Radiating method of aluminum electrolytic capacitor bunch of power unit of controller for electric vehicle

A technology for electric vehicle controllers and aluminum electrolytic capacitors, applied in electrolytic capacitors, capacitors, output power conversion devices, etc., can solve the problem of no heat dissipation channels, difficult assembly process of motor drive controllers, and reduced operating reliability of controllers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

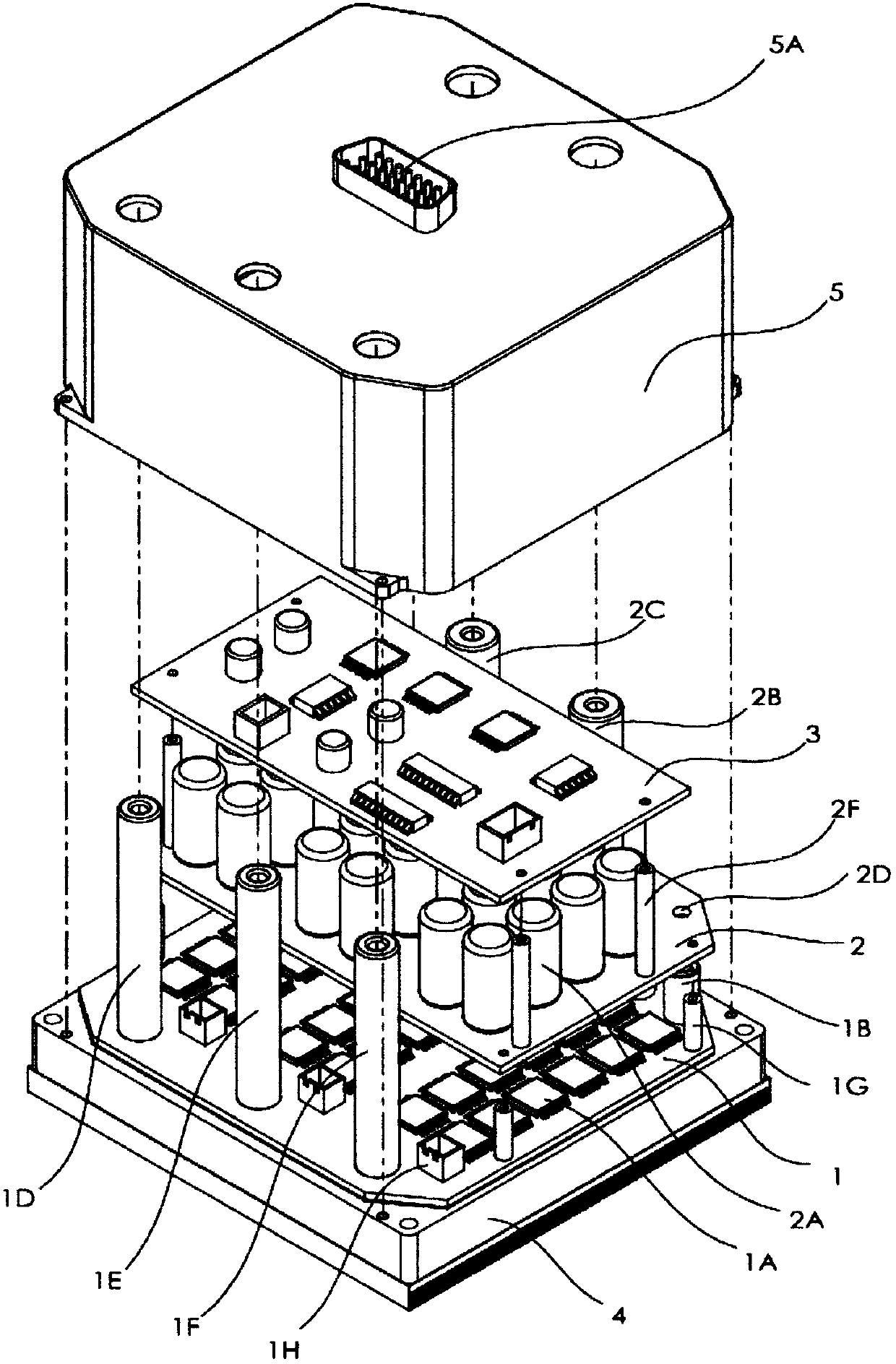

