Method for preparing batch annealing low-grade non-oriented electrical steel

A technology of oriented electrical steel and bell annealing, which is applied in the field of electrical steel, can solve the problems of increasing production costs and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

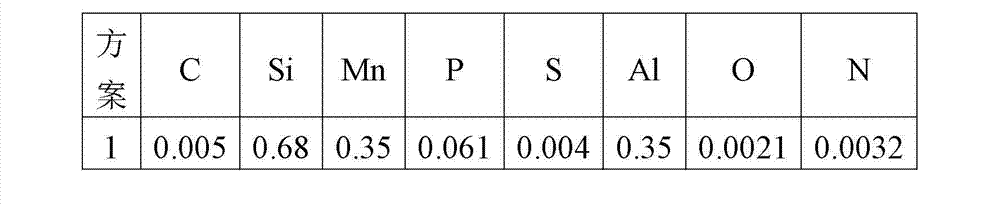

[0011] The chemical composition of the continuous casting slab is as follows:

[0012] Table 1 Chemical composition of continuous casting slab Unit: % (mass)

[0013]

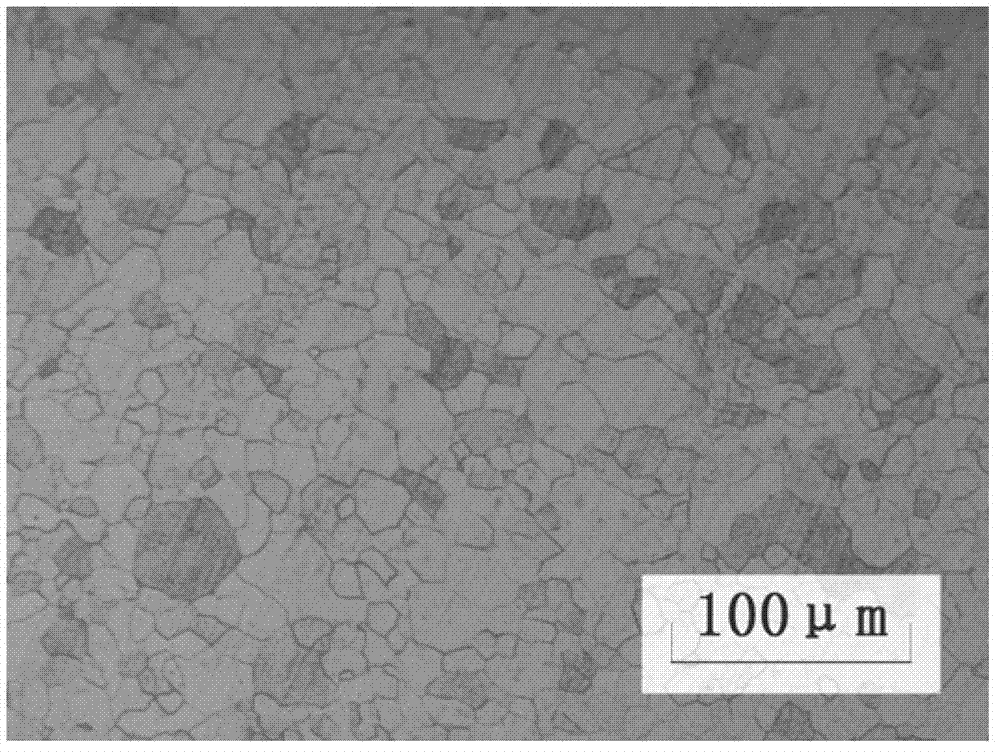

[0014] The thickness of the hot-rolled steel strip is 3.0mm. The air-cooled hot-rolled steel strip is pickled and then cold-rolled. After continuous cold rolling, the reduction rate is 3.6~36.0%. The steel coil after cold-rolling is protected by 75% nitrogen and 25% hydrogen bell annealing furnace annealing, the annealing temperature is 690 ~ 730 ℃, to obtain the required electromagnetic properties and texture. The annealed steel coil is coated with a semi-organic coating to ensure the insulation and interlayer resistance of the punched steel plate.

[0015] Table 2 Iron loss value and magnetic properties of the product

[0016]

Embodiment 2

[0018] The chemical composition of the continuous casting slab is as follows:

[0019] Table 3 Chemical composition of continuous casting slab Unit: % (mass)

[0020]

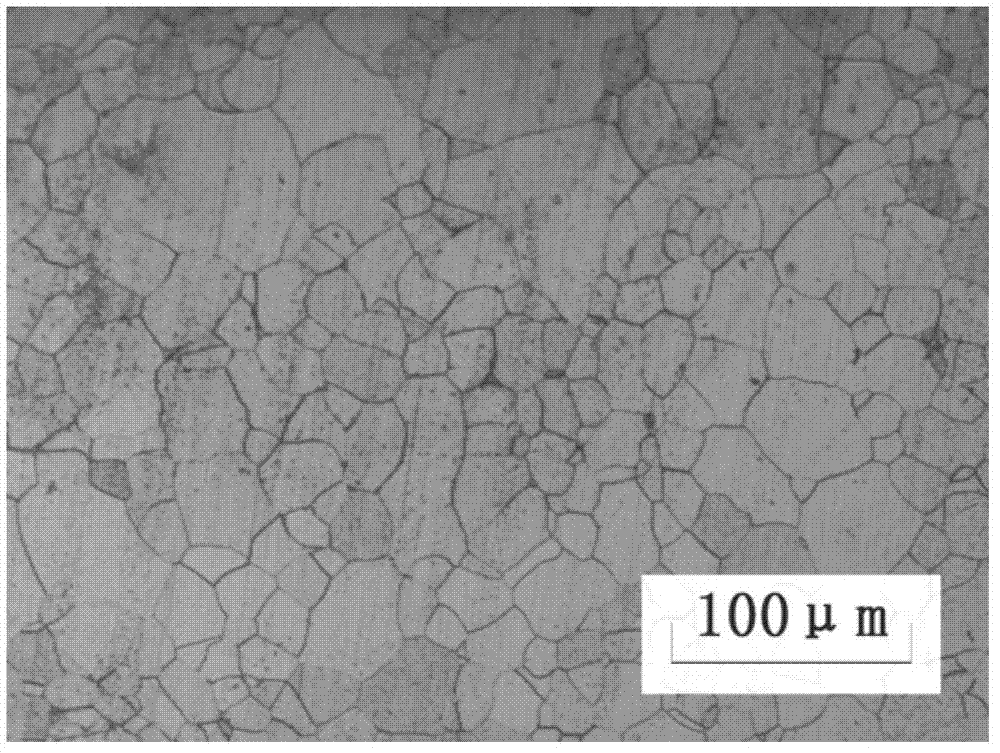

[0021] The thickness of the hot-rolled steel strip is 3.0mm. The air-cooled hot-rolled steel strip is pickled and then cold-rolled. After continuous cold rolling, the reduction rate is 3.6~36.0%. The steel coil after cold-rolling is protected by 75% nitrogen and 25% hydrogen bell annealing furnace annealing, the annealing temperature is 690 ~ 730 ℃, to obtain the required electromagnetic properties and texture. The annealed steel coil is coated with a semi-organic coating to ensure the insulation and interlayer resistance of the punched steel plate.

[0022] Table 4 Iron loss value and magnetic properties of the product

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com