Hermetically-sealed chamber

A technology of sealing cavity and sealing groove, which is applied to the sealing of engines, pressure vessels, engine components, etc. It can solve the problems that the inside of the container cannot maintain vacuum, leakage, and sealing parts are difficult to seal, so as to reduce material costs and improve sealing The effect of stability and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

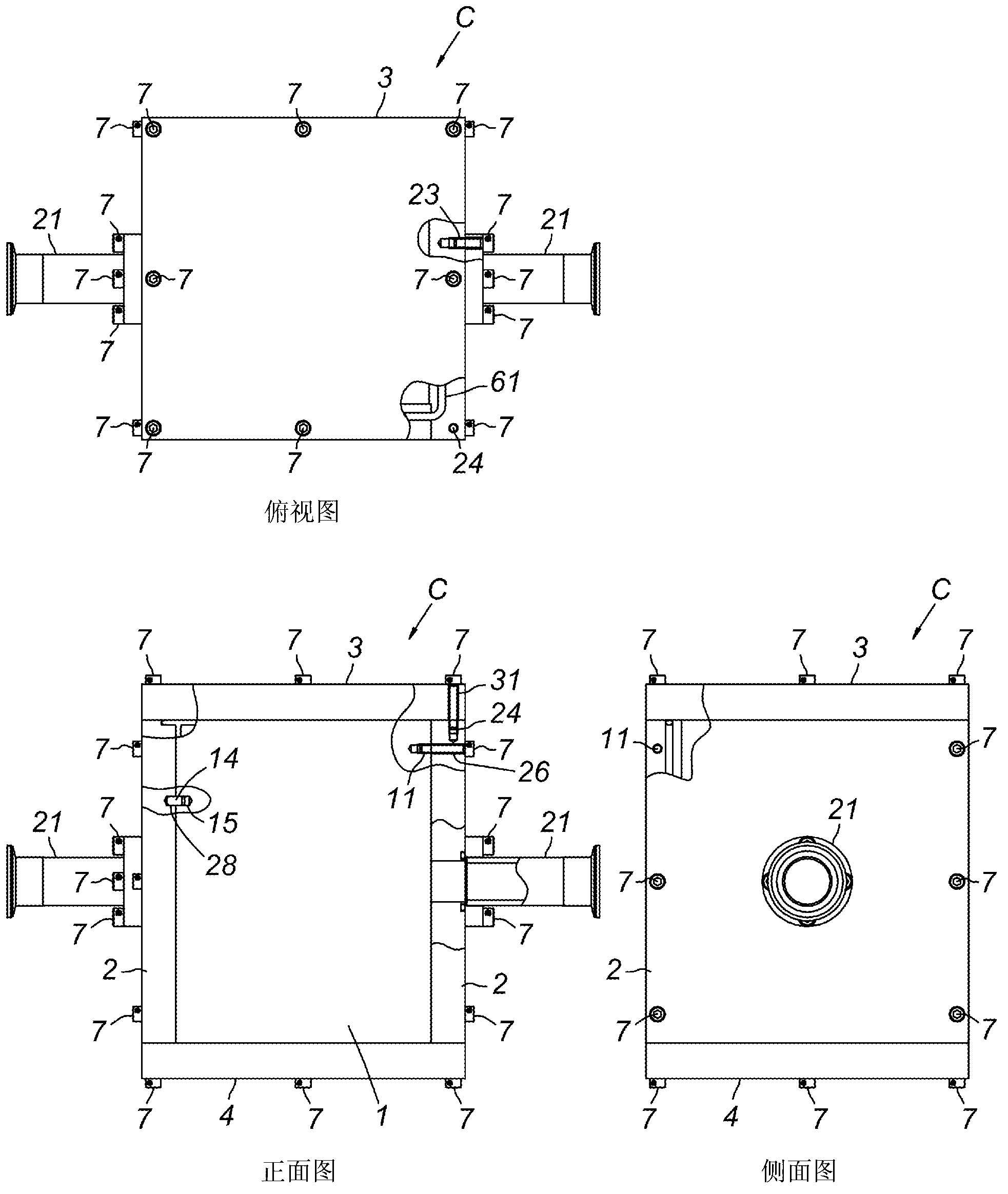

[0041] Such as figure 1 As shown, the sealed chamber C of the present invention is an assembled container that uses a plurality of plates 1, 2, 3, 4, sealing members 5, and bolts 7. For example, in a semiconductor manufacturing device, the inside is vacuumed. It can be used as a vacuum chamber for film formation and etching of semiconductor wafers.

