Diamond abrasive and electroplated diamond tool

A diamond and abrasive technology, applied in the field of diamond abrasives and electroplating diamond tools, can solve problems such as affecting cutting ability, diamond abrasive falling off, diamond abrasive clumping, etc., and achieve the effect of improving operation accuracy and reducing the probability of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

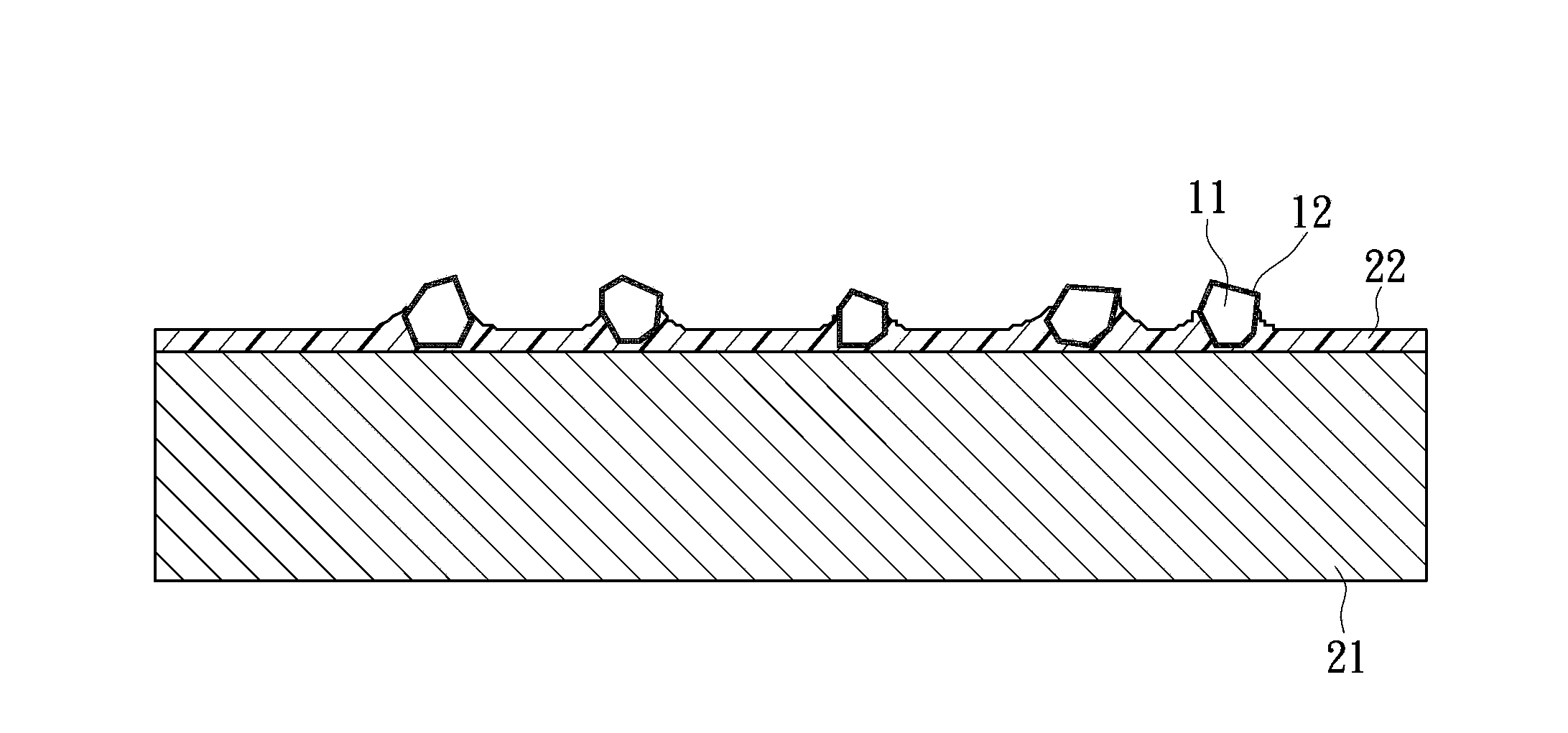

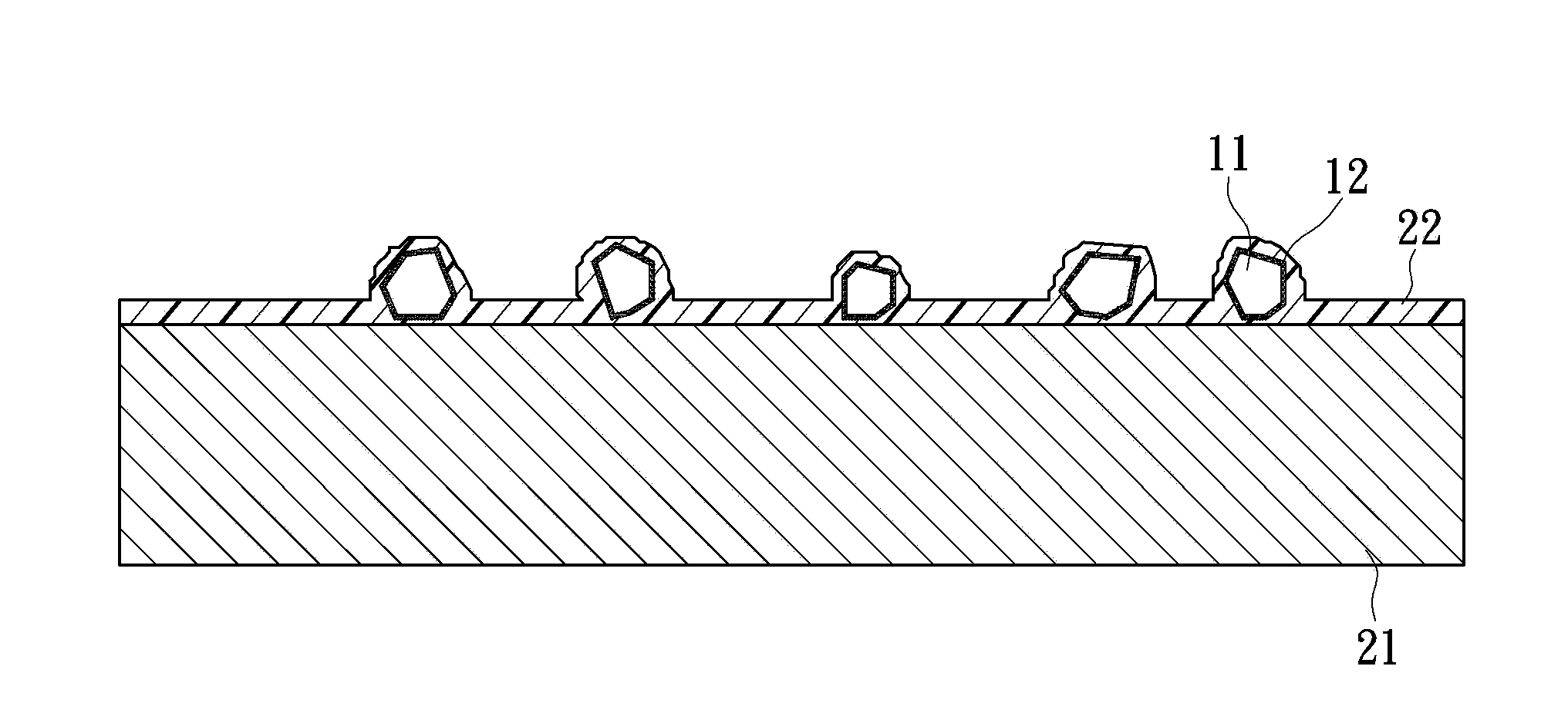

[0034] The present invention is to provide a kind of diamond abrasive, after its surface is modified, the surface of the diamond abrasive has micro-conductivity, so that in the process of the diamond abrasive being electroplated and attached to the surface of the tool, the electroplated metal can grow along the surface of the diamond abrasive, improving The adhesion of diamond abrasives to the tool surface while maintaining the surface precision of the diamond tool.

