Sodium-ion battery cathode material and preparation method thereof

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost and high energy consumption, and achieve the effects of low cost, simple preparation process, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Commercial sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 *10H 2 O) and sodium chloride are weighed according to the molar ratio of 0.5:0.5, wherein the quality of sodium ferrocyanide is 1.21g, and the quality of sodium chloride is 0.1461g, and they are dissolved in 10mL of deionized water to form a mixed solution . Pipette 400mL of ethanol into the beaker, add a magnetic stirrer, place the beaker containing ethanol on a temperature-controllable and speed-adjustable magnetic stirrer, set the temperature to 20°C, and adjust the speed to 400r / min. The mixed solution was added to the stirring ethanol solution at a rate of 15 drops / min through a speed-adjustable peristaltic pump to obtain a yellowish precipitate. The precipitate was placed in a constant temperature vacuum drying oven at 100° C. for 8 hours in vacuum to obtain sodium ferrocyanide-sodium chloride solid solution powder with a particle diameter of about 50 nm. The solid solution powder, the conductive agent...

Embodiment 2

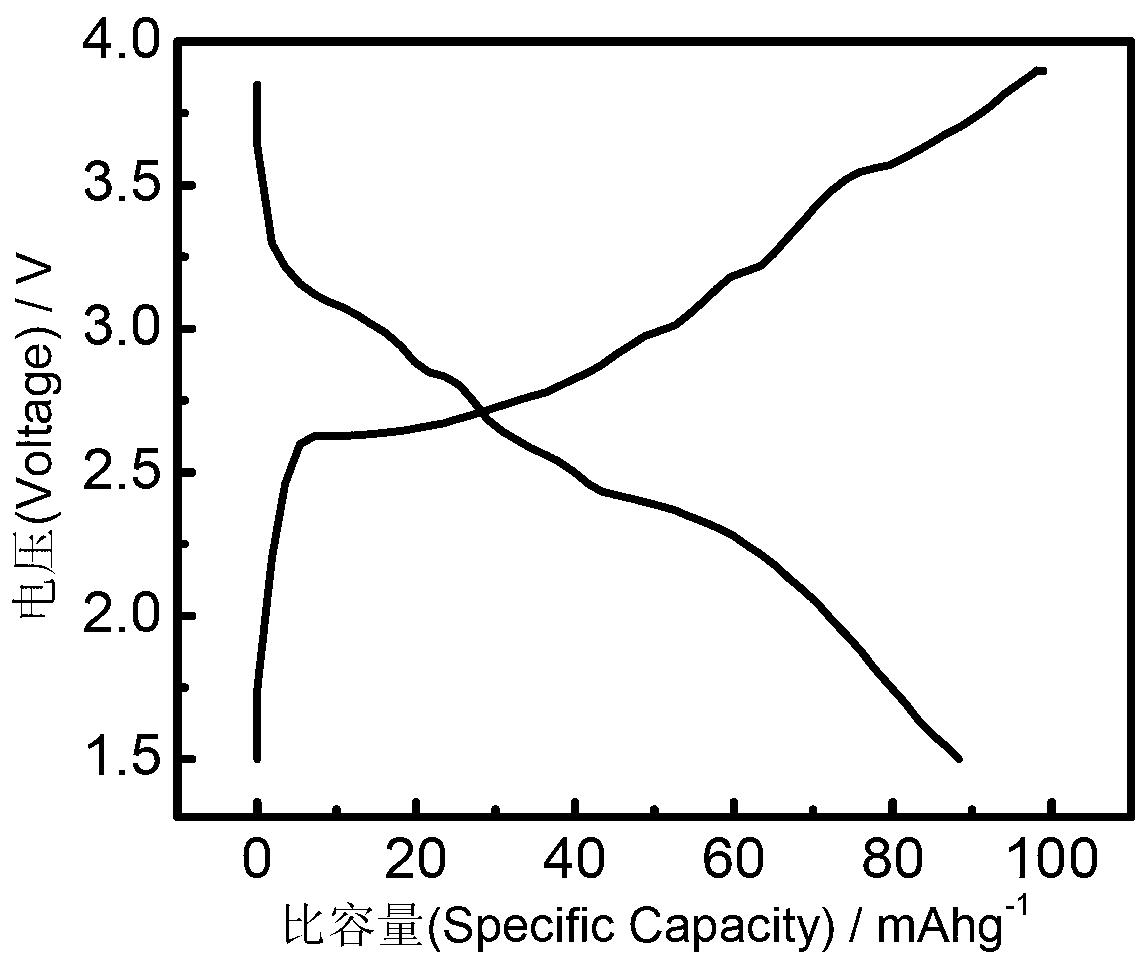

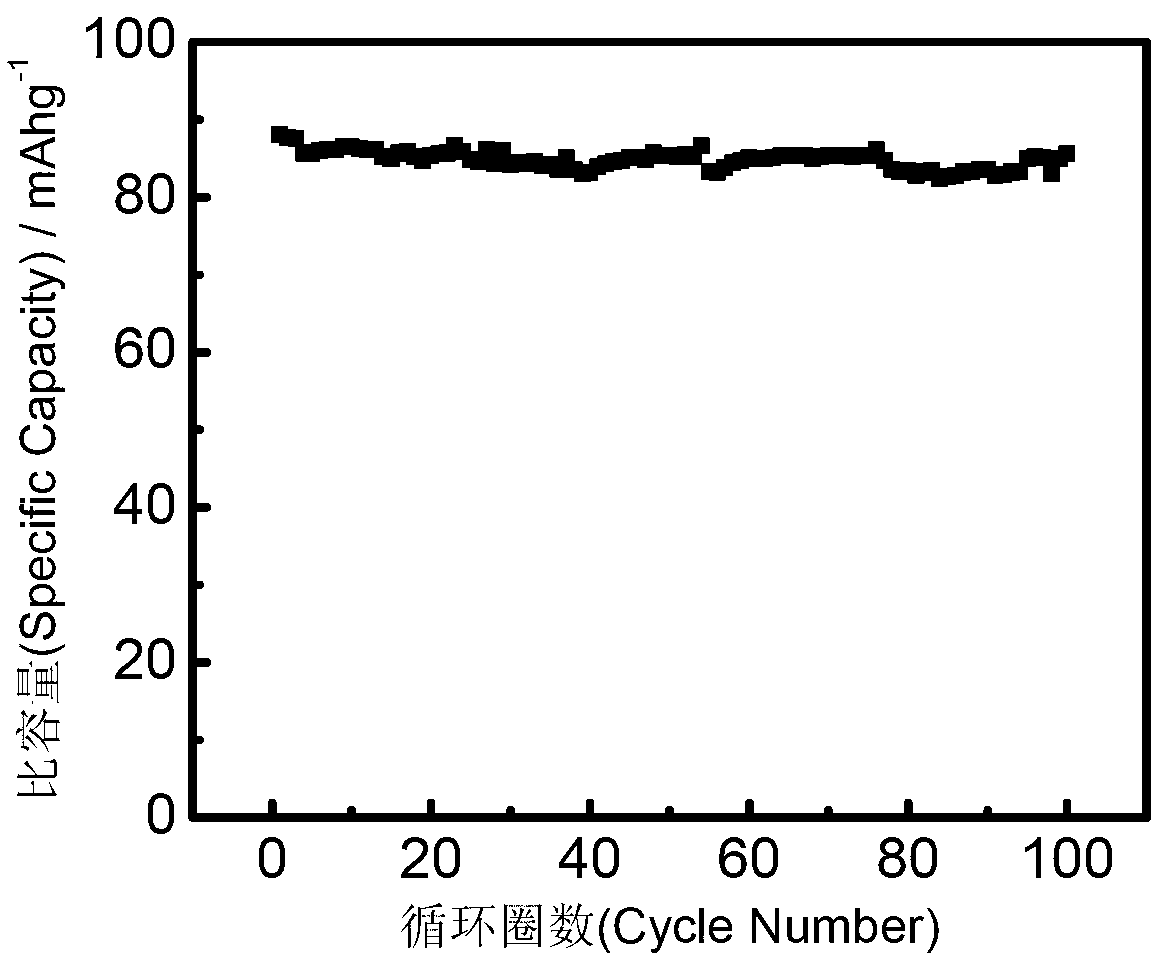

[0022] Commercial sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 *10H 2 O) and sodium chloride were weighed according to the molar ratio of 0.75:0.25, wherein the quality of sodium ferrocyanide was 3.63g, and the quality of sodium chloride was 0.1461g, and they were dissolved in 10mL of deionized water to form a mixed solution . Pipette 400mL of ethanol into the beaker, add a magnetic stirrer, place the beaker containing ethanol on a temperature-controllable and speed-adjustable magnetic stirrer, set the temperature to 20°C, and adjust the speed to 400r / min. The mixed solution was added to the stirring ethanol solution at a rate of 15 drops / min through a speed-adjustable peristaltic pump to obtain a yellowish precipitate. The precipitate was placed in a constant-temperature vacuum drying oven at 100° C. for 8 hours in vacuum to obtain sodium ferrocyanide-sodium chloride solid solution powder with a particle diameter of about 200 nm. Using this material as the positive elec...

