Janus nano material with double properties and preparation method of Janus nano material

A nanomaterial, mass percentage technology, applied in the field of Janus nanomaterials and its preparation, can solve the problems of harsh preparation conditions, difficult to obtain Janus nanoparticles, and unstable nanoparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

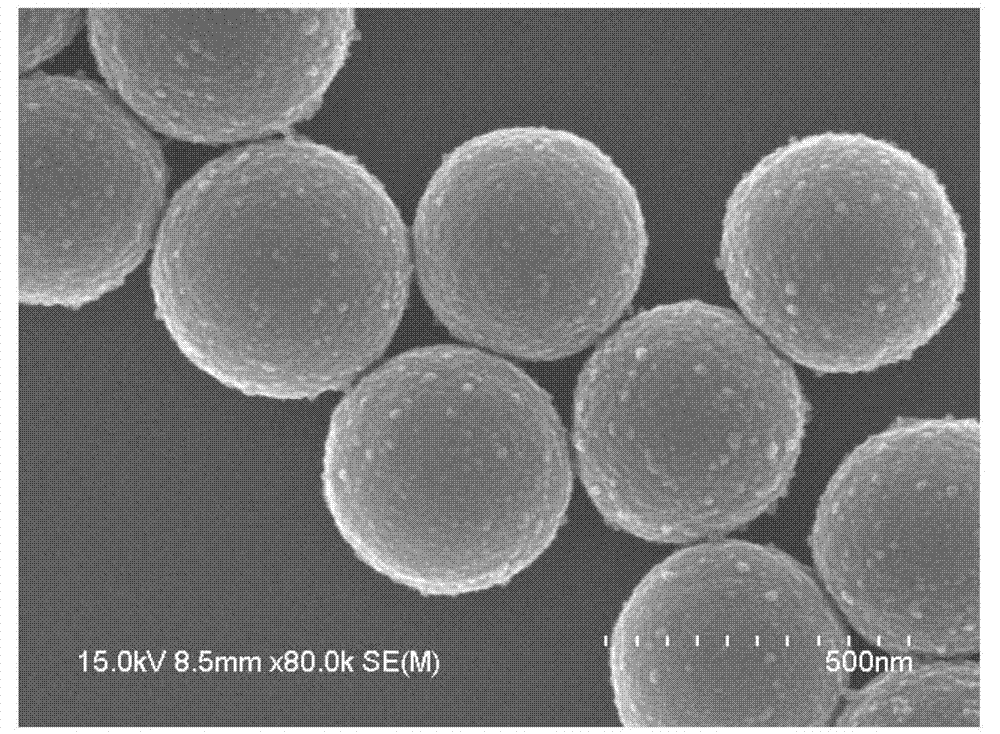

[0090] Example 3, use the emulsion system a2 to prepare Janus nanomaterials whose appearance is particles according to the second method

[0091] 1) According to the step 1) of Example 1, only the emulsion system a1 was replaced with the emulsion system a2 of the following composition to obtain Janus particles a2:

[0092] 0.65g ethyl orthosilicate, 0.112g aminopropyltriethoxysilane, 0.150g phenyltriethoxysilane, 0.65g polar solvent toluene, 0.125g emulsifier sodium dodecylsulfonate and 12.5 After mixing g water, use a high-speed shear emulsifier to emulsify at 1000 rpm for 2 minutes to obtain an emulsion system. In this emulsion system, the mass percent concentration of the inorganic precursor is 4.6%, and the mass percent concentration of the silane coupling agent is 1.8% %, the mass percentage concentration of polar solvent toluene is 4.6%, and the mass percentage concentration of emulsifier sodium dodecylsulfonate is 0.9%;

[0093] 2) Removing the template polystyrene in ...

