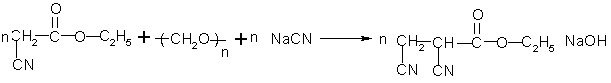

Synthesizing process of 2,3-dicyanoethylpropionate

A technology of ethyl dicyanopropionate and synthesis process, which is applied in the chemical industry, can solve the problems of affecting the yield of crude products, many side reactions, and high COD of wastewater, and achieves good extraction effect, less side reactions, and stable reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The synthetic technique of 2,3 ethyl dicyanopropionate comprises the following steps:

[0020] a. Start the motor to stir, suck in 800kg of dimethyl sulfoxide with vacuum, and open the cooling valve to cool down;

[0021] b. Inhale 200kg of ethyl cyanoacetate with vacuum;

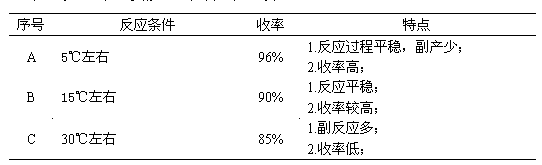

[0022] c. When the temperature drops to 4°C, put in 55kg of paraformaldehyde, then put in 95kg of sodium cyanide after 8 minutes, and keep the temperature at 4°C;

[0023] d. After feeding, keep for 1 hour, heat and azeotrope for 12 hours, add 30 kg of soda, and drop hydrochloric acid to make the pH value reach 3;

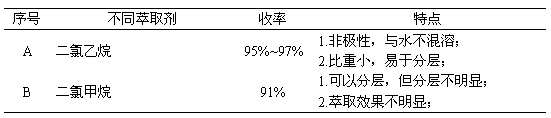

[0024] e. Quickly add 350 kg of dichloroethane extractant, stir for 18 minutes, stand still for 0.5 hours to separate layers, layer the upper layer of material and dichloroethane into the second reactor, and separate the lower layer of water and dimethyl sulfoxide Recycle;

[0025] f. Pump the layered material into the precipitation kettle, start stirring, and open the steam valve at t...

Embodiment 2

[0028] The synthetic technique of 2,3 ethyl dicyanopropionate comprises the following steps:

[0029] a. Start the motor to stir, suck in 830kg of dimethyl sulfoxide with vacuum, and open the cooling valve to cool down;

[0030] b. Inhale 210kg of ethyl cyanoacetate with vacuum;

[0031] c. When the temperature drops to 4°C, put in 58kg of paraformaldehyde, then put in 96kg of sodium cyanide after 9 minutes, and keep the temperature at 4°C;

[0032] d. After feeding, keep for 1 hour, heat and azeotrope for 12 hours, add 30 kg of soda, drop hydrochloric acid, so that the pH value reaches 3.5;

[0033] e. Quickly add 380 kg of dichloroethane extractant, stir for 19 minutes, stand still for 0.5 hours to separate layers, layer the upper layer of material and dichloroethane into the second reactor, and separate the lower layer of water and dimethyl sulfoxide Recycle;

[0034] f. Pump the layered material into the precipitation kettle, start stirring, and open the steam valve at ...

Embodiment 3

[0037] The synthetic technique of 2,3 ethyl dicyanopropionate comprises the following steps:

[0038] a. Start the motor to stir, suck in 850kg of dimethyl sulfoxide with vacuum, and open the cooling valve to cool down;

[0039] b. Inhale 210kg of ethyl cyanoacetate with vacuum;

[0040] c. When the temperature drops to 5°C, put in 60kg of paraformaldehyde, then put in 97kg of sodium cyanide after 10 minutes, and keep the temperature at 5°C;

[0041] d. After feeding, keep for 1 hour, heat and azeotrope for 12.5 hours, add 30 kg of soda, drop hydrochloric acid, so that the pH value reaches 3.5;

[0042] e. Quickly add 400kg of dichloroethane extractant, stir for 20 minutes, stand still for 0.5 hours to separate layers, layer the upper layer of material and dichloroethane into the second reaction kettle, and separate the lower layer of water and dimethyl sulfoxide Recycle;

[0043] f. Pump the layered material into the precipitation kettle, start stirring, and open the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com