Wearable flexible sensor and making method thereof

A flexible sensor and sensor layer technology, applied in the direction of sensors, chemical instruments and methods, diagnosis, etc., can solve the problems of difficult fabrication and processing of fabric sensors, large surface fluctuations of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

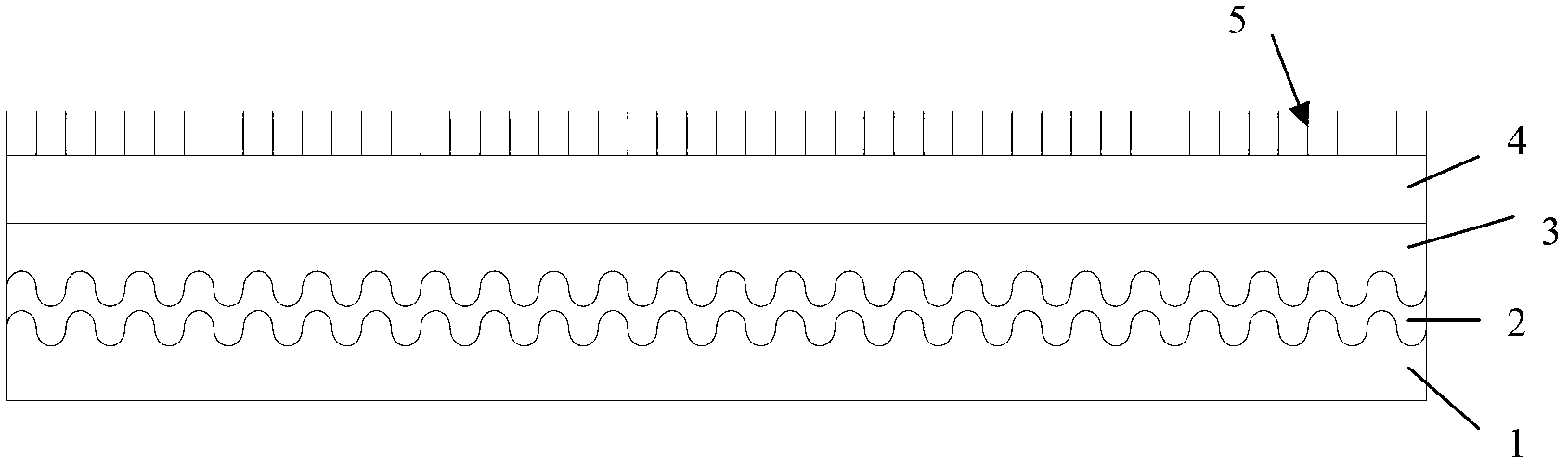

[0030] The present invention also provides a preparation method of a wearable flexible sensor, which is characterized in that, comprising the following steps:

[0031] (1) Cloth cleaning. Soak the cloth with a mixed solution of alcohol and acetone with a volume ratio of 1:1, and ultrasonically clean it in an ultrasonic generator for 5-10 minutes. Remove the fabric and blow dry with an air gun.

[0032] (2) Apply the barrier layer. Evenly coat the slurry with a solid powder content of 15%-30% on the surface of the cloth treated in step (1), spin coating at a speed of 500-2000 rpm for 10-30 seconds, and bake .