[0035] The present invention provides a kind of surface modification mode of diamond abrasive, and its steps are as follows:

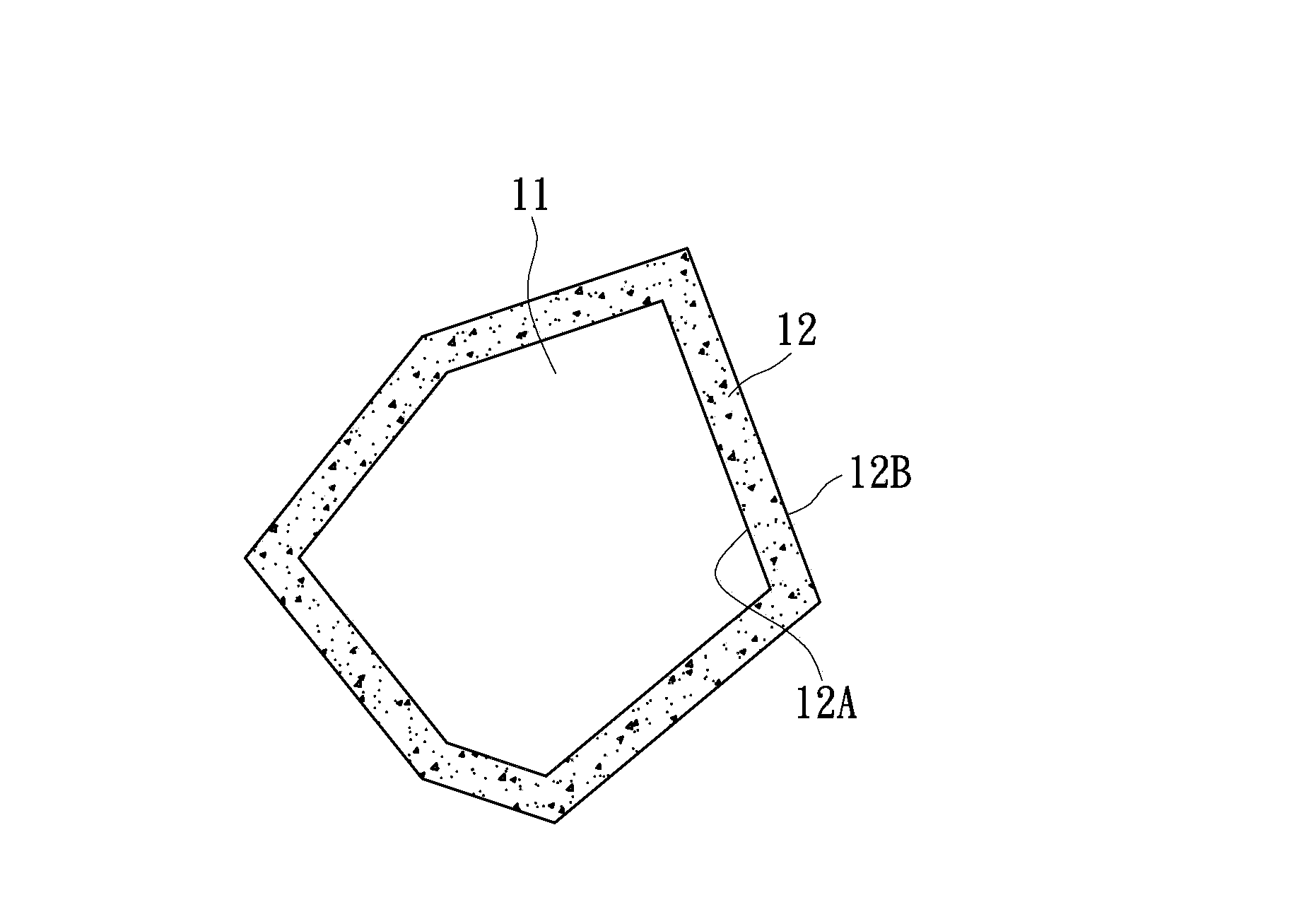

[0036] Step 1: If figure 1 , providing diamond abrasives 11 . In this specific embodiment, the diamond abrasive 11 is a natural diamond particle or an artificial diamond particle of a micron (micro) level or a nanometer (nano) level, but it is not limited thereto. Preferably, the average particle size of the selected diamond abrasive 11 is The diameter ranges from about 1 micrometer (μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com