Intelligent detection and yield optimization method for HDPE (high density polyethylene) cascade polymerization reaction course

A cascade polymerization, high-density polyethylene technology, applied in the field of intelligent detection and yield optimization of high-density polyethylene cascade polymerization process, can solve problems such as reducing the fitting accuracy of a single ELM neural network, and achieve fast online The effect of fast detection, learning speed and few adjustable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

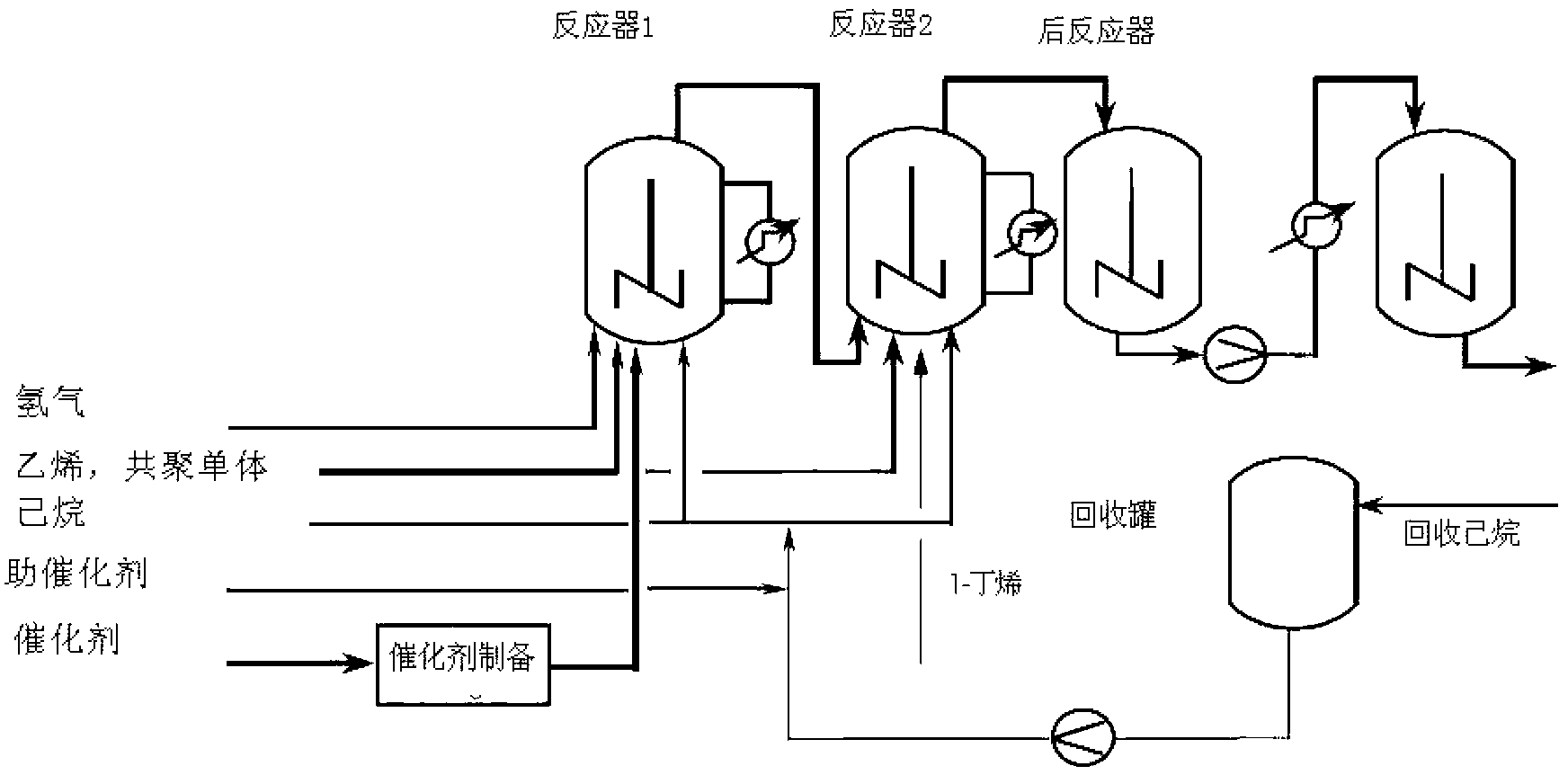

[0023] Such as figure 1 Shown is the flow chart of HDPE cascade polymerization reaction. The reaction process is mainly composed of two slurry reactors. Ethylene is introduced in a gaseous state, dissolved in a solvent and diffused to the surface of catalyst particles. The reaction is accelerated by stirring to form polyethylene particles, which are then dried with a diluent to produce high-density polyethylene. product. Due to its low price and good performance, the HDPE products produced have now become the third most demanded polyolefin variety in the world, and are widely used in film, blow molding, pipes, etc. Among them, the specifications of polyethylene products in the industry are mainly distinguished according to the melt index of the second reactor. Due to the lack of online measurement means, it takes two hours for a laboratory analysis of the melt index. Obviously, there is a big lag in this frequency. When it is found that the quality of the resin is not up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com