Speed sensorless vector control method for induction motor

A speed sensorless and vector control technology, applied in the field of sensorless vector control and vector control of induction motors, can solve problems such as too much dependence on motor parameters, too many PI regulators, complex motor models, etc., and achieve load capacity Strong, stable and reliable system, and small parameter dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description of the embodiments will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention. Changes in the definition of the present invention and / or formal but not substantial changes to the overall structure shall be regarded as the protection scope limited by the technical solutions of the present invention.

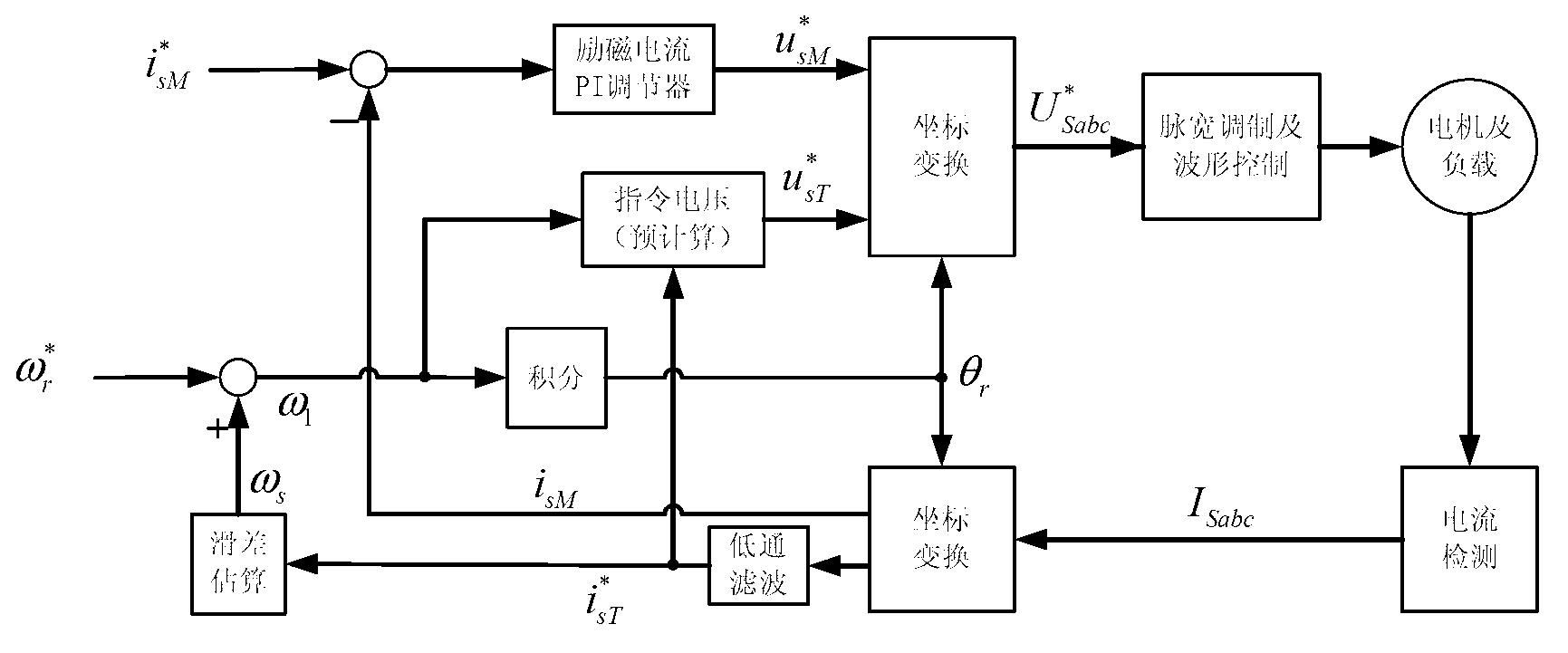

[0032] In this embodiment, the speed sensorless vector control method of an induction motor includes the following steps:

[0033] (1) Flux linkage control: According to the magnetic flux of the AC asynchronous motor, the command value of the excitation current is set, and then the closed-loop control of the excitation current is carried out through the PI regulator ACR;

[0034] (2) Coordinate transformation: According to the rotor flux linkage angle, 3S / 2S Clark transformation and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com