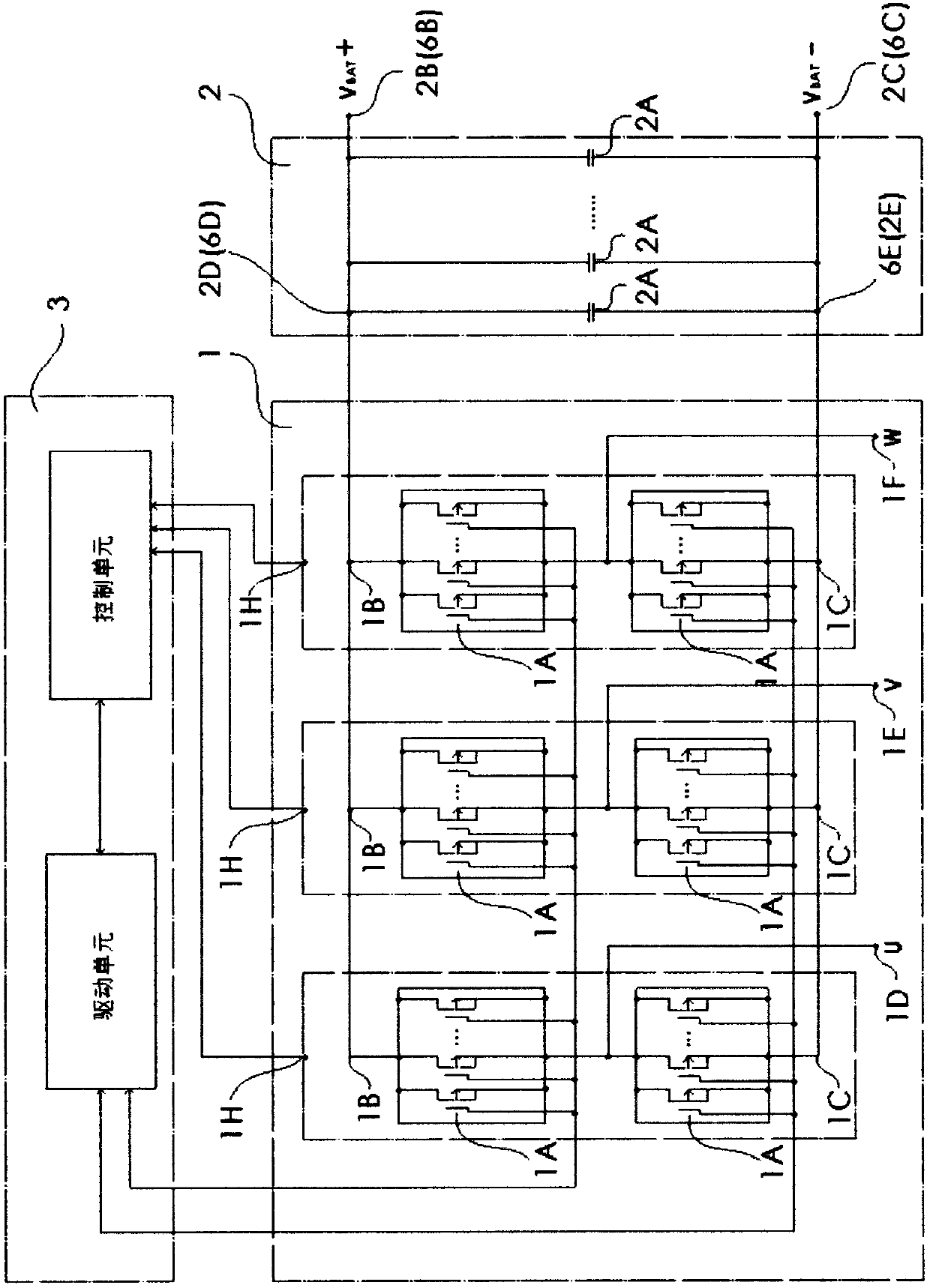

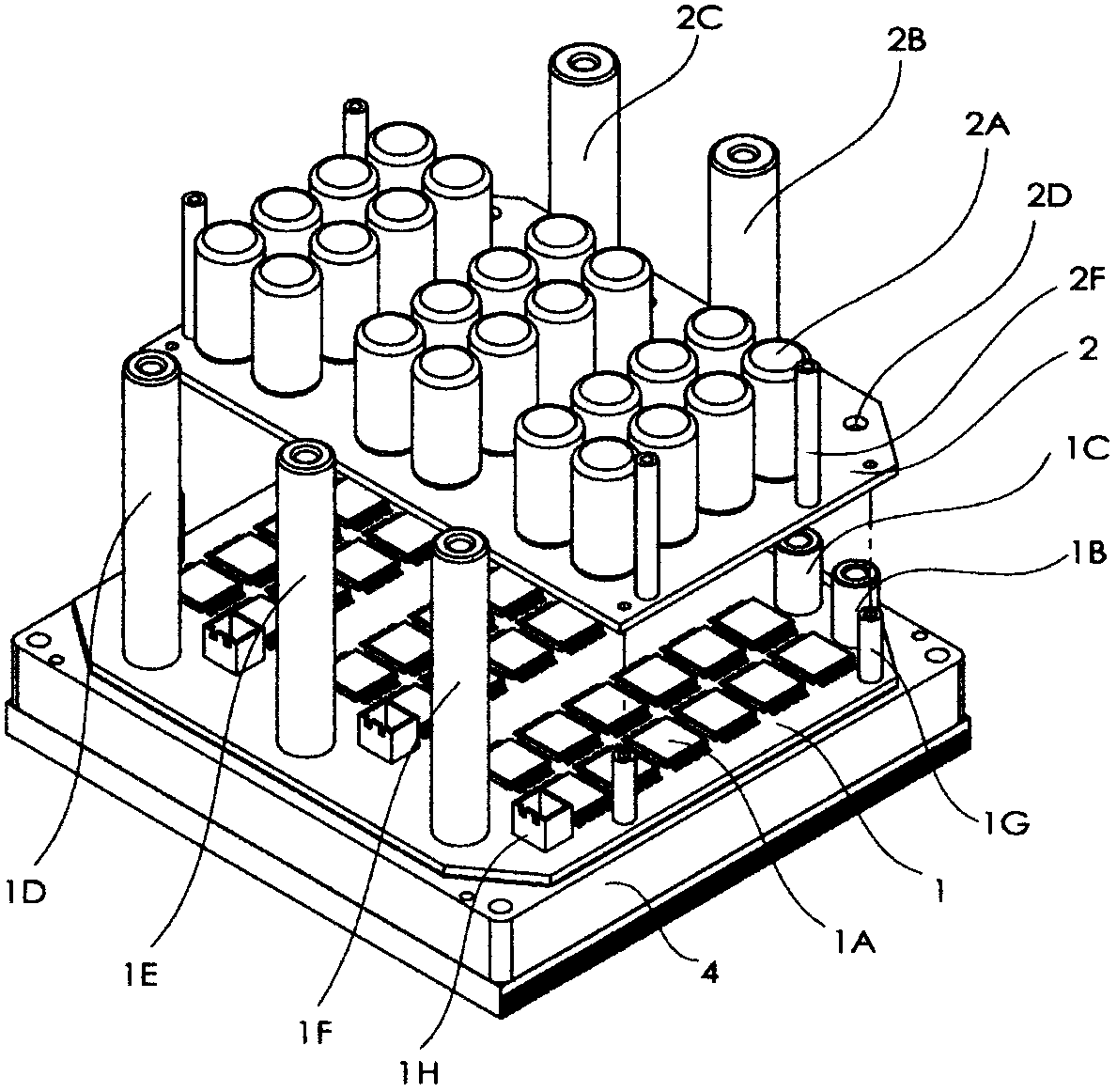

[0045] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0046] The aluminum electrolytic capacitors 2A are connected in parallel to form a capacitor module by using a conductive busbar structure, and are enclosed in a rectangular box-shaped casing to form a clustered aluminum electrolytic capacitor module block 6 . The upper part of the bundled square aluminum electrolytic capacitor module 6 has cylindrical terminals 6B and 6C for connecting wires with the battery; the bundled square aluminum electrolytic capacitor module 6 has three sets of positive lead-out terminals 6D and Negative lead-out terminal 6E is respectively connected and installed with three sets of positive input terminal 1B and negative input terminal 1C of power MOSFET module 1 mounted on power MOSFET (1A) aluminum substrate, and the box body 6 shell has a lower opening side plane as a heat dissipation surface 6A , fit with the radiator 4 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com