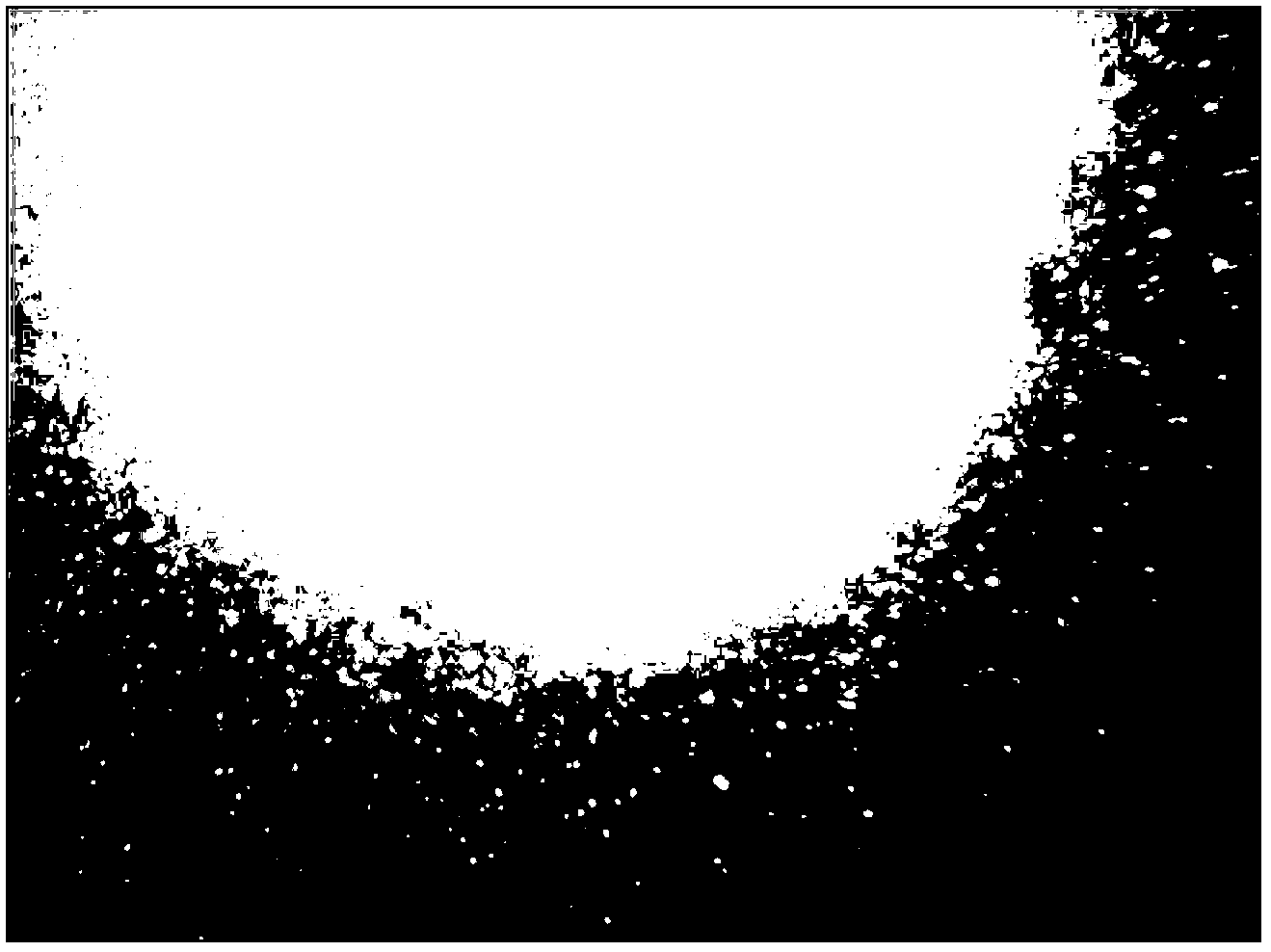

[0033] (3) Apply the gap filler. Drop the flexible colloidal solution on the substrate in step (2) for uniform spin coating, the spin coating speed is 500-1000 rpm, and the time is 10-30 seconds. The spin-coated samples were baked in an oven. After the baking, the temperature is naturally cooled to room temperature; the spin coating and annealing are repeated repea...

