Ultrahigh-strength and high-elongation Al-Zn-Mg-Cu alloy and method for manufacturing same

An alloy and alloy ingot casting technology, which is applied in the field of ultra-high strength and high elongation Al-Zn-Mg-Cu alloy and its preparation, can solve the problems of low elongation, achieve high elongation, low raw material cost, and industrial application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

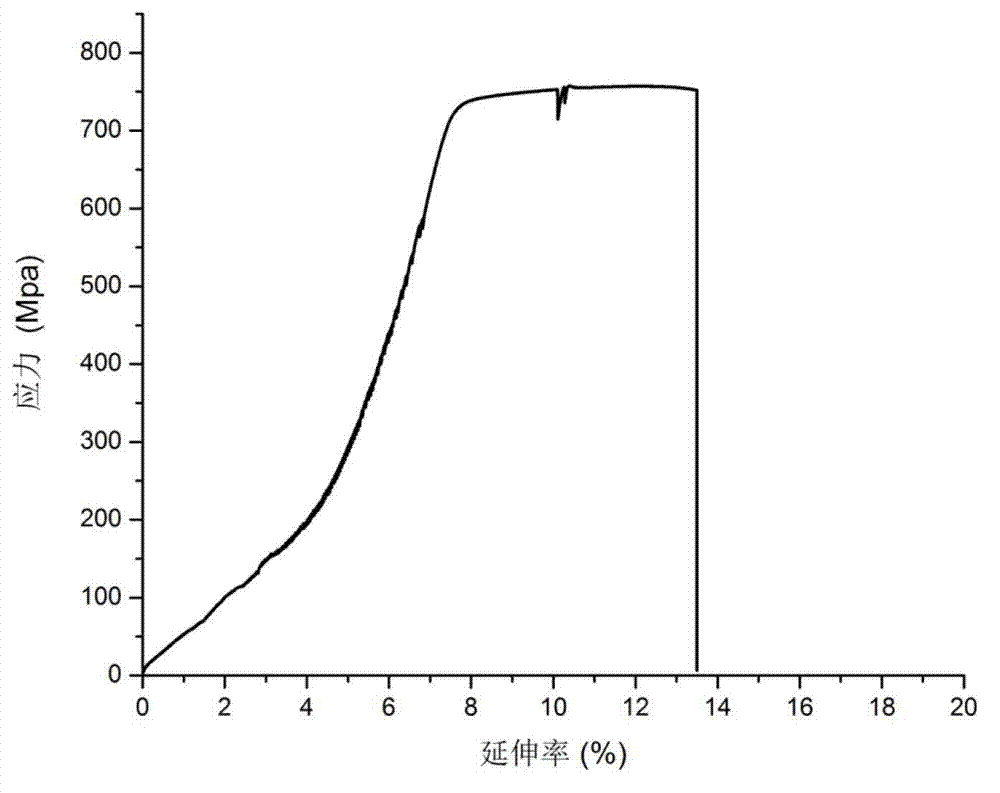

Embodiment 1

[0025] 1) Prepare an alloy according to the nominal composition Al-10Zn-2.0Mg-1.2Cu-0.12Zr (weight percentage, %), in which copper and zirconium elements are added in the form of aluminum-copper and aluminum-zirconium master alloys respectively.

[0026] 2) Wash the prepared raw materials with alcohol and blow dry. Put pure aluminum into a resistance furnace with a temperature of 780°C, and keep the temperature for 30 minutes after melting the aluminum; add aluminum-copper master alloy and aluminum-zirconium master alloy, keep the temperature for 10 minutes; add pure zinc, keep the temperature for 15 minutes; use CCl 6 Degassing, holding for 5min; adding pure magnesium, holding for 5min; using CCl 6 Degassing, heat preservation for 5min; power off the slag, when the melt temperature drops to 720℃, pour the melt into a cylindrical iron mold of Ф100mm at a speed of 1kg / min, thereby obtaining Al-Zn-Mg-Cu Alloy ingots.

[0027] 3) Put the ingot cooled to room temperature into th...

