Flexible bearing for symmetrical spiral crossed reed

A flexible bearing and reed technology, applied in the direction of flexible bearings, rotating bearings, bearings, etc., can solve the problems of difficult integrated processing of flexible bearings, limit the practical application of flexible bearings, lack of other problems, and simplify machine tool program design and processing. Steps, Overcome Warpage, Improve Processing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

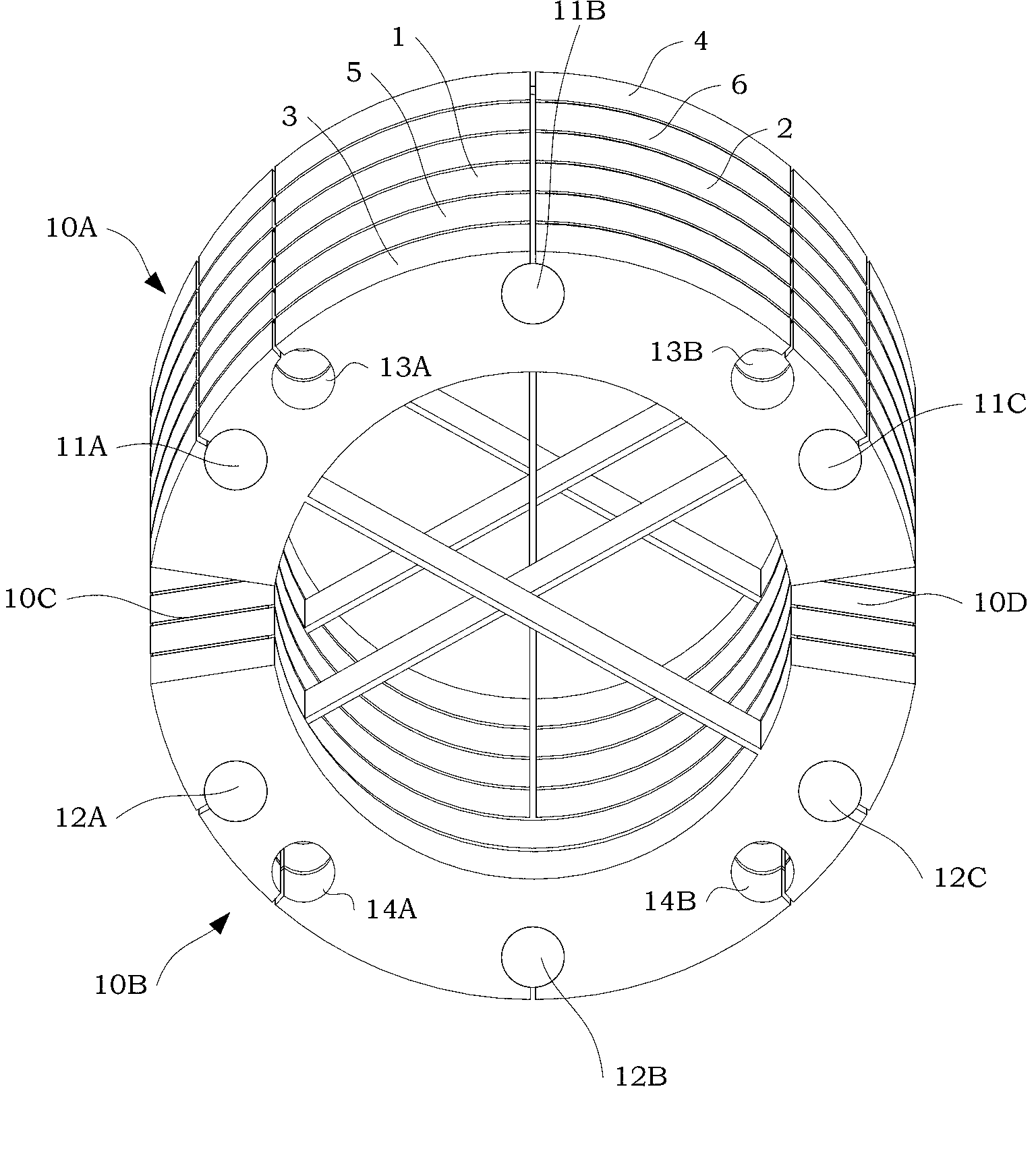

