Glass medium model imitating rock core structure

A core and glass technology, applied in the field of glass medium models, can solve the problems of high processing difficulty and high production cost, and achieve the effects of reduced production cost, reduced production cost, and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

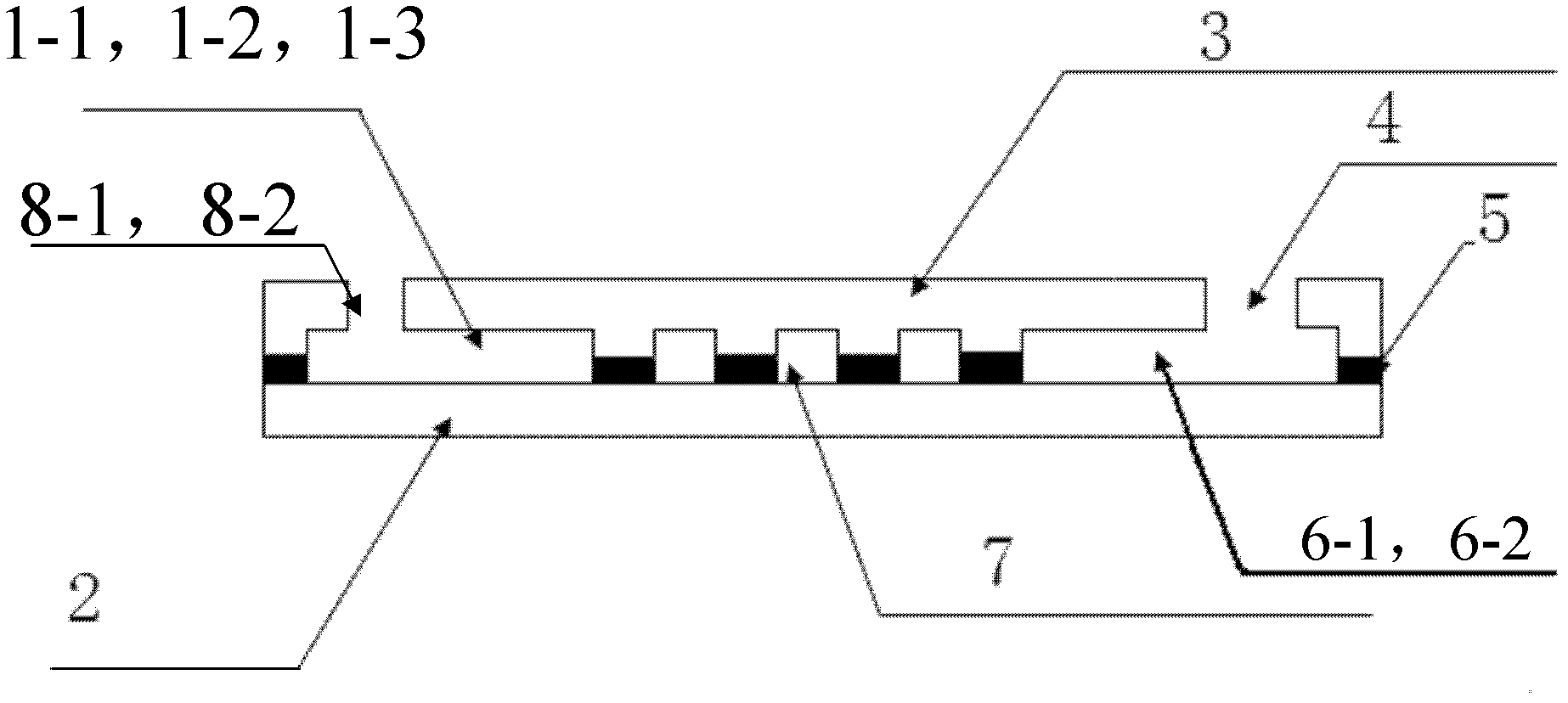

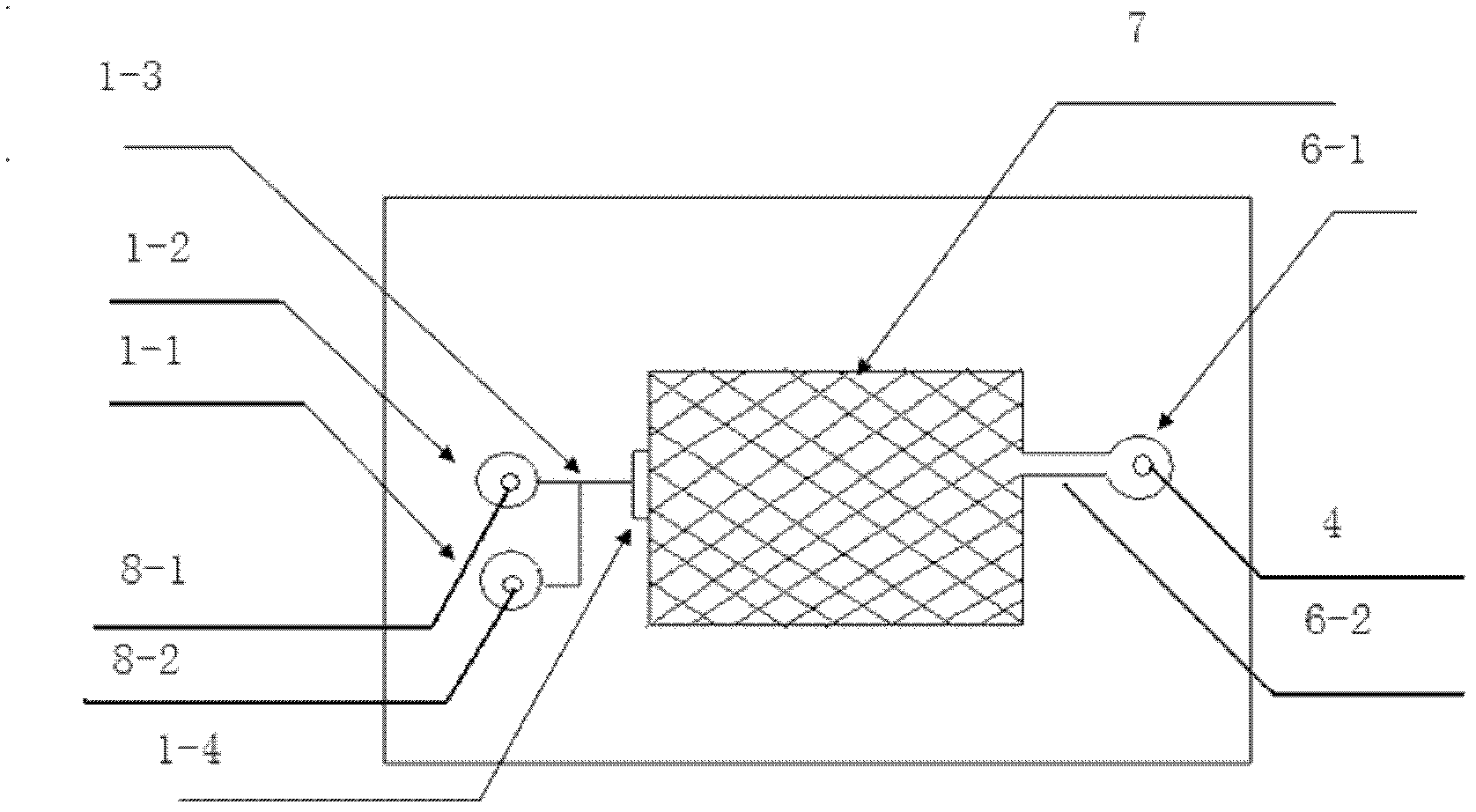

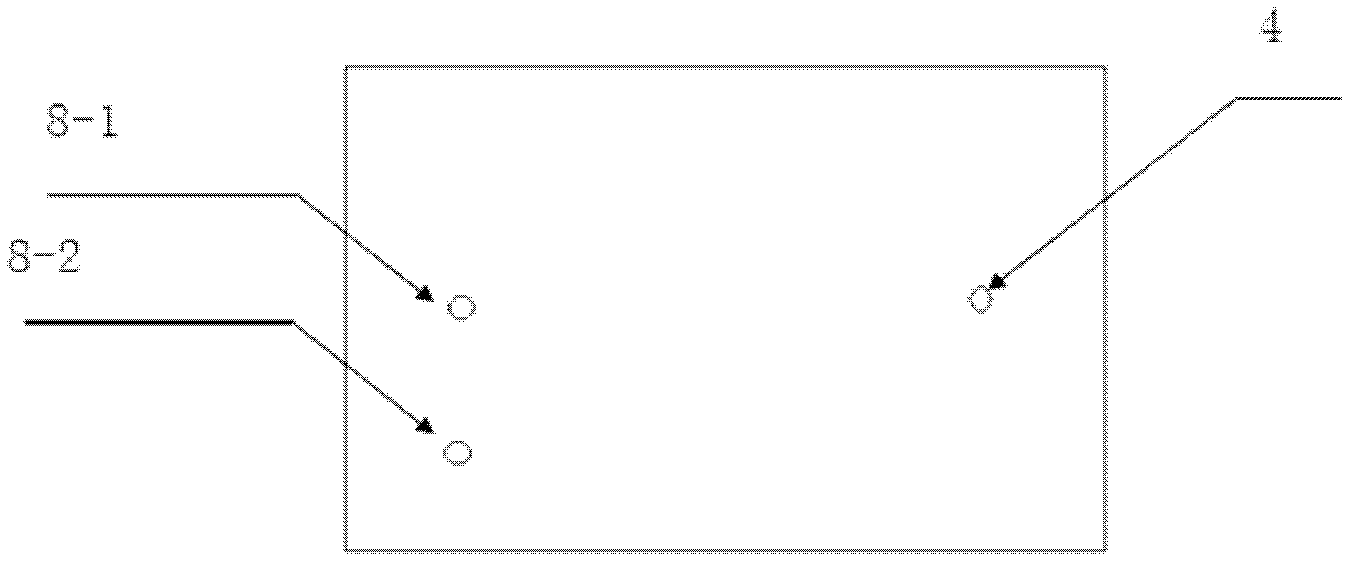

[0054] Please refer to Figure 1(a), Figure 1(b) and figure 2 , a glass medium model imitating rock core structure formed by sealing the glass cover and the glass substrate through UV-cured adhesive NOA 61 is a rectangle with a length of 5 cm and a width of 3.8 cm (UV-cured adhesive The thickness of the adhesive layer 5 is 0.5 micron), including the first liquid inlet pool 1-1, the second liquid inlet pool 1-2, a thickness of 2.3 millimeters, a length of 5 centimeters, and a width of 3.8 centimeters glass substrate 2, A glass cover sheet 3 with a thickness of 2.3 mm, a length of 5 cm, and a width of 3.8 cm, a drain hole 4, a drain pool 6-1, a drain pool channel 6-2, a microscopic channel imitating a rock core structure 7, and the first Liquid inlet hole 8-1, second liquid inlet hole 8-2, microbubble generating module 1-3 and microbubble splitting module 1-4;

