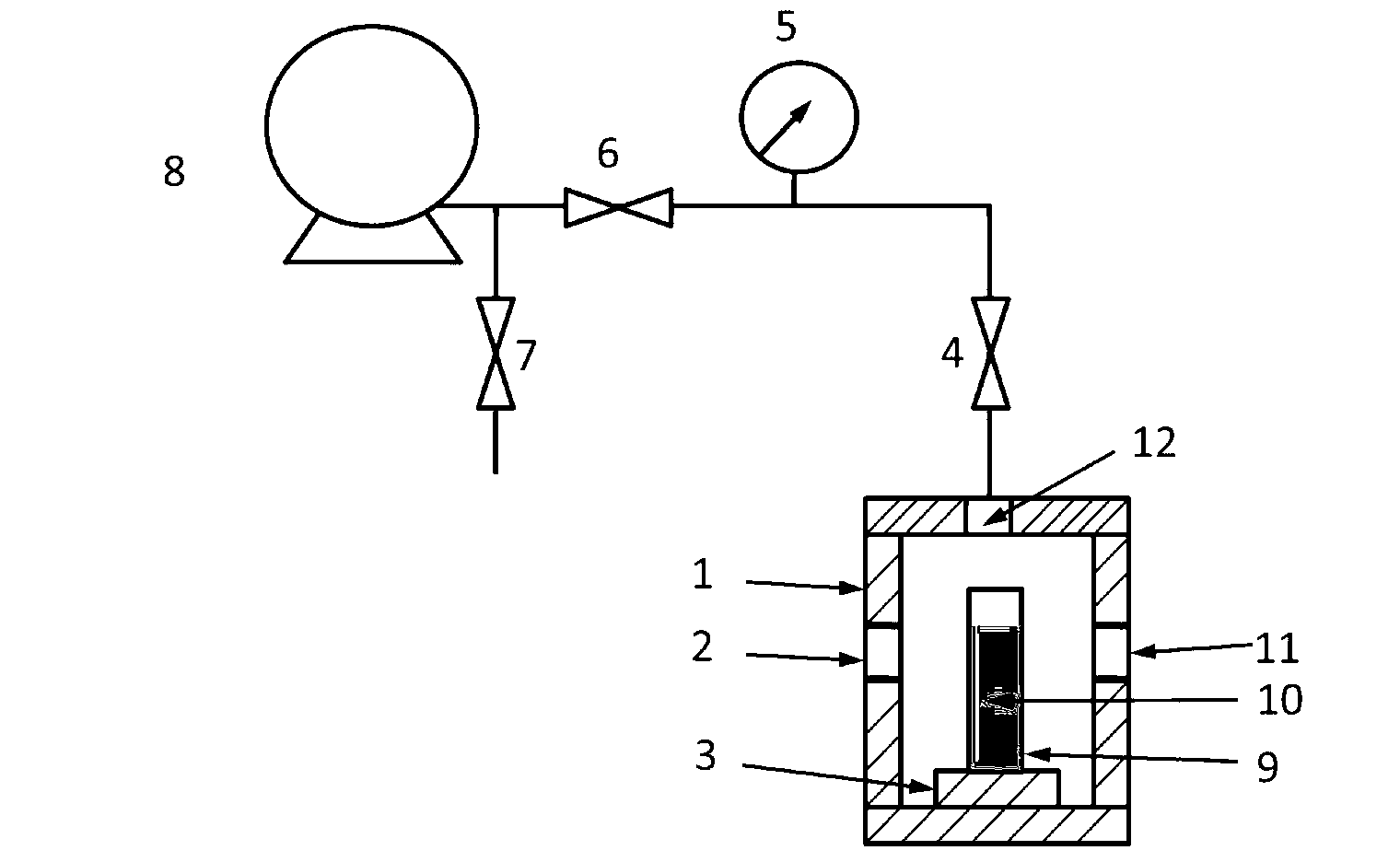

[0018] see first figure 1 , figure 1 It is the schematic diagram of the device of embodiment 1 of the optical limiter controlled by air pressure of the present invention. As can be seen from the figure, the optical limiter controlled by air pressure of the present invention comprises a cylindrical sealed cavity 1, and the opposite surface of the sealed cavity 1 is provided with a first The transparent window 2 and the second transparent window 11 are provided with a cylindrical sample stage 3 at the center of the bottom surface in the sealed chamber 1; a rectangular parallelepiped transparent container 9 is arranged at the center of the cylindrical sample stage 3, and the transparent container 9 The two opposite surfaces are parallel to the first transparent window 2 and the second transparent window 11; a nonlinear scattering medium 10 is installed in the transparent container, and the nonlinear scattering medium 10 is dispersed in an organic solvent or a surfactant solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com