An automatic film transfer device

A rotary device and automatic technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of corrosion-prone mechanical parts such as belt transmission bearings, shortened service life of automatic transfer tables, and low rotary efficiency. , to achieve good tolerance, save labor costs, and increase the efficiency of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

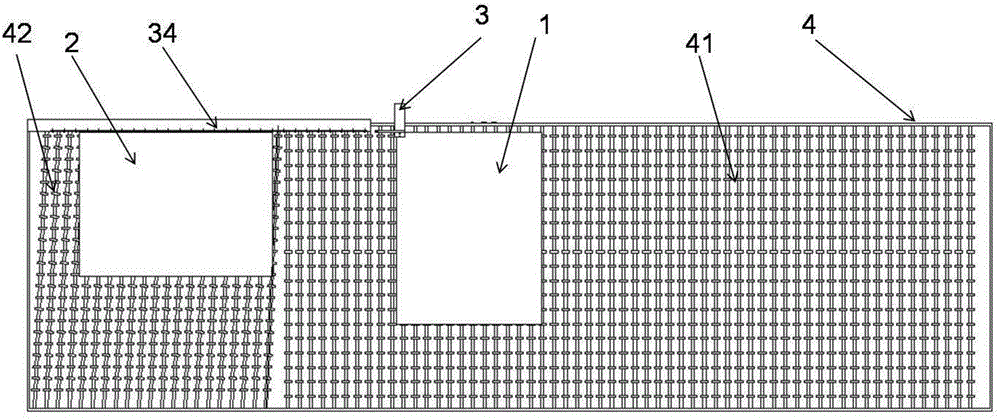

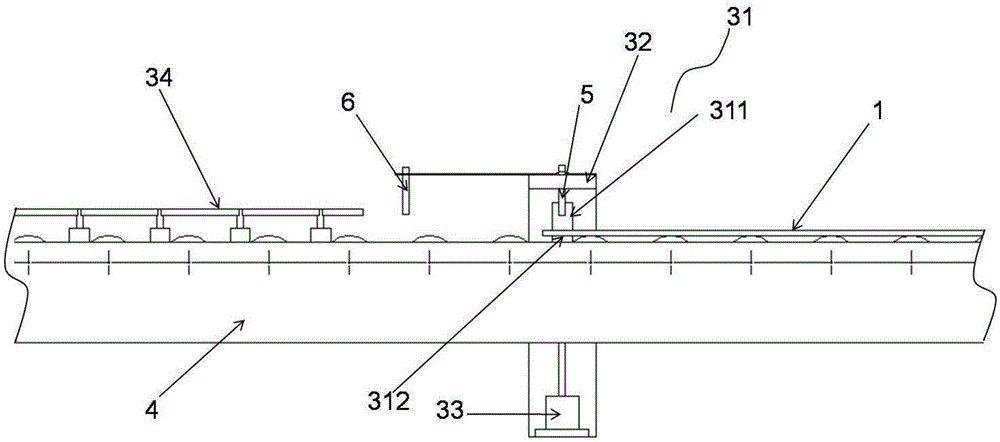

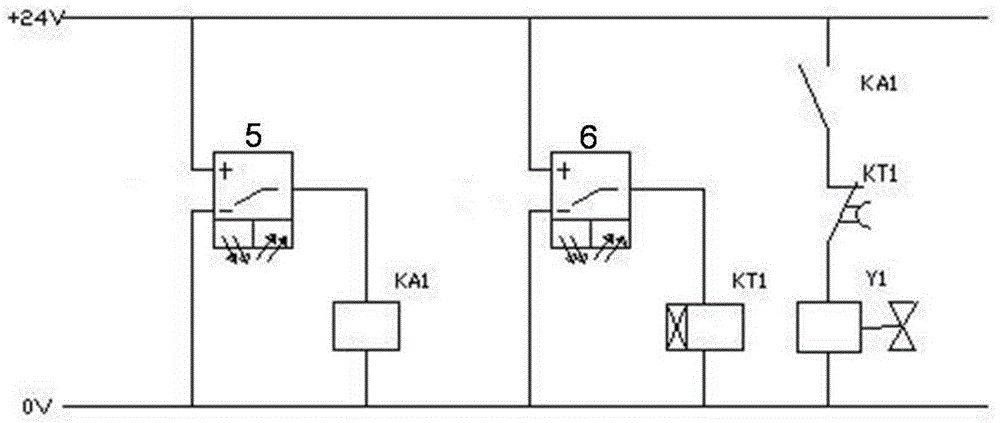

[0030] Such as figure 1 and 2 As shown, the present invention provides an automatic sheet-turning device, located between the first edger and the second edger, comprising an automatic sheet-turning mechanism 3, a glass delivery platform 4 and an automatic control system, the automatic sheet-turning mechanism 3 is connected to the first side of the glass conveying table 4, one end of the first side is connected to the first edger, the other end of the first side is connected to the second edger, the automatic sheet transfer mechanism 3 is connected to the Automatic control system electrical connection;

[0031] The automatic film transfer mechanism 3 includes a rotatable pressure wheel 31, a lift-type support frame 32, a cylinder 33 and a positioning grid 34, the lift-type support frame 32 is connected on the first side, and the lift-type support frame 32 includes a horizontal section and a fixed section. And support section, the horizontal section is positioned at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com