[0055] One end of the glass substrate 2 is respectively etched with a first liquid inlet pool 1-1 and a second liquid...

Embodiment 2

[0071] Please refer to Figure 1(a), Figure 1(b) and figure 2, the present embodiment provides a glass medium model imitating a rock core structure, which includes a cover glass 3, a glass substrate 2, a microbubble generating module 1-3, a microbubble splitting module 1-4, and the first liquid inlet 8 -1, the second inlet hole 8-2, the drain hole 4, the first inlet pool 1-1, the second inlet pool 1-2, the drain pool 6-1, the drain pool channel 6-2, The visible glass medium model of the ultraviolet curing adhesive glue layer 5 and the microscopic channel 7 imitating the rock core structure; wherein, the glass cover sheet is sealed with the glass substrate, the first liquid inlet pool 1-1, the second The liquid inlet pool 1-2, the liquid drainage pool 6-1, the microbubble generating module 1-3, the microbubble splitting module 1-4, and the microscopic channels 7 imitating the rock core structure are all etched on the glass substrate; The liquid hole 8-1, the second liquid inle...

Embodiment 3

[0086] Please refer to Figure 1(a), Figure 1(b) and figure 2 , the present embodiment provides a glass medium model imitating a rock core structure, which includes a cover glass 3, a glass substrate 2, a microbubble generating module 1-3, a microbubble splitting module 1-4, and the first liquid inlet 8 -1, the second inlet hole 8-2, the drain hole 4, the first inlet pool 1-1, the second inlet pool 1-2, the drain pool 6-1, the drain pool channel 6-2, The visible glass medium model of the ultraviolet curing adhesive glue layer 5 and the microscopic channel 7 imitating the rock core structure; wherein, the glass cover sheet is sealed with the glass substrate, the first liquid inlet pool 1-1, the second The liquid inlet pool 1-2, the liquid drainage pool 6-1, the microbubble generating module 1-3, the microbubble splitting module 1-4, and the microscopic channels 7 imitating the rock core structure are all etched on the glass substrate; The liquid hole 8-1, the second liquid inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com