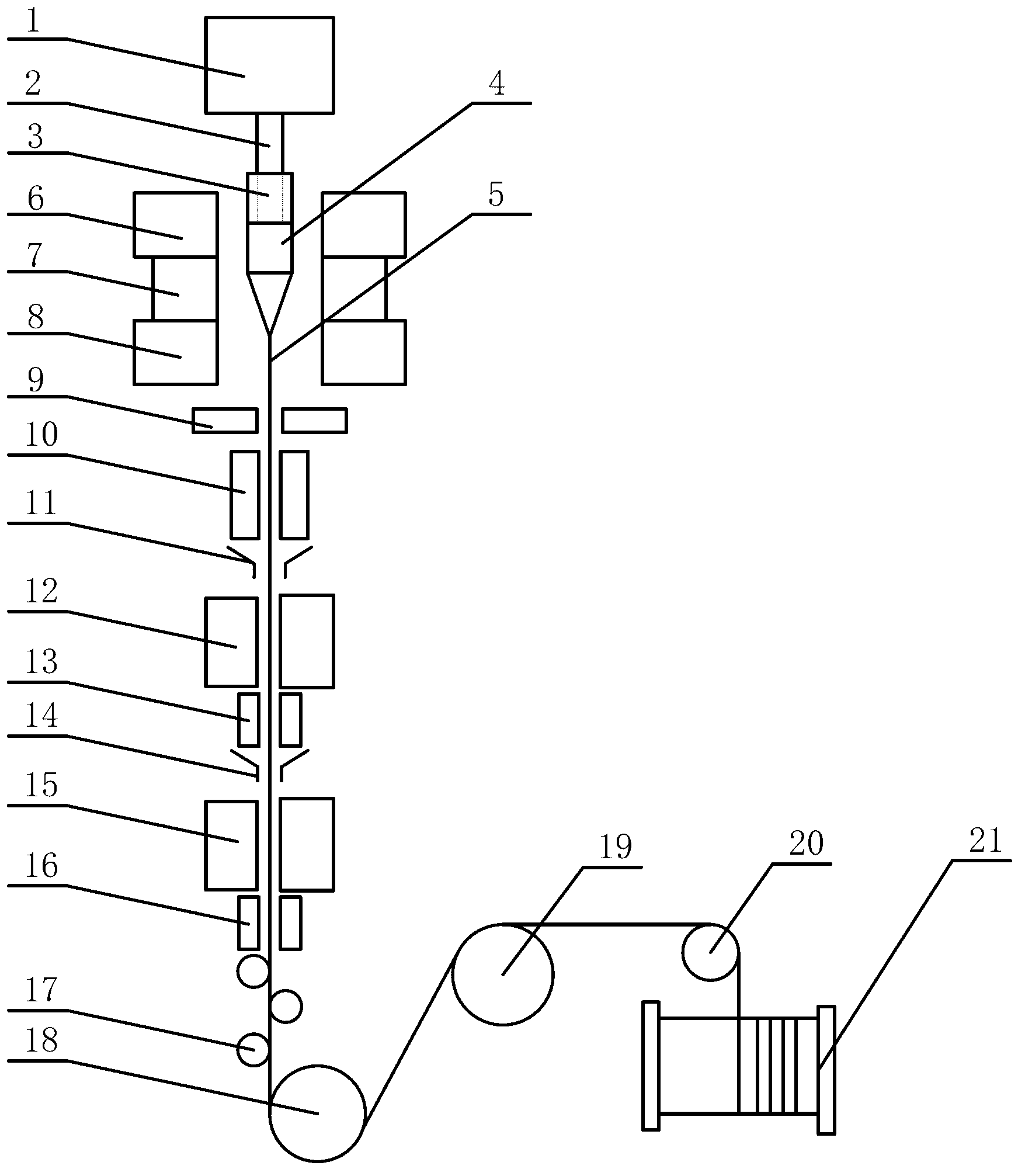

High-speed optical fiber drawing device and method

An optical fiber, high-speed technology, applied in the field of high-speed optical fiber drawing devices, can solve the problems of large variation in optical fiber diameter, strong optical fiber jitter, easy reduction of optical fiber warpage, etc., to achieve stable warpage, uniform stress distribution, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

