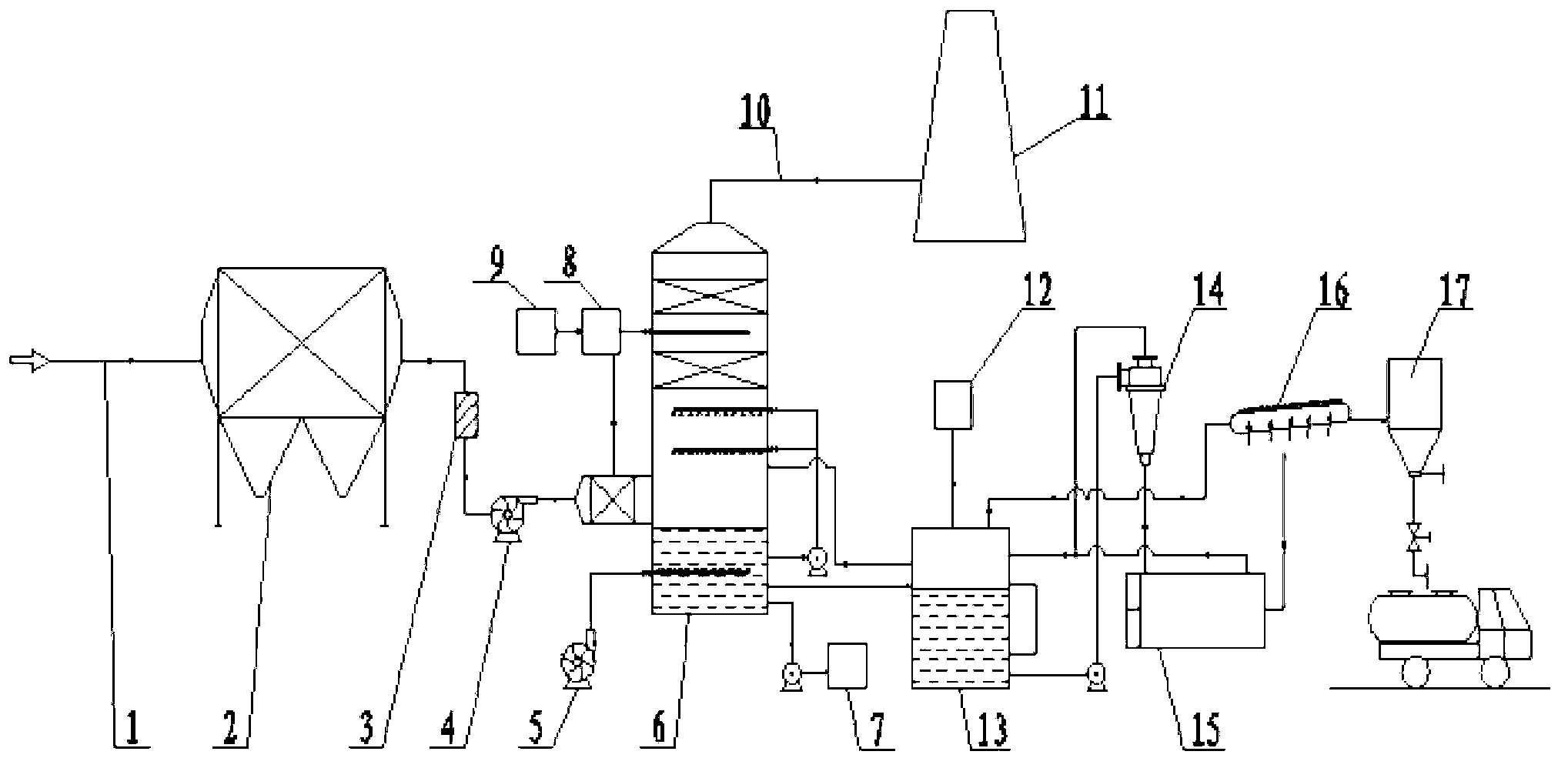

Integrated flue gas dust removal desulfurization and denitrification device

A desulfurization, denitrification, and flue gas technology, which is applied to combined devices, ammonium nitrate, ammonium sulfate, etc., can solve the problems of poor flue gas dust removal effect, incomplete desulfurization and denitrification, etc., and achieve the effect of improving purification efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, one end of the present invention is connected with the flue gas outlet of the industrial coal system through the flue gas input pipe 1, and the other end is connected with the inlet of the electric bag dust collector 2, and the flue gas outlet of the electric bag dust collector 2 It is connected to the entrance of the pre-catalytic oxidizer through the induced draft fan 4 and the cooler 3, the ammonia water supply pump 7 is connected to the slurry circulation pool at the bottom of the desulfurization and denitrification tower 6, and the flue gas outlet at the top of the desulfurization and denitrification tower 6 passes through the flue gas output pipe 10 It is connected with the chimney 11, wherein the purified flue gas is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com