Tannase high-producing strain and preparation method thereof

A high-yield strain and tannase technology, applied in the field of microorganisms, can solve the problem of low production efficiency of tannase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

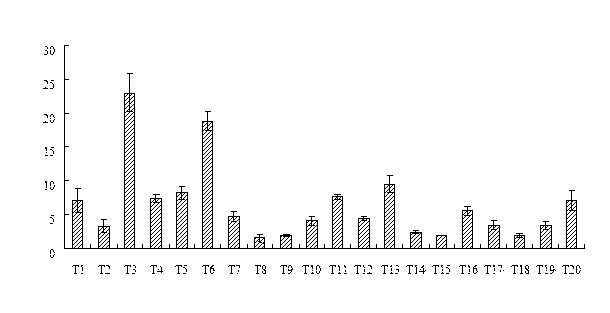

[0037] A high-yielding tannase strain, named T3-5-1, was identified as Aspergillus niger ( Aspergilluse niger ), the preservation number is CGMCC No.7423, the preservation time: April 7, 2013, and the preservation unit: General Microorganism Center (CGMCC) of China Committee for the Collection of Microorganisms.

[0038] T3-5-1 tannase high-yielding bacterial strain is obtained by screening and preparing in the following steps:

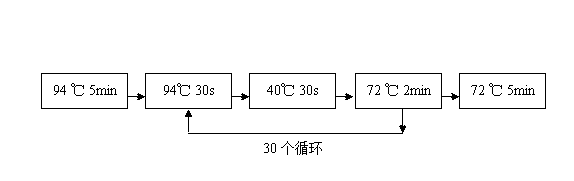

[0039] 1. Acquisition and preliminary screening of tannase-producing strains. Pick 10 g of rotten Chinese gallnuts and add 90 mL of sterile water, shake well, that is 10 -1 solution, serially diluted to 10 -10 , each gradient was coated with 3 plates on the screening medium, cultured at 30 °C for 48 h, and the single colonies with larger colonies and larger hydrolysis circles on the plates were picked and stored on the slant of the test tube PDA. Wherein the screening medium consists of: potassium dihydrogen phosphate 4.38g, ammonium sulfate 8.76g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com