Method and apparatus for source sludge reduction based on microwave sludge pretreatment

A pretreatment and microwave source technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of reactor design and production, unfavorable treatment technology and economicalization, and achieve easy Operation, reduced energy consumption, and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

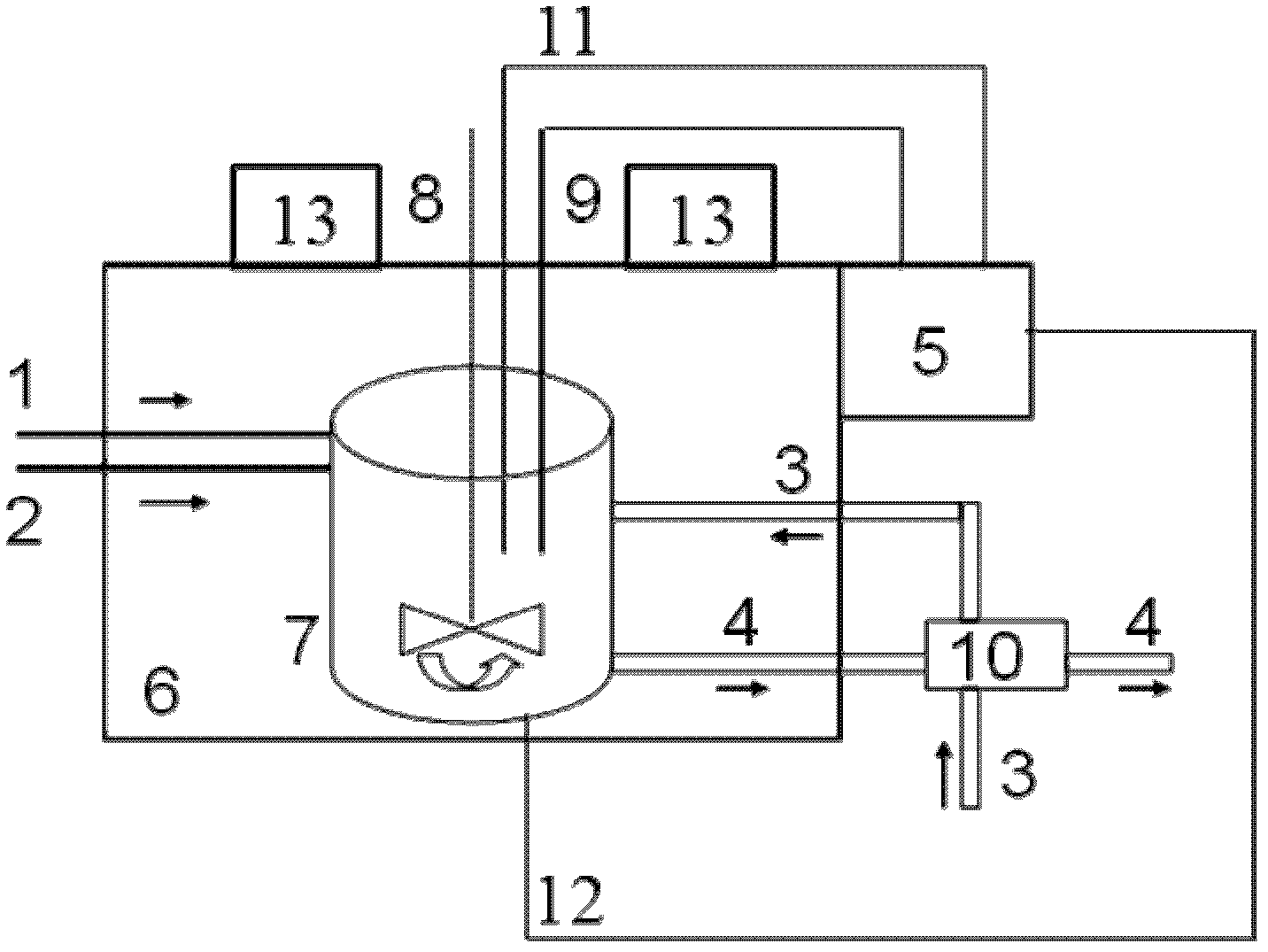

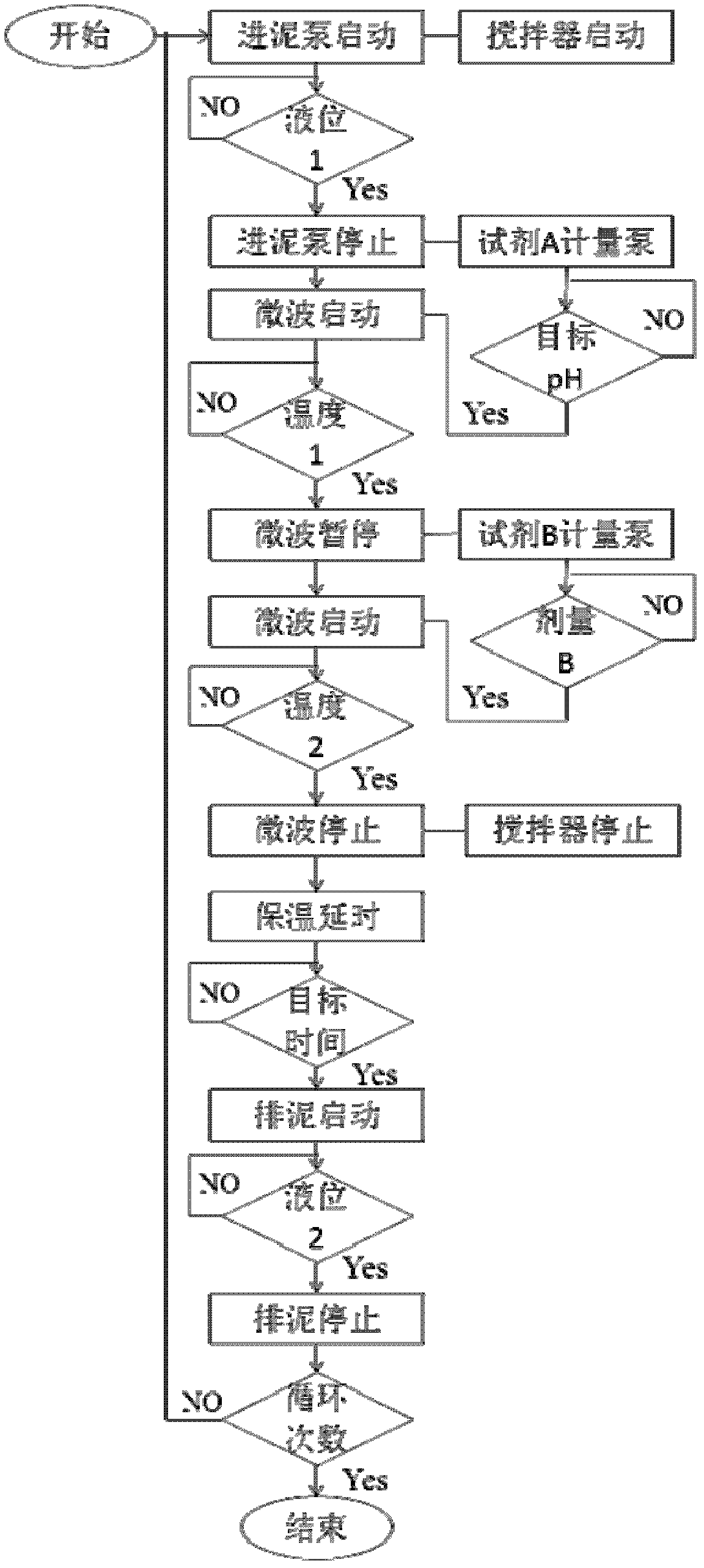

[0060] See figure 2 , the microwave sludge pretreatment device mainly includes a heat exchanger, a microwave reactor and a PLC automatic control system;

[0061] A reaction vessel 7 is built in the furnace cavity 6 of the microwave reactor with PLC control system 5 and microwave source 13 (configuration 2450MHz or 915MHz microwave source), on the furnace cavity wall of the microwave reactor There is an inlet 1 for inorganic lye or inorganic acid and a dosing port 2 for hydrogen peroxide, and the inlet 1 for the inorganic lye or inorganic acid and the dosing port 2 for hydrogen peroxide are respectively Connect with the inlet of the inorganic lye or the inorganic acid solution that has on the wall of described reaction vessel 7 and the dosing port of hydrogen peroxide through pipeline; Also have sludge on the wall of described reaction vessel 7 feed inlet 3 and sludge outlet 4, and the sludge inlet is higher than the sludge outlet;