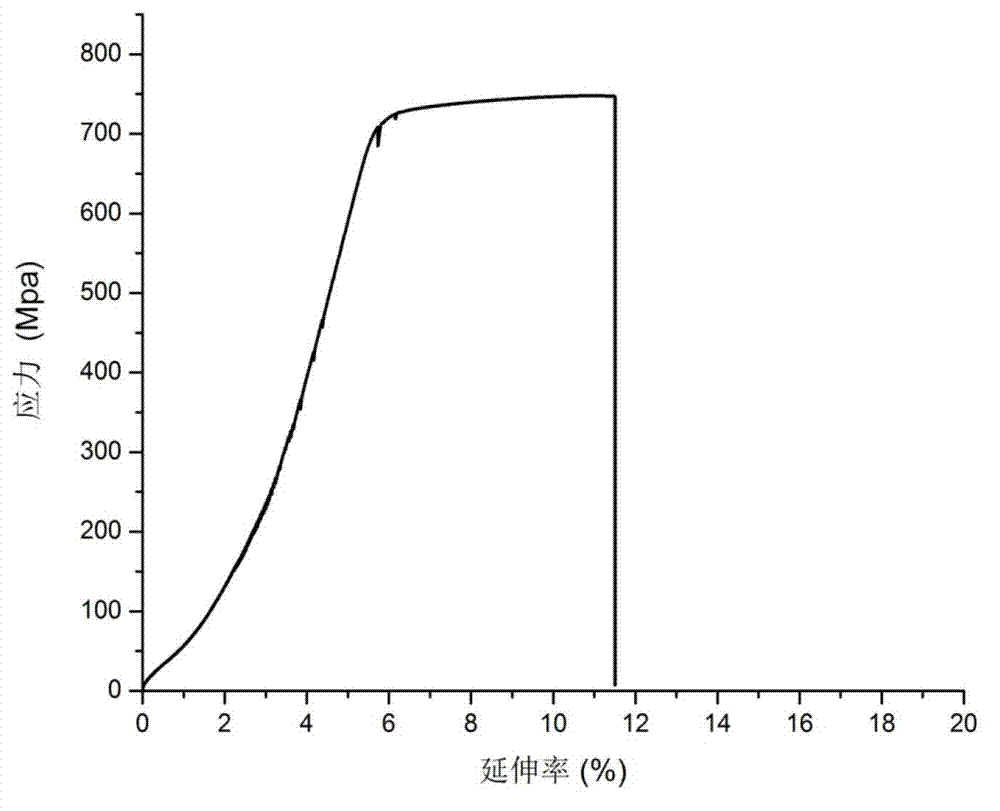

Embodiment 2

[0033] 1) Prepare an alloy according to the nominal composition Al-10Zn-1.9Mg-1.1Cu-0.14Zr (weight percentage, %), in which copper and zirconium elements are added in the form of aluminum-copper and aluminum-zirconium master alloys respectively.

[0034] 2) Wash the prepared raw materials with alcohol, dry them, put the high-purity aluminum into a resistance furnace with a temperature of 780°C, and keep the aluminum for 30 minutes after melting; Pure zinc, keep warm for 15min; use CCl 6 Degassing, holding for 5min; adding pure magnesium, holding for 5min; using CCl 6 Degassing, heat preservation for 5min; power off the slag, when the melt temperature drops to 720℃, pour the melt into a cylindrical iron mold of Ф100mm at a speed of 1kg / min, thereby obtaining Al-Zn-Mg-Cu Alloy ingots.

[0035] 3) Put the ingot cooled to room temperature into the resistance furnace, heat it to the primary annealing temperature of 400°C at a heating rate of 10°C / min and keep it for 4 hours, and ...

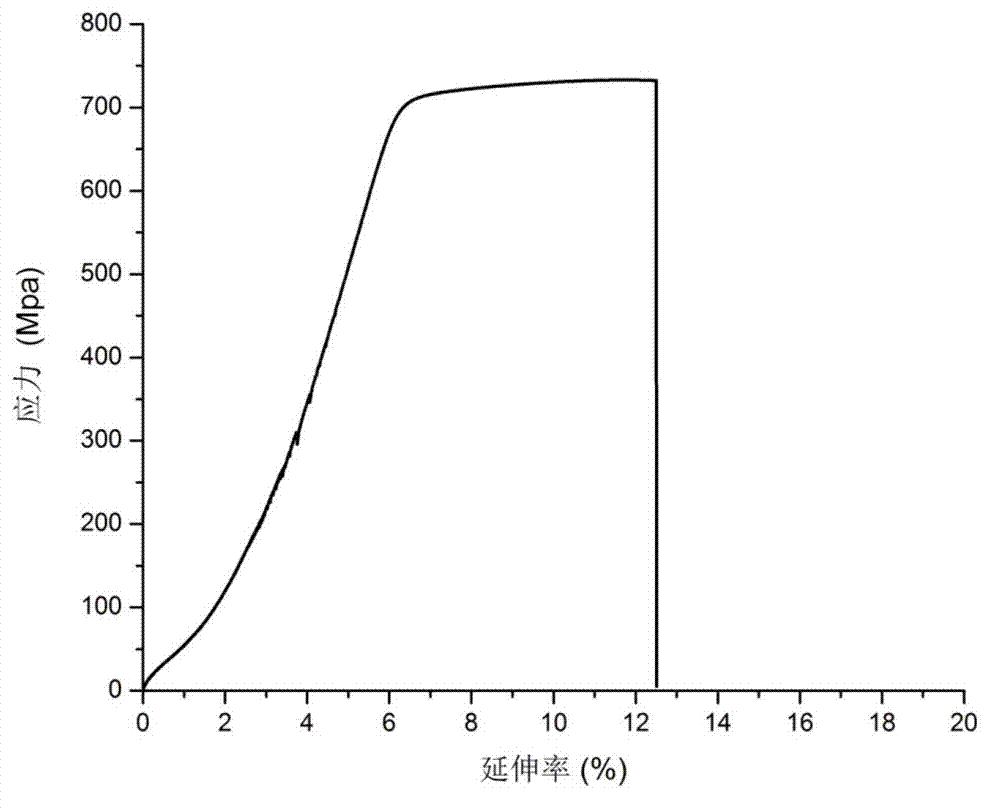

Embodiment 3

[0041] 1) Prepare an alloy according to the nominal composition Al-10Zn-2.1Mg-1.2Cu-0.12Zr (weight percentage, %), in which copper and zirconium elements are added in the form of aluminum-copper and aluminum-zirconium master alloys respectively.

[0042] 2) Wash the prepared raw materials with alcohol, dry them, put the high-purity aluminum into a resistance furnace with a temperature of 780°C, and keep the aluminum for 30 minutes after melting; Pure zinc, keep warm for 15min; use CCl 6 Degassing, holding for 5min; adding pure magnesium, holding for 5min; using CCl 6 Degassing, heat preservation for 5min; power off the slag, when the melt temperature drops to 720℃, pour the melt into a cylindrical iron mold of Ф100mm at a speed of 1kg / min, thereby obtaining Al-Zn-Mg-Cu Alloy ingots.

[0043] 3) Put the ingot cooled to room temperature into the resistance furnace, heat it to the primary annealing temperature of 400°C at a heating rate of 10°C / min and keep it for 4 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com