Disassembling processing method of waste sodium-sulfur cells

A technology of sodium-sulfur battery and treatment method, applied in battery recycling, solid waste removal, recycling by waste collectors, etc., to achieve the effect of simple operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with examples.

[0019] When the capacity of the sodium-sulfur battery decays to 80% of the initial capacity, the sodium-sulfur battery is considered unusable. For example, for a sodium-sulfur battery with a rated capacity of 50Ah, when the charge and discharge capacity of the battery decreases to 40Ah, the service life of the battery is considered to be terminated, and it is a waste sodium-sulfur battery.

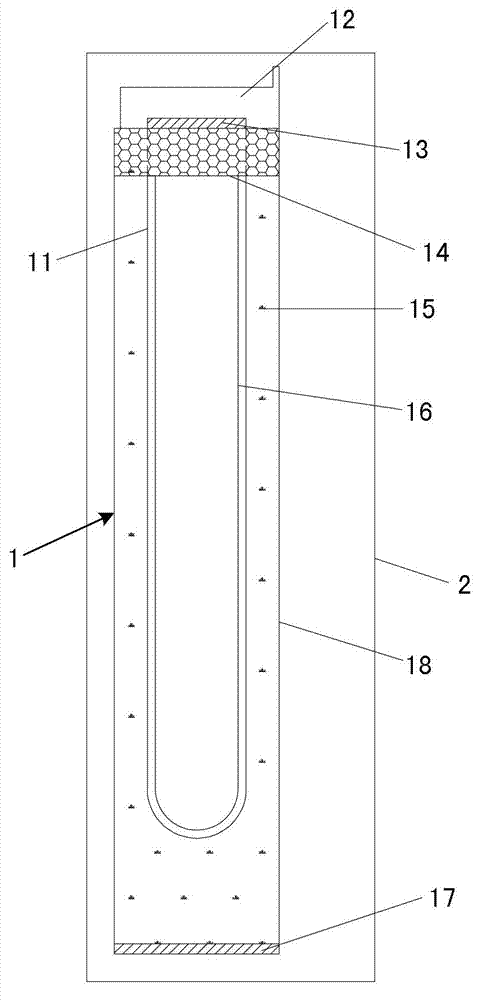

[0020] see figure 1 The sodium-sulfur battery includes an electric furnace 2 and a battery body 1 disposed in the electric furnace 2, the battery body 1 includes a casing 18, an electrolyte ceramic tube 11 disposed in the casing 18, and a negative electrode core tube 16 disposed in the electrolyte ceramic tube 11 , the negative electrode cover 13 located on the upper part of the electrolyte ceramic tube 16 nozzles, the lower sealing part 14 located on the lower part of the electrolyte ceramic tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com