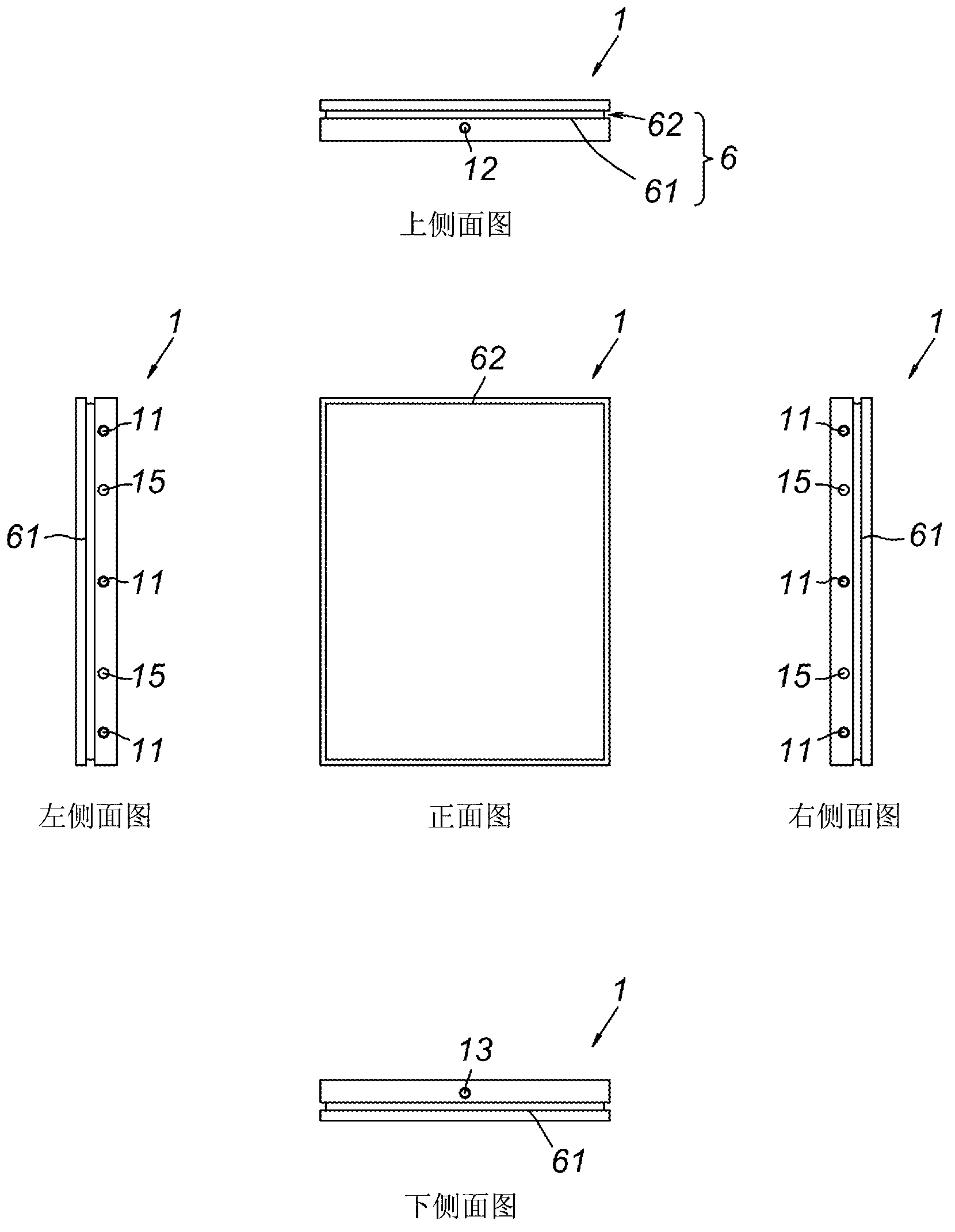

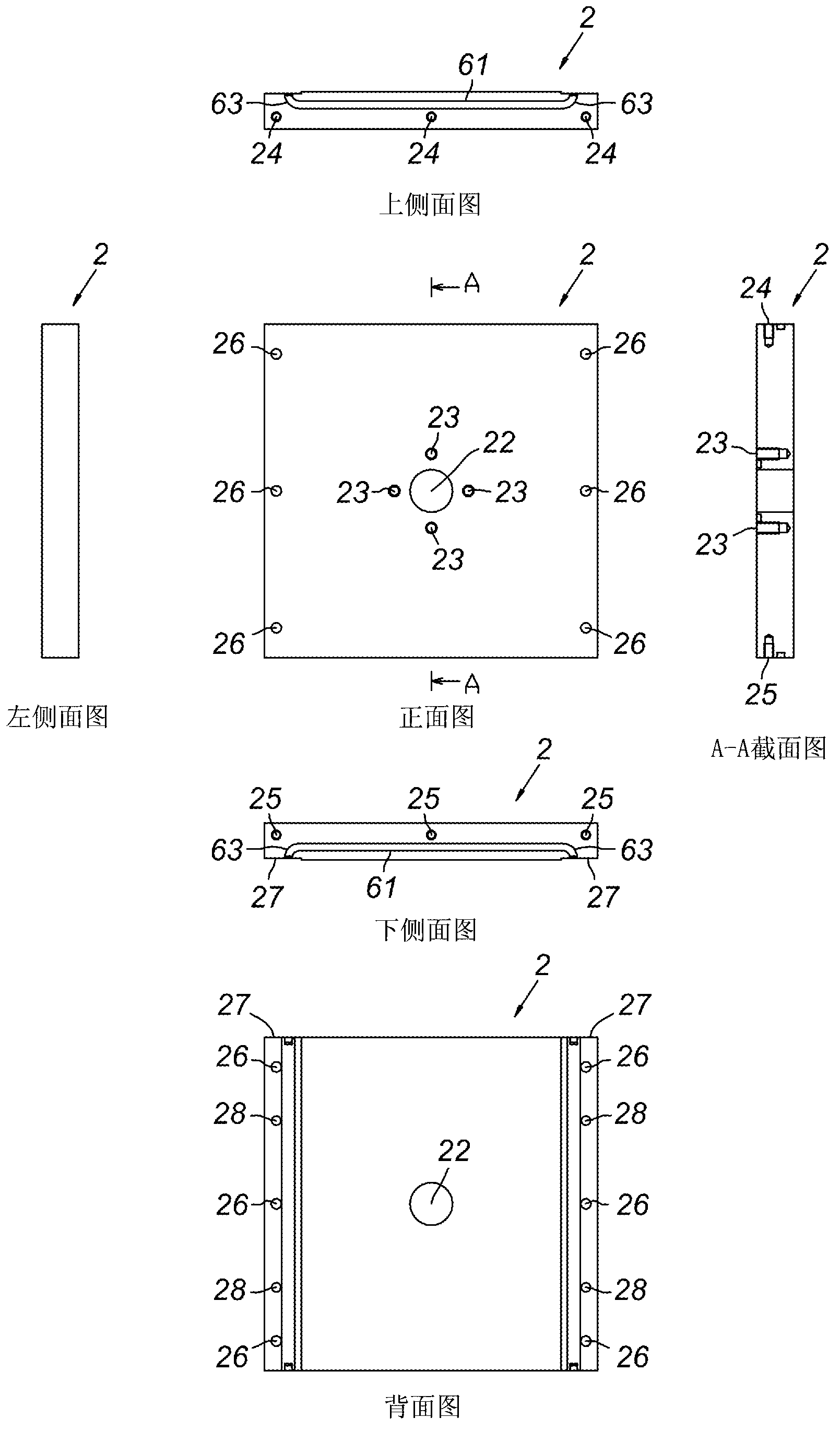

[0042] In this embodiment, the sealed chamber C forms a planar quadrilateral formwork 8 by fixing two side plates 1, 1 facing each other and two side plates 2, 2 with exhaust ports by bolts 7, A top plate 3 is provided on the upper opening surface of the formwork 8, and a bottom plate 4 is provided on the lower opening surface, and then fixed with bolts 7 to form a rectangular parallelepiped hollow container with a sealed space inside. And, the joint surface between the formwork 8 and the top plate 3, the joint surface be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com