Light and heat insulation roof board or floor slab

A technology for thermal insulation roof panels and thermal insulation panels, which is applied to floors, roofs, roof coverings, etc., can solve the problems of aging, high cost, and increase the weight of buildings, and achieve the effects of convenient installation, convenient construction and installation, and increased safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

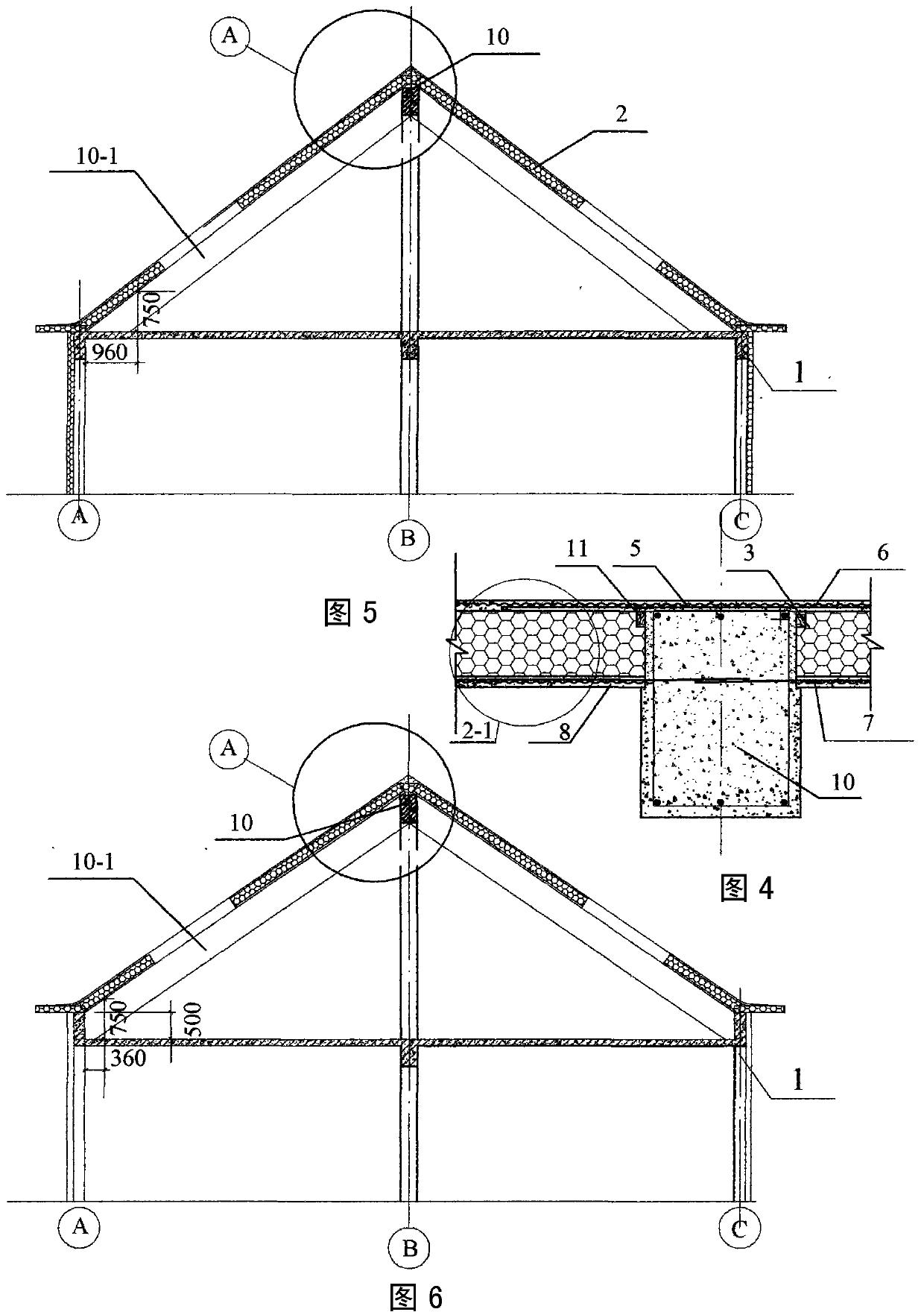

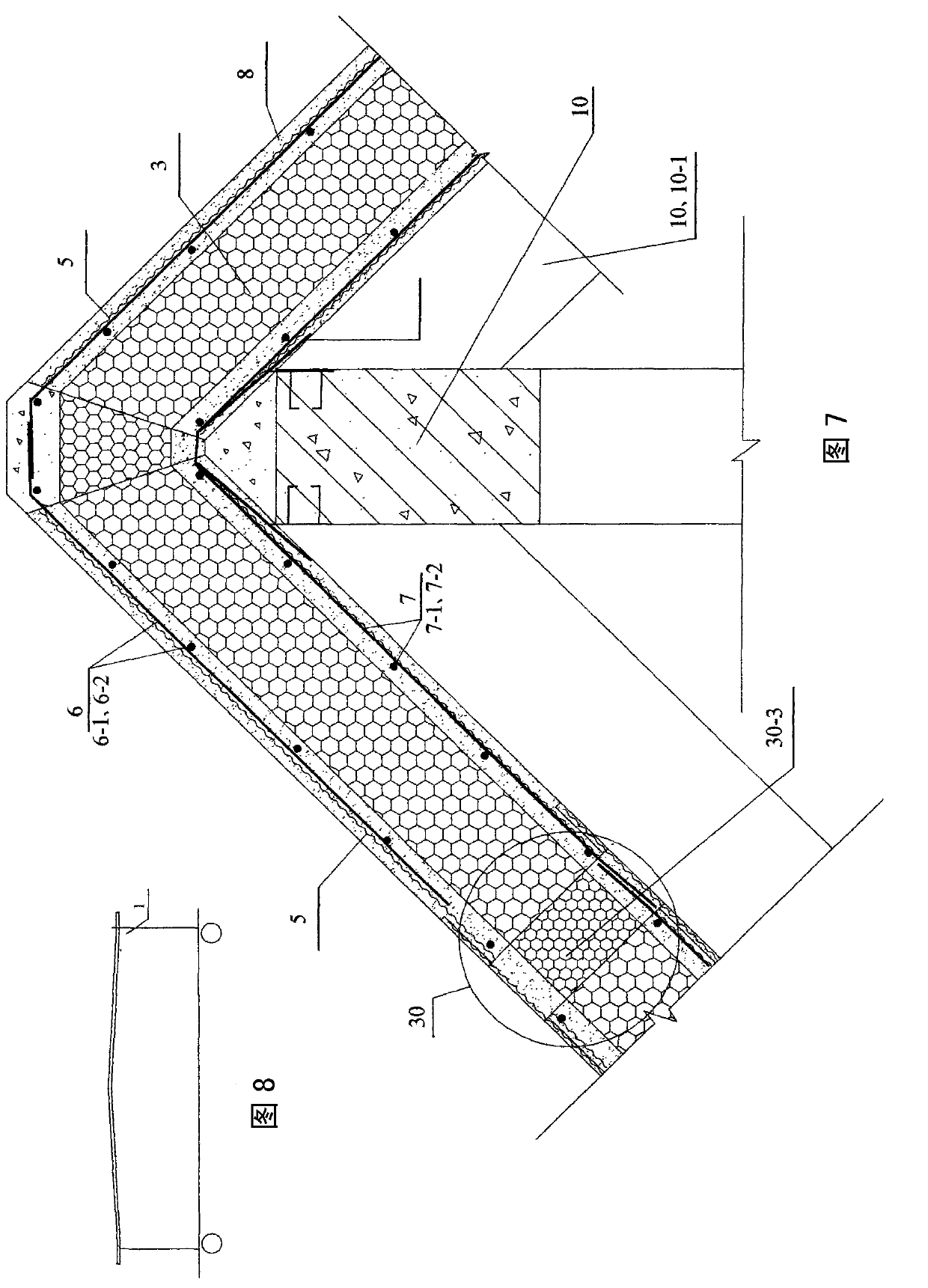

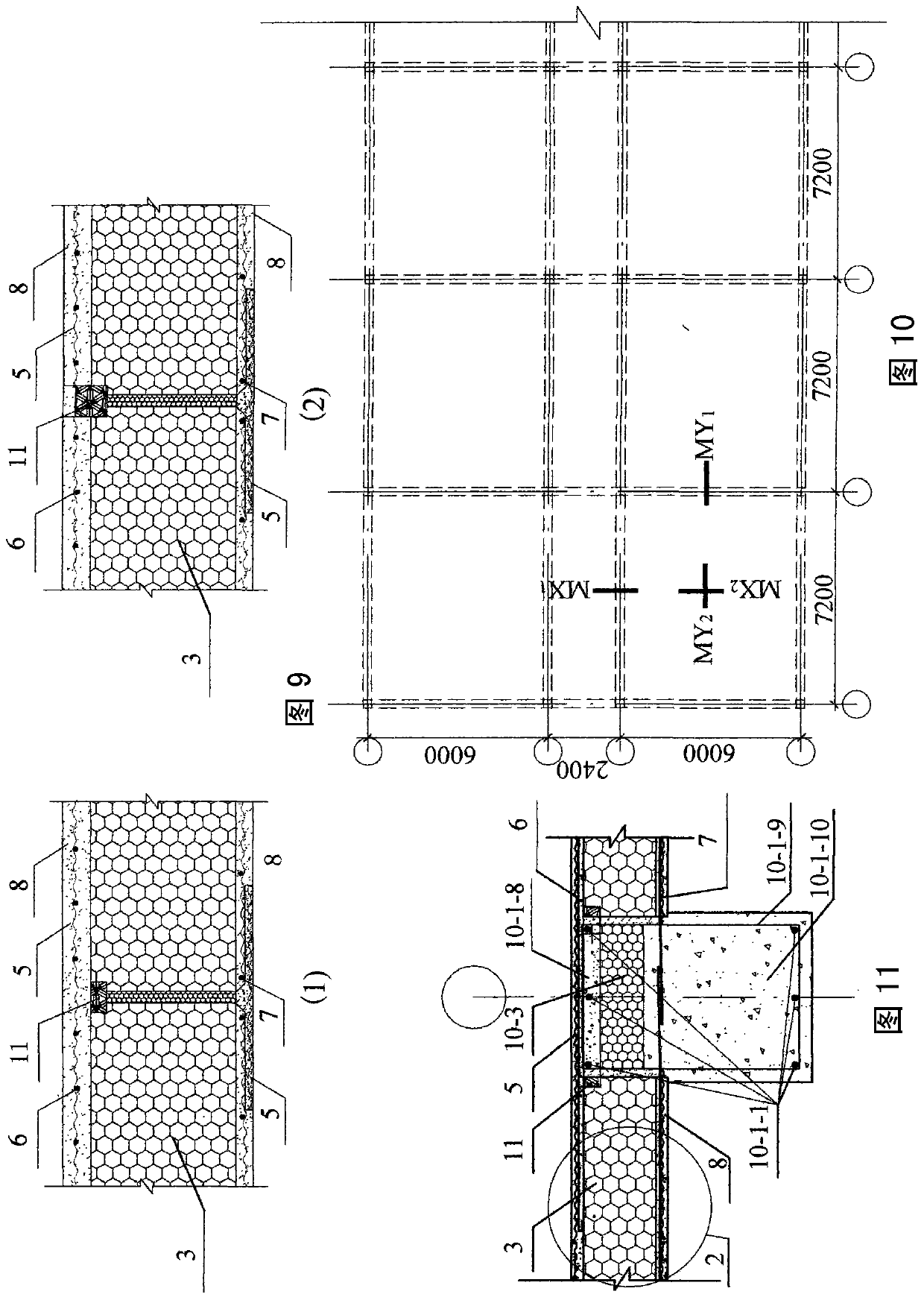

[0094] Implementation mode one: see Figure 1 to Figure 17 , a light-duty thermal insulation roof panel or floor slab of this embodiment is an assembled integral lightweight thermal insulation roof panel or floor panel formed by installing a prefabricated lightweight thermal insulation board 2-1; it is composed of a prefabricated light thermal insulation board 2-1, The external wall load-bearing member 1 and the intermediate load-bearing member 10 are composed; the external wall load-bearing member 1 and the intermediate load-bearing member 10 are the supports of the prefabricated light insulation board 2-1 (the prefabricated light insulation