Capacitive electromagnetic flowmeter

An electromagnetic flowmeter, capacitive technology, applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, measurement flow/mass flow, etc., can solve the problem that the excitation current of capacitive electromagnetic flowmeter cannot be further improved And other problems, to achieve the effect of increasing the excitation voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

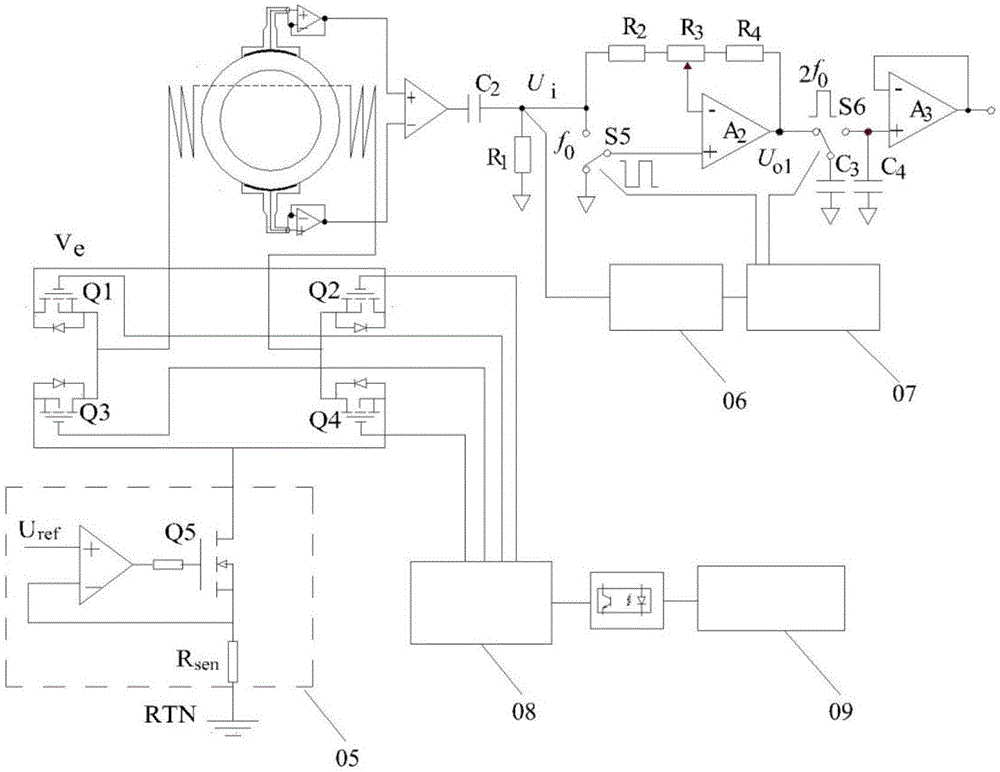

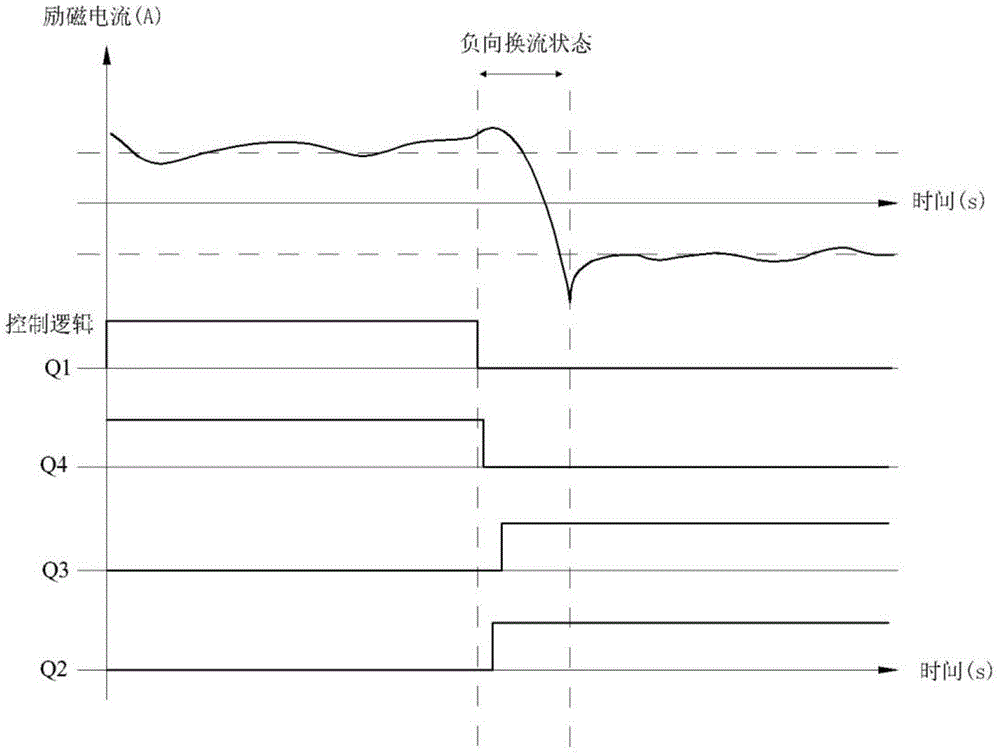

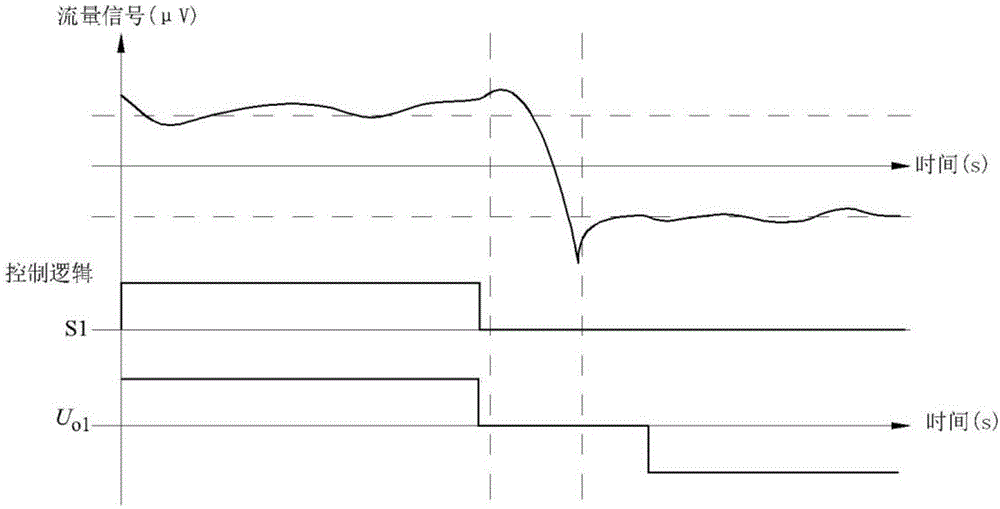

[0041] like Figure 4 or Figure 5 As shown, the capacitive electromagnetic flowmeter includes a capacitive sensor 1, a pre-op amplifier circuit 11, a flow signal processing circuit 10, a full-bridge inverter circuit 6, a full-bridge drive circuit 8, and an excitation current feedback circuit 7, as shown The excitation current feedback circuit 7 includes a first excitation current feedback circuit 7A, a second excitation current feedback circuit 7B and a timing control circuit 9;

[0042] The capacitive sensor includes a lining layer 1A, the outer wall of the lining layer is uniformly provided with a first detection electrode 2A, a second detection electrode 2B, a first excitation coil 4A and a second excitation coil 4B, and the first The detection electrode 2A is arranged opposite to the second detection electrode 2B, the first excitation coil 4A and the second excitation coil 4B are oppositely arranged, and the first detection electrode 2A and the second detection electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com