Belt chip cleaning device

A cleaning device and cutting chip technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of easy agglomeration and cannot fundamentally solve the problem of cutting chip accumulation, so as to avoid cutting chips caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

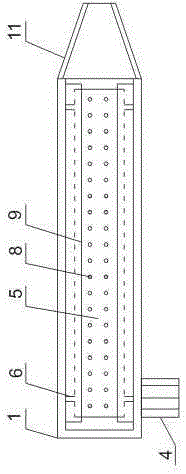

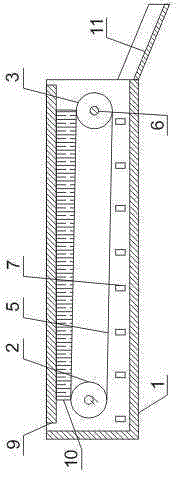

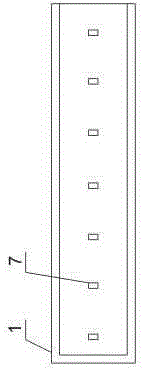

[0036] Such as figure 1 , figure 2 and image 3 As shown, the belt-type chip cleaning device includes a housing 1, a driving pulley 2, a driven pulley 3, a motor 4, a belt 5 and a rotating shaft 6, the top of the housing 1 is open, and one end of the housing 1 is open. The pulley 2 and the driven pulley 3 are fixed in the casing 1 through the rotating shaft 6, the driving pulley 2 is close to the closed end of the casing 1, the driven pulley 3 is close to the open end of the casing 1, and the motor 4 is arranged in the casing Outside the body 1, the rotating shaft 6 connected with the driving pulley 3 is connected with the output shaft of the motor 4, the belt 5 is sleeved on the driving pulley 2 and the driven pulley 3, and the bottom of the housing 1 is provided with an oil leakage hole 7.

[0037] This embodiment is set on both sides of the milling platform, and the cutting chips generated during the milling process will automatically fall on the belt 5, and the cutting ...

Embodiment 2

[0040] Such as figure 1 As shown, in this embodiment, on the basis of the above-mentioned embodiments, the belt 5 is provided with an oil seepage hole 8, and the diameter of the oil seepage hole 8 is 1 mm.

[0041] The oil seepage hole 8 can prevent cooling fluid and cooling oil from accumulating on the belt 5, and can avoid the occurrence of agglomeration of fine cutting chips on the belt 5. The diameter of the oil seepage hole 8 is 1mm, which can prevent the cutting chips on the belt 5 from leaking into the housing 1 from the belt 5, and avoid the trouble of cleaning the housing 1.

Embodiment 3

[0043] Such as figure 1 and figure 2 As shown, on the basis of the above embodiments, this embodiment also includes a brush 10, the top of both sides of the housing 1 is provided with an inwardly extending flange 9, and the brush 10 is vertically fixed on the flange 9 Above, the brush 10 is in contact with the outer surface of the belt 5 .

[0044] The brush 10 can prevent the cutting chips on the belt 5 from falling into the housing 1 from both sides of the belt 5 without hindering the movement of the belt 5 , avoiding the accumulation of cutting chips in the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com