Preparation methods of granular red bean paste and red bean beverage

A red bean drink and red bean technology, applied in food preparation, dairy products, milk substitutes, etc., can solve the problems of manual water injection, water release, temperature control, waste of resources, difficult operation, etc., to avoid sewage treatment costs, improve production efficiency, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

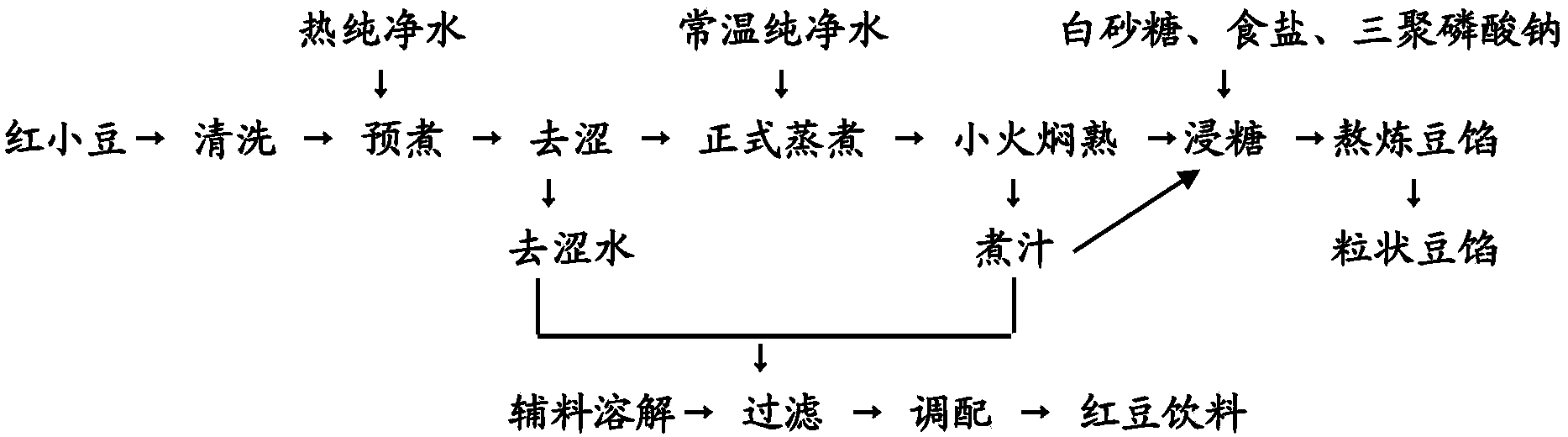

[0034] Preparation process such as figure 1 Shown:

[0035] (1) Wash, remove impurities and drain the selected red adzuki beans;

