Method for removing silicon thick-film on silicon carbide substrate

A silicon carbide and substrate technology, which is applied in the field of removing silicon thick films on silicon carbide substrates, can solve the problems of long cycle time, long time consumption, and changes in the shape of the mirror blank of the silicon carbide substrate, so as to overcome the long cycle time and improve processing efficiency , the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

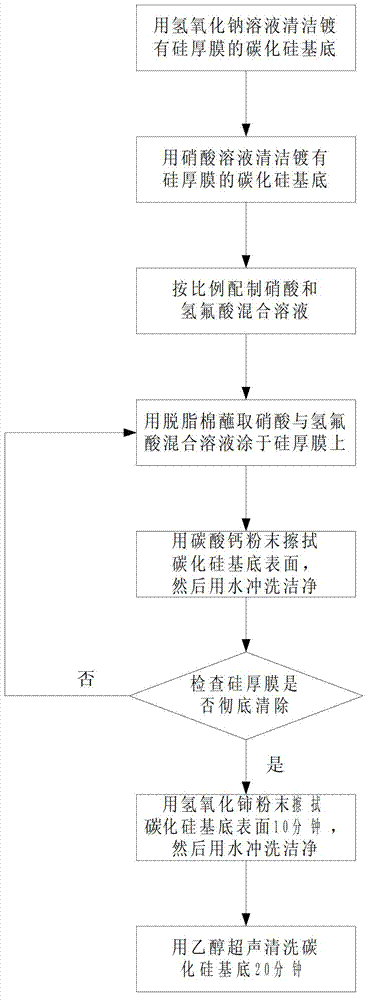

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the method for removing the thick silicon film on the silicon carbide substrate of the present invention comprises the following steps:

[0021] Step 1: Dilute the sodium hydroxide solution with a mass percentage concentration of 50% and water according to the volume ratio of 1:10 to form a dilute sodium hydroxide solution, and then use the prepared dilute sodium hydroxide solution to clean the silicon carbide coated with a silicon thick film Base 10 minutes;

[0022] Step 2: Prepare a dilute nitric acid solution with nitric acid with a concentration of 68% by mass and water at a volume ratio of 1:3, and clean the silicon carbide substrate coated with a silicon thick film for 5 minutes with the prepared dilute nitric acid solution;

[0023] Step 3: Prepare a mixed solution of nitric acid and hydrofluoric acid at a volume ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com