Automatic oil tank water draining system

An oil tank, automatic technology, applied in the field of oil tank automatic water cutting system, can solve the problems of no improvement in reliability and maintainability, unsuitable for viscous crude oil, difficult use and maintenance, etc. The effect of probability, convenient sampling, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

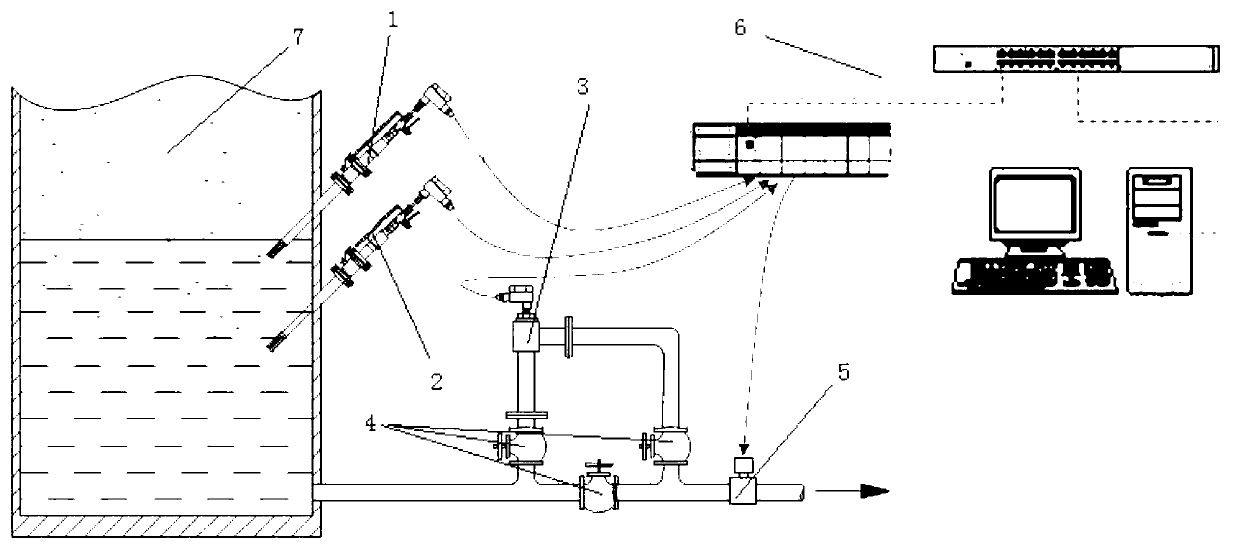

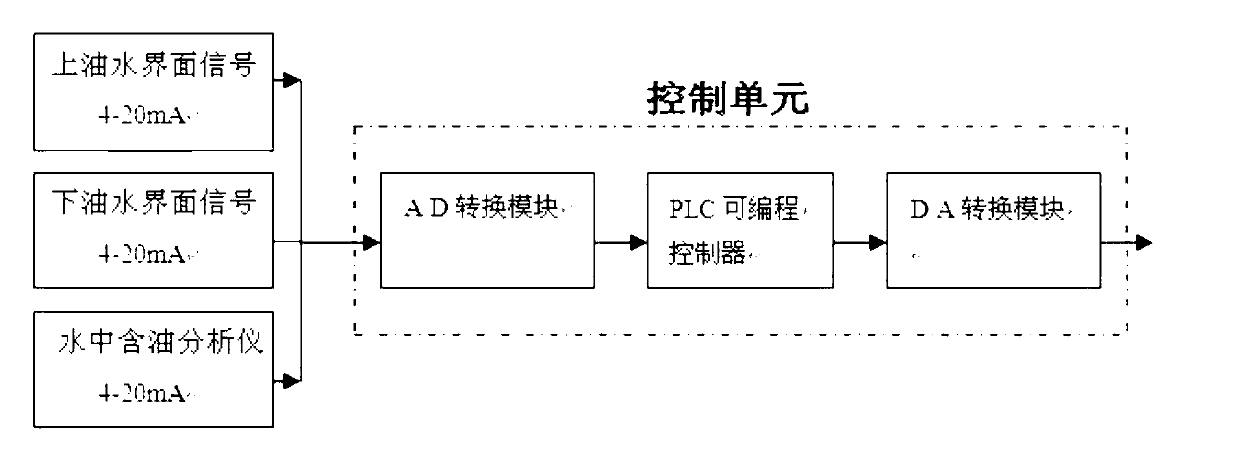

[0020] In order to make the content of the present invention more obvious and understandable, the following in conjunction with the attached figure 1 - attached figure 2 and specific implementation methods for further description.

[0021] Such as figure 1 As shown, the automatic water cutting system of the oil tank of the present invention includes an oil tank 7, a detection unit, a control unit 6 and an execution unit 5; The quantity is detected and the detection result is sent to the control unit, and the control unit analyzes the result sent by the detection unit and controls the work of the execution unit;

[0022] The detection unit includes an upper oil-water interface detector 1, a lower oil-water interface detector 2, and an oil-in-water analyzer 3; the upper oil-water interface detector 1 and the lower oil-water interface detector 2 extend obliquely into the oil tank 7 Inside, the oil-in-water analyzer 3 is connected to the oil tank 7 through a discharge pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com