Device and process for performing purification treatment on stinky tail gas in waste water of gas production

A technology for tail gas purification and gas extraction wastewater, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problem that odorous tail gas cannot be completely treated, and achieves complete odor removal, high absorption capacity, and easy installation of equipment compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

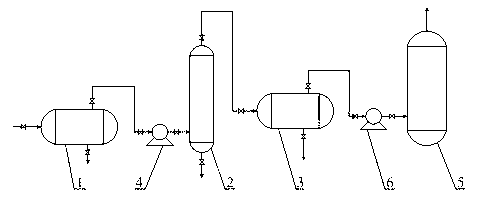

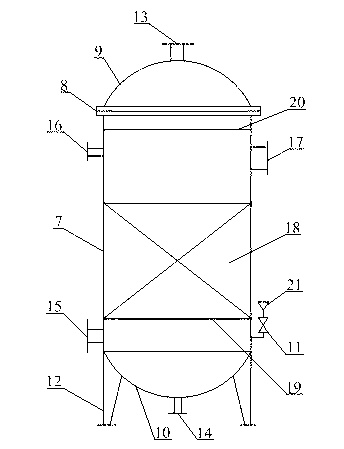

[0032] Such as figure 1 As shown, the malodorous tail gas purification and treatment device in gas extraction wastewater includes a first gas-liquid separation tank 1 , an oxidation absorption tower 2 , and a second gas-liquid separation tank 3 connected sequentially through pipelines.

[0033] In order to ensure that the gas phase separated by the first gas-liquid separation tank can completely and quickly enter the oxidation absorption tower, there is also a connection between the first gas-liquid separation tank 1 and the oxidation absorption tower 2 for transferring the gas phase through the first gas-liquid separation tank. The gas phase separated by the separation tank 1 is sucked into the first exhaust fan 4 in the oxidation absorption tower 2 .

[0034] In order to further purify the tail gas to achieve the best purification effect, the second gas-liquid separation tank 3 is also connected with an activated carbon adsorption tower 5 .

[0035] At the same time, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com