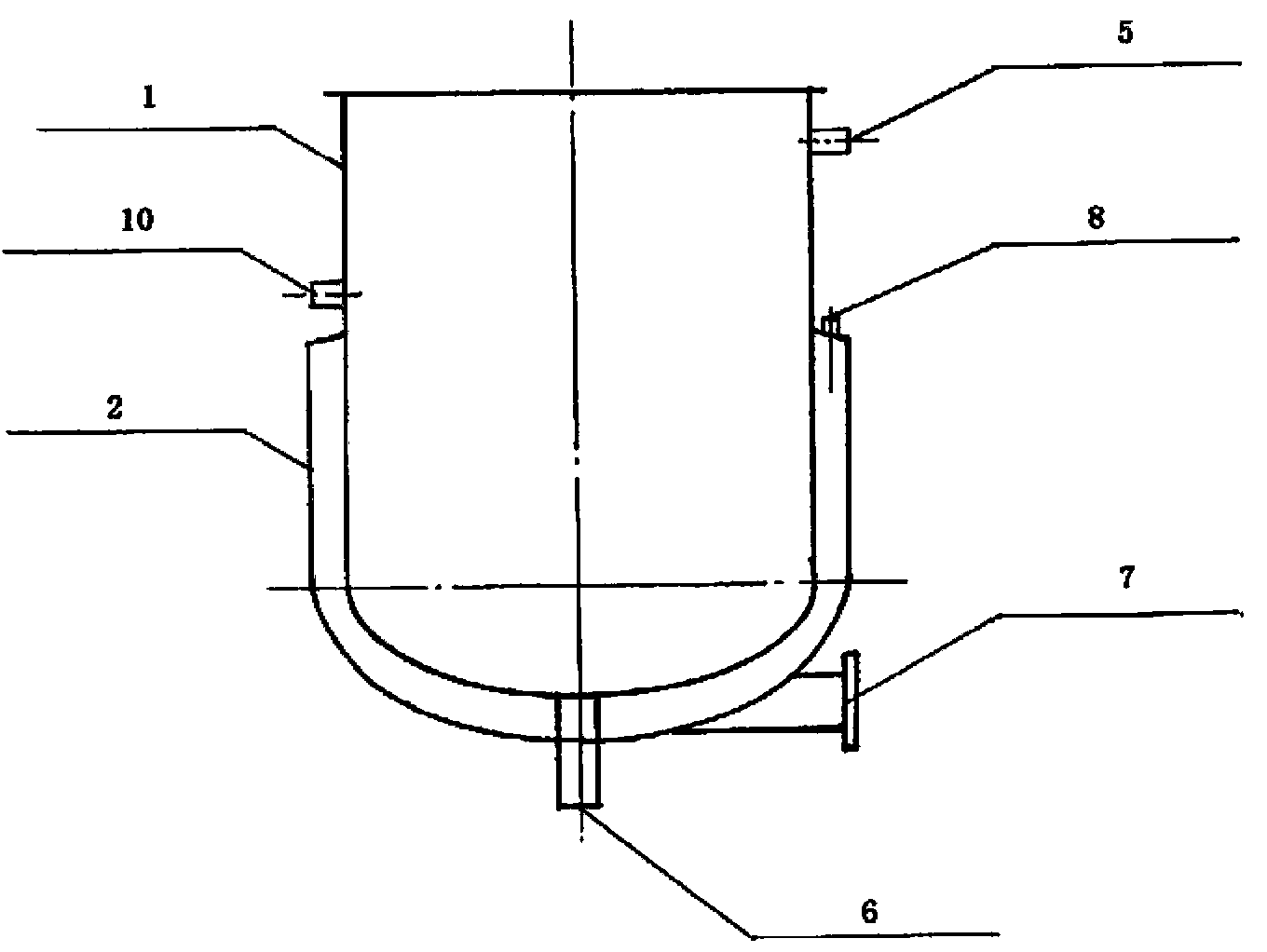

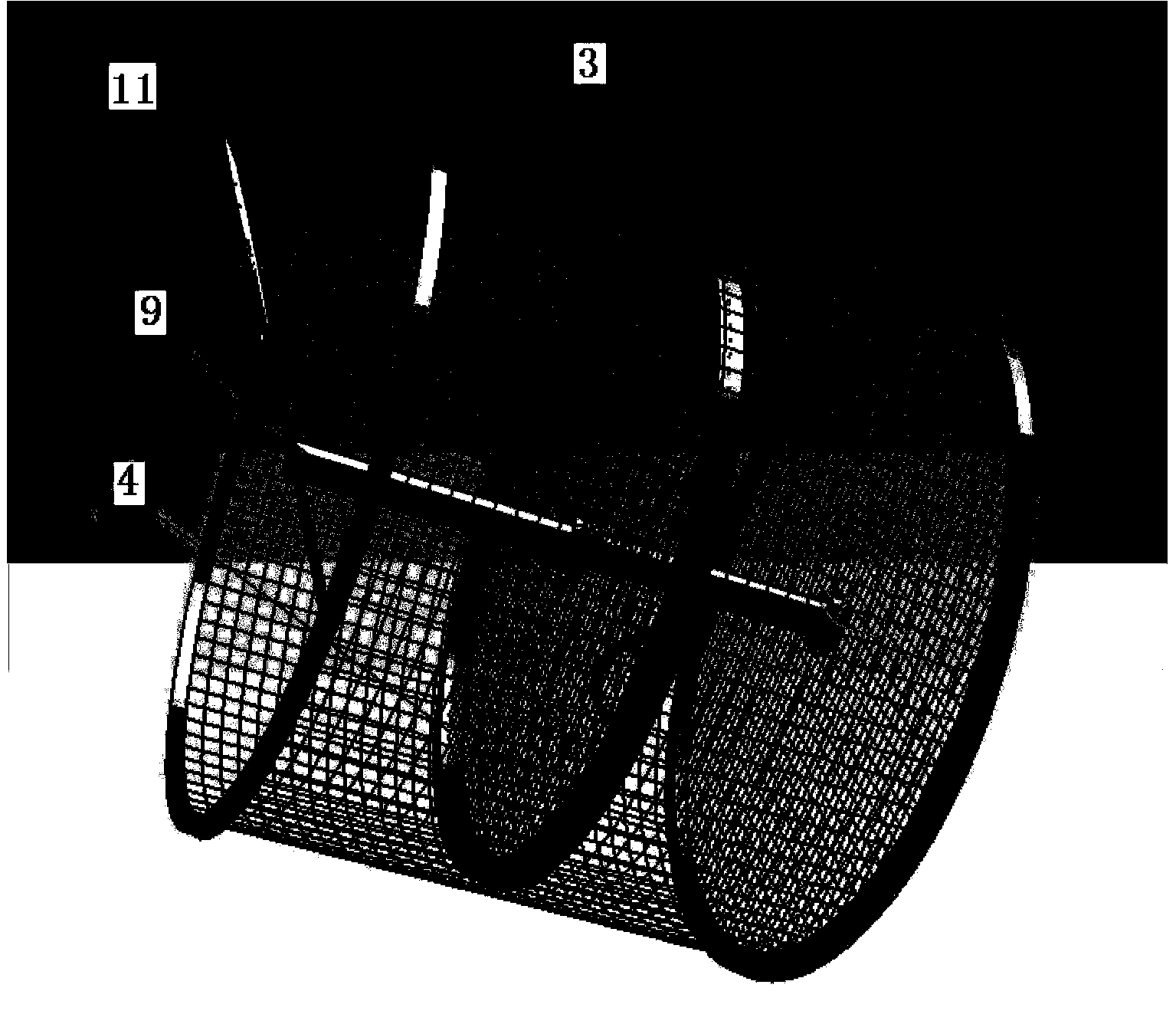

[0036] (2) To cooking equipment (such as figure 2 , Figure 3a with Figure 3b As shown), add 3 to 4 times the volume of purified water of red adzuki beans, heat directly to 60℃, pour in the washed red adzuki beans, cover the lid, stack the steamer, the steamer is stacked up and down, the diameter of the steamer is the same, red Place the adzuki beans in each steamer;

[0037] (3) Pre-cooking: continue to heat until boiling, change to low heat and keep boiling for 15 minutes, drain the astringent water (ie pre-cooked water) and wait for filtration;

[0038] (4) Formal steaming: add pure water at room temperature to the bean-cooking equipment, heat it to boiling, change to low heat and keep it boiling for 25 minutes, then turn off the heat and simmer for 15 minutes to drain the boiling juice. The supernatant part of the boiling juice is to be filtered, an...

Embodiment 2

[0045] The preparation method and the cooking equipment used are the same as in Example 1. The difference is that in step (2), the pure water is heated to 55°C with the remaining temperature of the last cooking, and the remaining temperature of the last cooking is used for heating, which saves energy. , Reduce production costs. Step (3) Pre-cooking process, keep boiling for 15 minutes on low heat. Step (4) The formal cooking process, heat to boiling, change to low heat and keep boiling for 20 minutes, then turn off the heat and simmer for 10 minutes. The granular red bean paste and the red bean beverage with good taste were obtained.

Embodiment 3

[0047] The preparation method and the cooking equipment used are the same as those in Example 1, except that in step (2), the purified water is directly heated to 65°C, and the residual temperature of the last cooking is used for heating, which saves energy and reduces production costs. Step (3) During the pre-cooking process, keep boiling for 20 minutes on a low fire. Step (4) The formal cooking process, heat to boiling, change to low heat and keep boiling for 30 minutes, then turn off the heat and simmer for 20 minutes. The granular red bean paste and the red bean beverage with good taste were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com