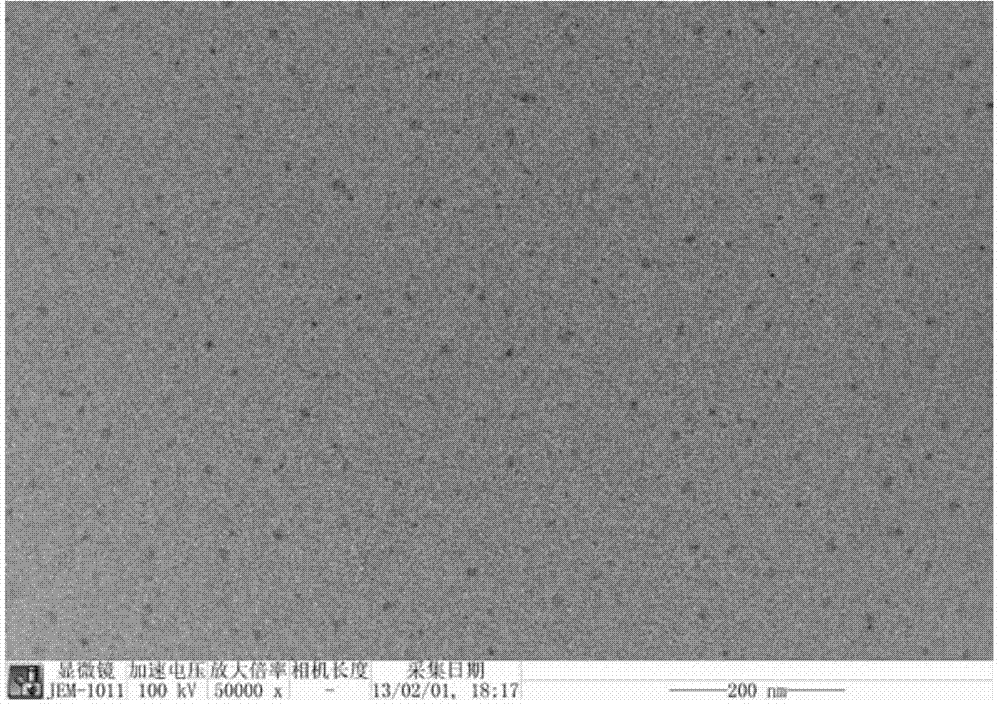

Embodiment 4

[0096] Example 4, using the emulsion system a3 to prepare Janus nanomaterials whose appearance is particles according to method 2

[0097] 1) According to step 1) of Example 3, only the emulsion system a2 used was replaced with the emulsion system a3 of the following composition to obtain Janus particles a3:

[0098] 0.65g ethyl orthosilicate, 0.112g aminopropyltriethoxysilane, 0.155g 3-(methacryloxy)propyltrimethoxysilane, 0.125g emulsifier sodium dodecylsulfonate, After mixing 0.125g of emulsifier Tween80 and 12.5g of water, use a high-speed shear emulsifier to emulsify at 1000rpm for 2min to obtain an emulsion system. In this emulsion system, the mass percentage concentration of the inorganic precursor is 4.8%, and the silane coupling agent The total mass percentage concentration of the emulsifier is 2.0%, the mass percentage concentration of the emulsifier sodium lauryl sulfate is 0.9%, and the mass percentage concentration of the emulsifier Tween80 is 0.9%;

[0099] 2) R...

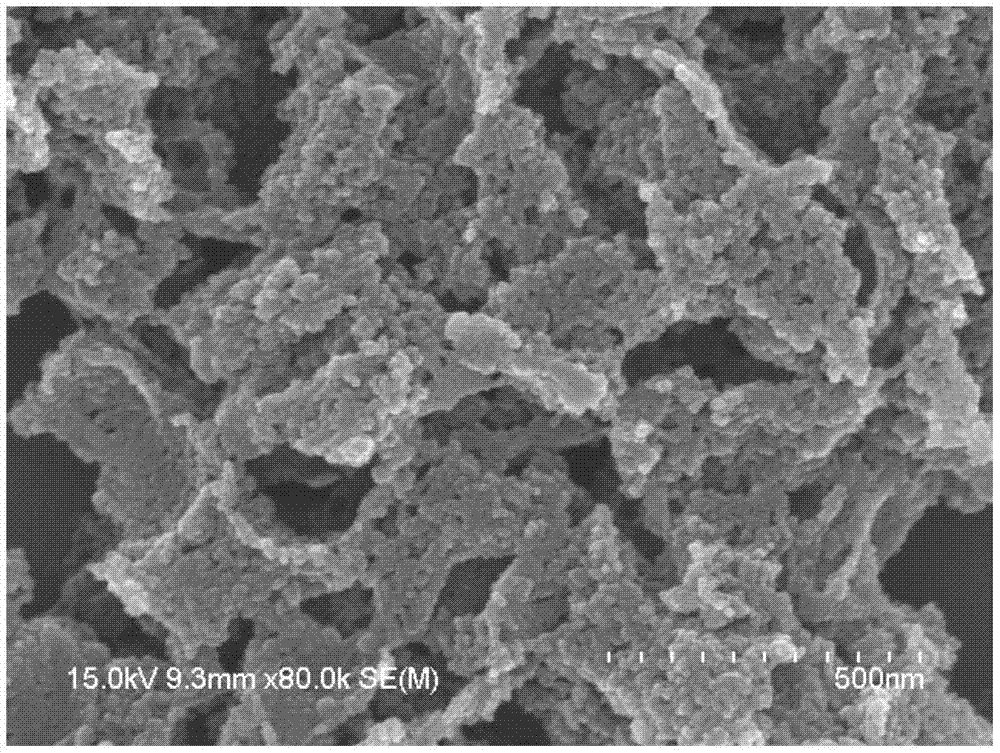

Embodiment 5

[0102] Example 5, using the emulsion system a3 to prepare Janus nanomaterials whose appearance is particles according to method 2

[0103] According to the steps of Example 4, only the silane coupling agent 0.155g 3-(methacryloyloxy)propyltrimethoxysilane in the emulsion system a3 used is replaced by 0.150g phenyltriethoxysilane, then the In the emulsion system a3, the mass percent concentration of the inorganic precursor orthosilicate is 4.8%, and the total mass percent concentration of the silane coupling agent aminopropyltriethoxysilane and phenyltriethoxysilane is 1.9%, the mass percentage concentration of emulsifier sodium lauryl sulfate is 0.9%, the mass percentage concentration of emulsifier Tween80 is 0.9%;

[0104]The above material is SiO with aminopropyl modification on one side and phenyl modification on the other side 2 composition, and aminopropyl, phenyl and SiO 2 They are all connected by -Si-O-Si-bonds, and the molar ratio of aminopropyl group to phenyl grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com