Embodiment 3

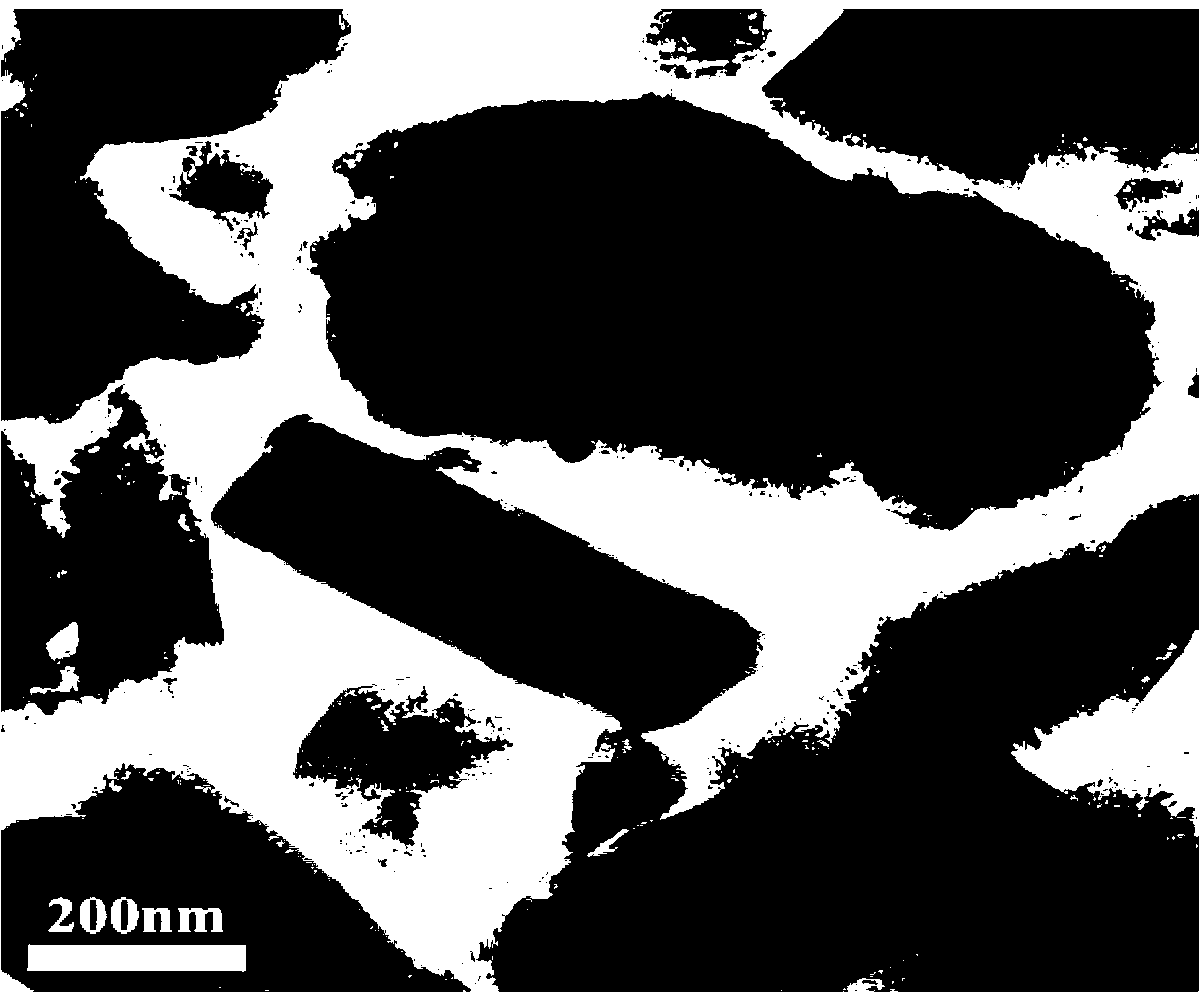

[0024] Commercial sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 *10H 2 O) and sodium chloride were weighed according to the molar ratio of 0.25:0.75, wherein the quality of sodium ferrocyanide was 4.84g, and the quality of sodium chloride was 1.7532g, and they were dissolved in 10mL of deionized water to form a mixed solution . Pipette 400mL of ethanol into the beaker, add a magnetic stirrer, place the beaker containing ethanol on a temperature-controllable and speed-adjustable magnetic stirrer, set the temperature to 20°C, and adjust the speed to 400r / min. The mixed solution was added to the stirring ethanol solution at a rate of 15 drops / min through a speed-adjustable peristaltic pump to obtain a yellowish precipitate. Place the precipitate in a constant temperature vacuum drying oven at 100°C for 8 hours in vacuum to obtain sodium ferrocyanide-sodium chloride solid solution powder with a particle diameter of about 500nm, such as image 3 shown. Using this material as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com