Artificial joint bearing surface micro-hole texture capable of improving lubricating performance and abrasion-resistant performance

A technology of artificial joints and surface micropores, applied in joint implants, joint implants, medical science, etc., can solve problems such as prosthesis loosening, adverse biological reactions of body cells, etc., to reduce friction and reduce direct contact area, the effect of reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

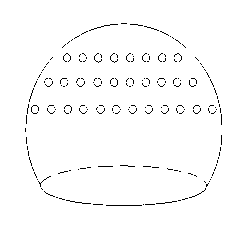

[0025] see figure 1 : A microporous texture on the bearing surface of an artificial joint, comprising a joint head and an acetabular cup of an artificial joint, the material of the joint head and the joint acetabular cup is cobalt-chromium-molybdenum alloy, and the friction surface of the joint head is uniformly distributed with microporous A hole array, the shape of the microholes in the microhole array is circular, and the microholes are of equal size and same depth.

[0026] The diameter of the micropores is 300um, the aspect ratio is 0.12, and the area density of the micropores is 17%.

[0027] The surface-textured joint head is paired with an untreated joint cup, and under the condition of a load of 50 MPa and calf serum as a lubricant, friction and wear tests are carried out using a knee joint simulator. The measured friction coefficient of the joint pair is 0.05, which is lower than that of the all-metal artificial joint with smooth surface (0.07), and the annual wear ...

Embodiment 2

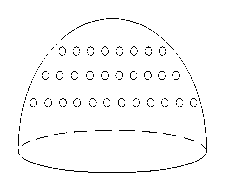

[0029] see figure 1 , figure 2 : A microporous texture on the bearing surface of an artificial joint, comprising a joint head and an acetabular cup of an artificial joint, the material of the joint head and the joint acetabular cup is a cobalt-chromium-molybdenum alloy, and the grinding of the joint head and the joint acetabular cup Microhole arrays are uniformly distributed on the surface, and the shape of the microholes in the microhole array is circular, and the microholes are of equal size and same depth.

[0030] The diameter of the micropores is 120um, the aspect ratio is 0.1, and the area density of the micropores is 10%.

[0031] The surface-textured joint head and the surface-textured joint acetabular cup pair were subjected to a friction and wear test using a knee joint simulator under the condition of a load of 50 MPa and calf serum as a lubricant. The measured friction coefficient of the joint pair is 0.06, which is lower than that of the smooth surface all-meta...

Embodiment 3

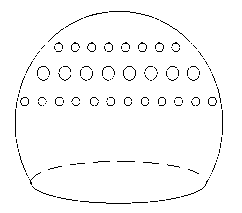

[0033] see image 3 : A microporous texture on the bearing surface of an artificial joint, comprising a joint head and an acetabular cup of an artificial joint, the material of the joint head and the joint acetabular cup is a cobalt-chromium-molybdenum alloy, and micropores are distributed on the friction surface of the joint head The shape of the microholes in the microhole array is circular, and the microholes have different sizes and the same depth.

[0034] The micropores of different sizes are distributed radially and alternately along the friction surface of the joint head.

[0035] The diameter of described smaller micropore is 80um, and aspect ratio is 0.1, and the area density of micropore is 16%; The diameter of described larger micropore is 200um, and aspect ratio is 0.04, and the area density of micropore is 16%. %.

[0036] The surface-textured joint head is paired with an untreated joint cup, and under the condition of a load of 50 MPa and calf serum as a lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com