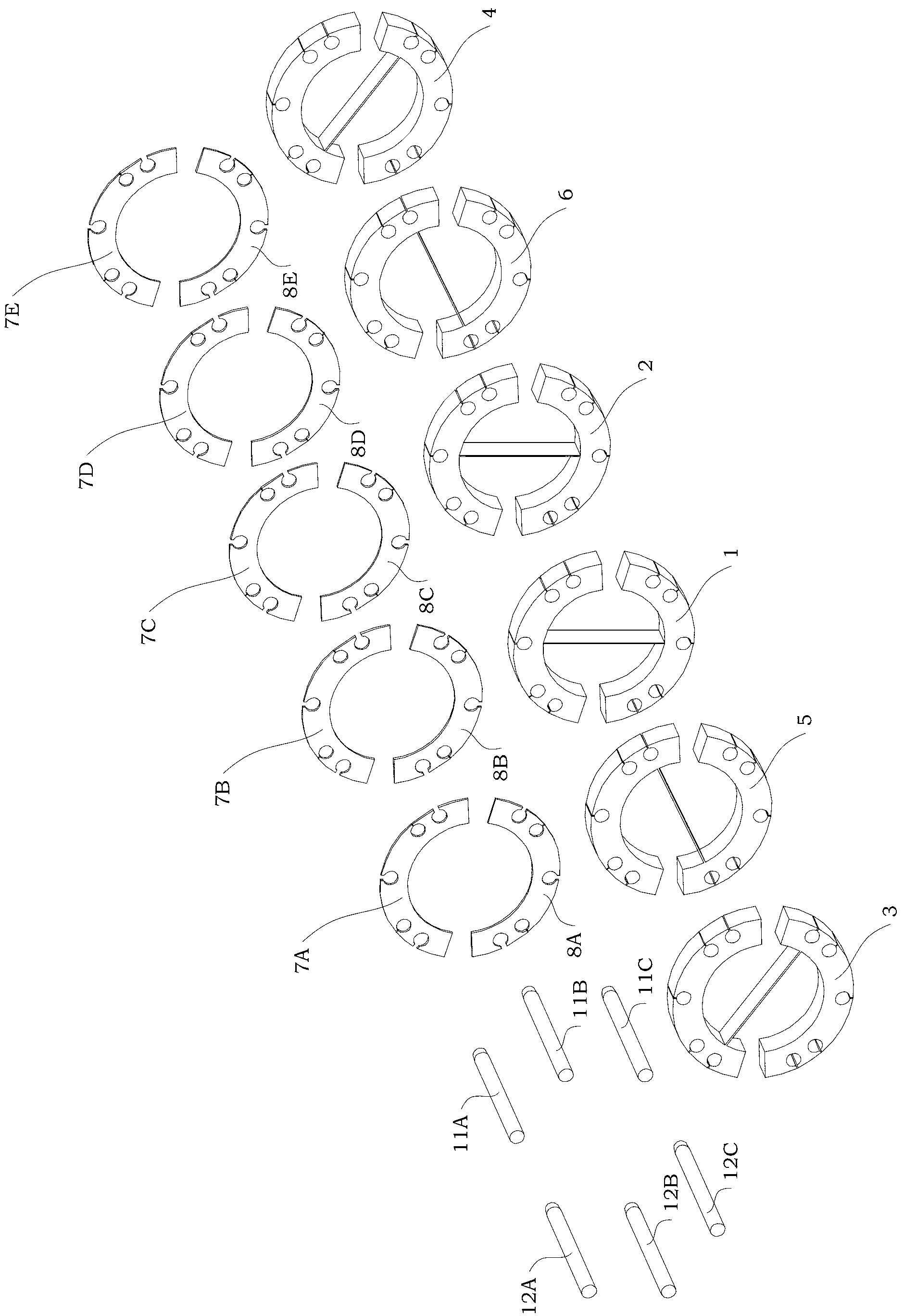

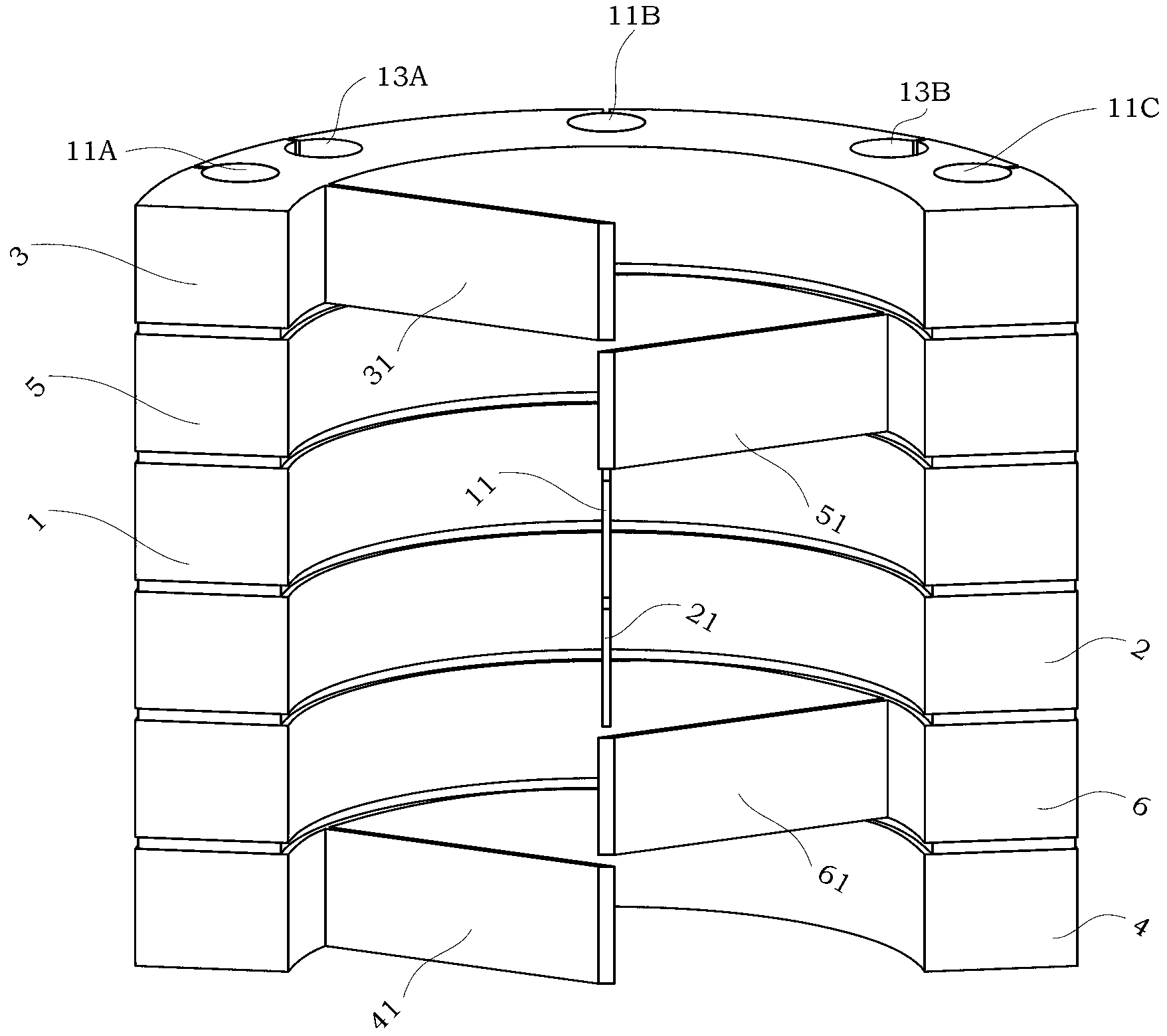

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0051] See figure 1 , Figure 1A , Figure 1B As shown, a symmetrical spiral cross-reed flexible bearing with six reed units of the present invention includes an upper middle single reed ring body 1, a lower middle single reed ring body 2, an upper end single reed ring body The body 3, the lower end single reed ring body 4, the upper transition single reed ring body 5, the lower transition single reed ring body 6, and a plurality of spacers and a plurality of cylindrical pins; wherein, the single reed ring body and The gasket is a laminated assembly.

[0052] The gasket refers to AA gasket 7A, AB gasket 7B, AC gasket 7C, AD gasket 7D, AE gasket 7E, BA gasket 8A, BB gasket 8B, BC gasket 8C, BD gasket 8D And BE gasket 8E; In the present invention, the structure of the gasket is the same.

[0053] The cylindrical pins refer to AA cylindrical pins 11A, AB cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com