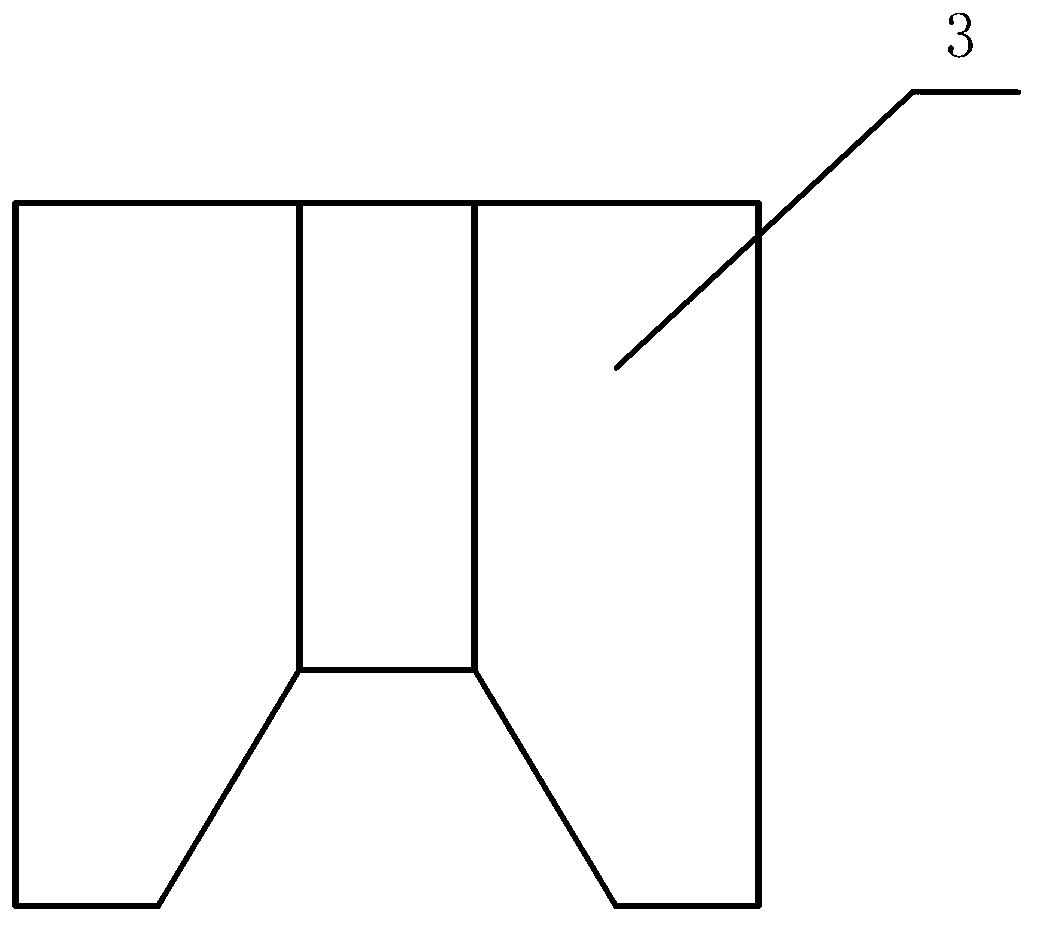

[0053] Embodiment 1: An optical fiber preform rod 4 with a diameter of 150 mm and a tail rod 2 with a diameter of 60 mm are selected, and the drawing speed is 2200 m / min.

[0054] Put the tail rod 2 on the top of the optical fiber preform 4 through the quartz collar 3, the inner diameter of the quartz collar 3 is 62 mm, and the outer diameter 21 is 150 mm; hang the top of the tail rod 2 on the bottom of the hanging rod mechanism 1. The optical fiber preform 4 and the tail rod 2 covered with the quartz collar 3 move at a speed of 2200m / min, passing through the preheating mechanism 6, the melting mechanism 7 and the annealing mechanism 8 in sequence, the value of a:b is 1.0, and the value of c:b The value is 1.0; the temperature of the preheating mechanism 6 is set at 1350°C, and the preheating mechanism 6 preheats the optical fiber preform 4 and tail rod 2; the temperature of the melting mechanism 7 is set at 1850°C to 2200°C, and the melting The mechanism 7 melts and draws the...

Embodiment 2

[0059] Embodiment 2: An optical fiber preform 4 with a diameter of 120 mm and a tail rod 2 with a diameter of 50 mm are selected, and the drawing speed is 2300 m / min.

[0060] Pass the tail rod 2 at the top of the optical fiber preform 4 through the quartz collar 3, the inner diameter of the quartz collar 3 is 52 mm, and the outer diameter 21 is 120 mm; hang the top of the tail rod 2 on the bottom of the hanging rod mechanism 1. The optical fiber preform 4 and the tail rod 2 covered with the quartz collar 3 move at a speed of 2300m / min, and pass through the preheating mechanism 6, the melting mechanism 7 and the annealing mechanism 8 in sequence, the value of a:b is 0.5, and the value of c:b The value is 0.5; the temperature of the preheating mechanism 6 is set at 1200°C, and the preheating mechanism 6 preheats the optical fiber preform 4 and tail rod 2; the temperature of the melting mechanism 7 is set at 1800°C to 2100°C, and the melting The mechanism 7 melts and draws the p...

Embodiment 3

[0065] Embodiment 3: An optical fiber preform 4 with a diameter of 150 mm and a tail rod 2 with a diameter of 60 mm are selected, and the drawing speed is 2400 m / min.

[0066] Put the tail rod 2 on the top of the optical fiber preform 4 through the quartz collar 3, the inner diameter of the quartz collar 3 is 62 mm, and the outer diameter 21 is 150 mm; hang the top of the tail rod 2 on the bottom of the hanging rod mechanism 1. The optical fiber preform 4 and the tail rod 2 covered with the quartz collar 3 move at a speed of 2400m / min, and pass through the preheating mechanism 6, the melting mechanism 7 and the annealing mechanism 8 in sequence, the value of a:b is 1.0, and the value of c:b The value is 1.0; the temperature of the preheating mechanism 6 is set at 1350°C, and the preheating mechanism 6 preheats the optical fiber preform 4 and tail rod 2; the temperature of the melting mechanism 7 is set at 1850°C to 2200°C, and the melting The mechanism 7 melts and draws the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com