board can also be a cantilever board, that is, only The load-bearing member 1 of the outer wall is a bearing); the load-bearing member 1 of the outer wall is a load-bearing outer wall, a concrete beam or a steel beam; the intermediate load-bearing member 10 is a load-bearing inner wall, a concrete beam or a steel beam;

[0095] There is a...

Embodiment approach 2

[0119] Implementation mode two: see figure 1 The difference between this embodiment and Embodiment 1 is that this embodiment adds anchor bolts 20 or / and connecting iron parts 20-1, and uses anchor bolts 20 or / and connecting iron parts 20-1 to connect the prefabricated light insulation board 2 -1 is fixed with the load-bearing component 1 of the outer wall and the load-bearing component 10 in the middle.

[0120] When the roof slope is relatively large, in order to ensure the safety of the installed mid-slope roof, it is convenient to fix the prefabricated light insulation board 2-1 with anchor bolts. When the insulation layer is a non-alkaline insulation material, high-strength polyethylene plastic anchor bolts have good durability and can be installed like nails. It can reach 1.4KN, and plastic anchor bolts with larger tensile values can also be produced according to engineering needs, without increasing heat transfer. It not only provides convenience for construction an...

Embodiment approach 3

[0123] Implementation mode three: see Figure 11 The difference between this embodiment and Embodiment 1 or 2 is that the support of the prefabricated light insulation board 2-1 in this embodiment is a light insulation beam 10-1; the light insulation beam 10-1 is provided with longitudinal reinforcement 10-1-1, thermal insulation layer 10-1-3, upper protective layer 10-1-8, steel hoop 10-1-9 and concrete 10-1-10; end of longitudinal reinforcement 10-1-1 and outer wall The load-bearing member 1, the intermediate load-bearing member 10 or the column connection with the main structure of the building; the thermal insulation layer 10-1-3 is polymer thermal insulation material, foam concrete, paper honeycomb board, plant straw or thermal insulation mortar board, and the thermal insulation layer 10-1-3 1-3 and the insulation layer 3 can be the same material or different materials, and the gap between the insulation layer 3 of the prefabricated light insulation board 2-1 and the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com