Embodiment 1

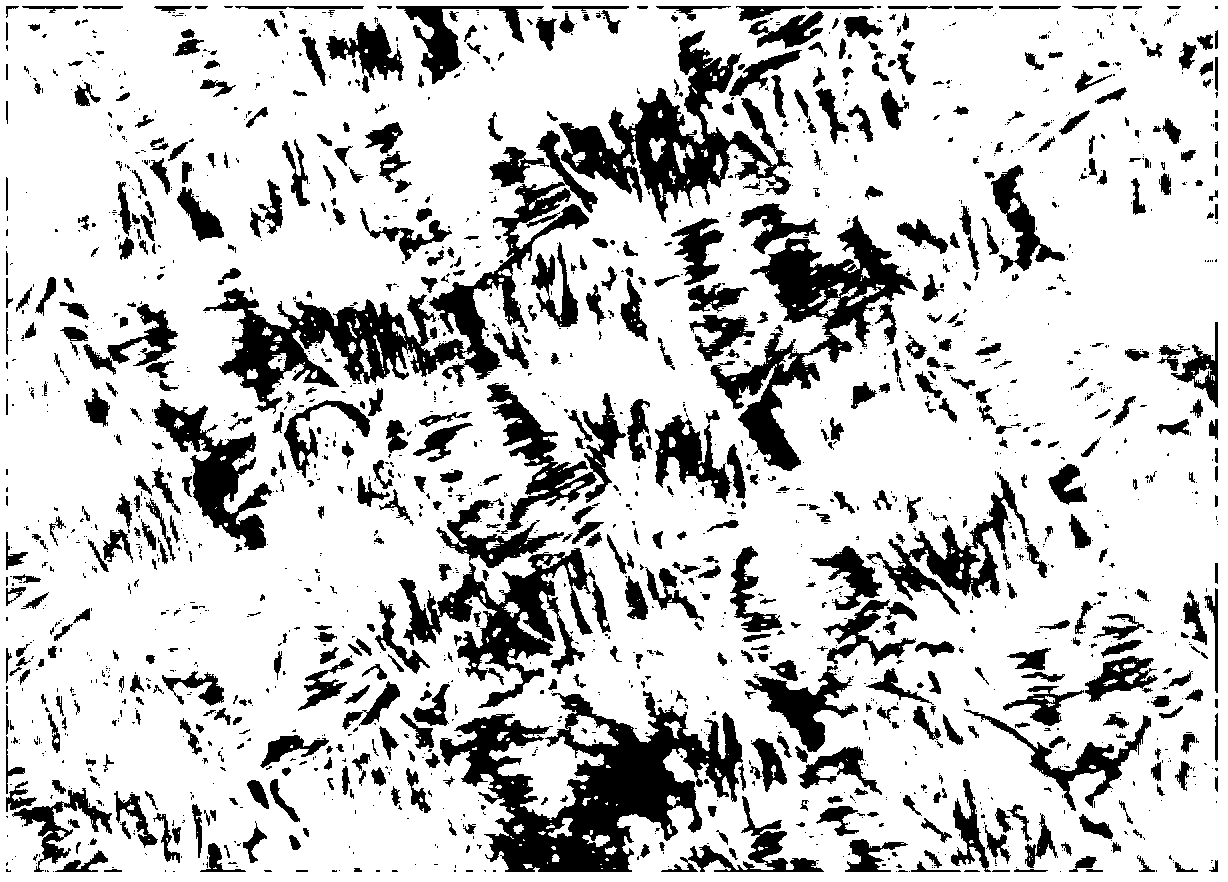

[0040] Arrange cotton with a size of 20mm×20mm in a mixed solution of alcohol and acetone with a volume ratio of 1:1 for ultrasonic cleaning for 10 minutes, take out the cloth and blow dry it with an air gun. Lay the cleaned cotton cloth on the middle of the 25mm×25mm Si sheet, and place it on the glue-spinning machine. The silver paste with a solid powder content of 15% was dropped on the surface of the cloth, and spin-coated at a speed of 1000 rpm for 20 seconds. Remove the sample from the Si sheet, remove the tape on the back of the cloth, and bake the sample in an oven at 150°C for 30 minutes. Spread the cloth coated with barrier layer on the middle of the Si sheet again, and place it on the gluing machine. AZ5214 photoresist was dropped on the surface of the barrier layer and rotated at 600 rpm for 20 seconds. The samples were baked in an oven at 100°C for 5 minutes. Repeat the spin coating and annealing process 7 times to get a relatively flat surface. Put the treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com