[0062] The heat exchanger is arranged out...

Embodiment 2

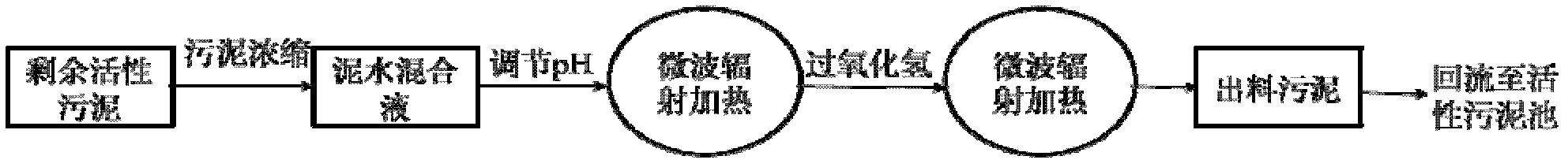

[0070] (1) Concentrating the residual activated sludge of 10g / L-20g / L obtained by utilizing the oxidation ditch method to treat sewage in urban sewage treatment plants to a mud-water mixture with a concentration of 25g / L-30g / L;

[0071] (2) The mud-water mixture obtained in step (1) is preheated through a heat exchanger and then transported to a microwave reactor (the microwave reactor is configured with a microwave source of 2450MHz or 915MHz), and the mud-water is mixed with HCl aqueous solution After the pH of the liquid is adjusted to 3, it is preheated by a heat exchanger and then transported to a microwave reactor;

[0072]Turn on the microwave source of the microwave reactor, stir the mud-water mixture in the microwave reactor while heating it with microwave radiation, and heat the mud-water mixture to a temperature of 60-70°C at a heating rate of 5-20°C / min , turn off the microwave source of the microwave reactor, temporarily stop microwave radiation heating, add hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com