Porous implant material

A technology of implants and porous metals, applied in prosthesis, medical science, surgery, etc., can solve the problems of making implants close to human bones, and achieve the effects of avoiding stress shielding, easy access, and ensuring combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

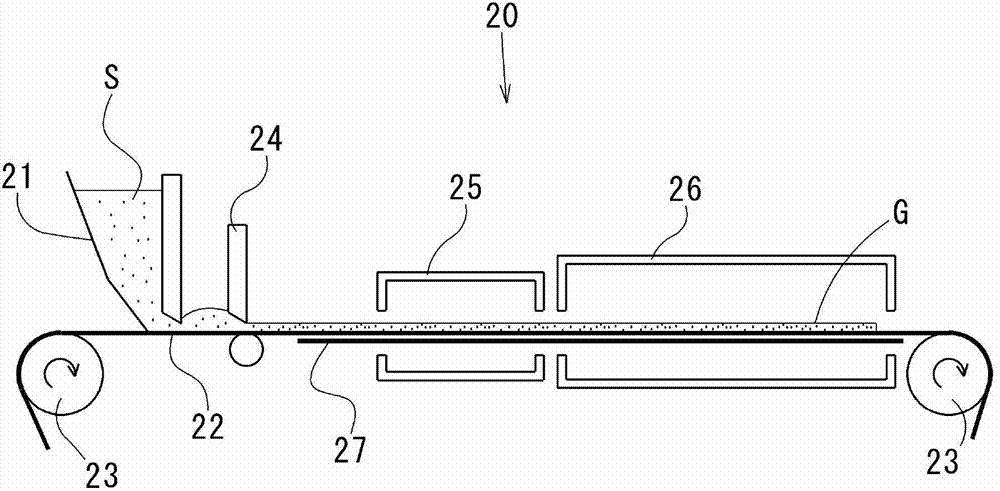

[0067] A green sheet was produced by the slurry foaming method, and a porous metal body was produced from the green sheet. Titanium metal powder with an average particle size of 20 μm (as raw material), polyvinyl alcohol (as binder), glycerin (as plasticizer), alkylbenzene sulfonate (as surfactant), heptane (as foaming agent) was kneaded with water as a solvent to prepare a slurry. This slurry was molded into a plate shape and dried, and then a plurality of green sheets were laminated, degreased, and sintered to obtain a laminated body of a porous metal body.

[0068] The laminated body of the porous metal body was compressed with a calender, and the surface and the cross-section in the thickness direction were observed with an optical microscope.

[0069] Figure 4 is a photo of the surface, Figure 5 It is a photograph of the section. As is apparent from these figures, the pores opening on the surface are approximately circular, but the cross-section is flattened in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com