Preparation method for inorganic noninflammable lightweight foamed cement

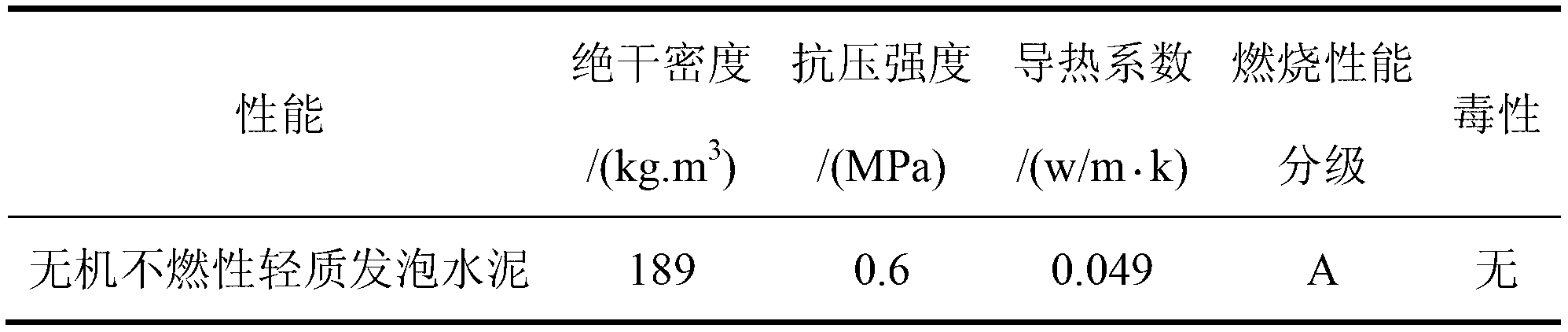

A foamed cement and inorganic technology, which is applied in the field of preparation of foamed cement for thermal insulation materials, can solve the problems of releasing toxic gases, hidden dangers of fire safety, easy combustion, etc., and achieve the effect of realizing ecological cycle and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Add 1.1g of sodium carboxymethylcellulose into 110mL of water, let it stand to fully dissolve sodium carboxymethylcellulose into the water, and obtain an aqueous solution of sodium carboxymethylcellulose;

[0028] 2) Add 10g of papermaking lime mud fiber (purchased from Hebi Jielian New Material Technology Co., Ltd.) into the sodium carboxymethylcellulose aqueous solution in batches, then stir with a glass rod, and then fully stir with a mixer to make the paper The white mud fiber is uniformly dispersed in the sodium carboxymethyl cellulose aqueous solution, and then successively add 1.5g of polypropylene fiber, 160g of cement, 0.38g of perlite, 1g of calcium stearate and 0.4g of manganese dioxide and stir uniform; then add 1mL of triethanolamine and 15.0mL of 30% hydrogen peroxide and stir for 15s, quickly put into the mold, harden and form, after 2 days for final coagulation, demoulding, natural curing in the room for 20 days to the test age, that is, the inorganic ...

Embodiment 2

[0031] 1) Add 1.2g of sodium carboxymethylcellulose into 140mL of water, let it stand to fully dissolve sodium carboxymethylcellulose into the water, and obtain an aqueous solution of sodium carboxymethylcellulose;

[0032] 2) Add 19g of papermaking lime mud fiber (purchased from Hebi Jielian New Material Technology Co., Ltd.) into the sodium carboxymethylcellulose aqueous solution in batches, then stir with a glass rod, and then fully stir with a mixer to make the paper The white mud fiber is uniformly dispersed in the aqueous solution of sodium carboxymethyl cellulose, then successively add 1.5g of polypropylene fiber, 140g of cement, 0.38g of perlite, 1g of calcium stearate and 0.4g of manganese dioxide and stir uniform; then add 1mL of triethanolamine and 15.0mL of 30% hydrogen peroxide and stir for 15s, quickly put into the mold, harden and form, after 2 days for final coagulation, demoulding, natural curing in the room for 20 days to the test age, that is, the inorganic ...

Embodiment 3

[0035] 1) Add 1.2g of sodium carboxymethylcellulose into 150mL of water, let it stand to fully dissolve sodium carboxymethylcellulose into the water, and obtain an aqueous solution of sodium carboxymethylcellulose;

[0036] 2) Add 24g of paper-making lime mud fiber (purchased from Hebi Jielian New Material Technology Co., Ltd.) into the sodium carboxymethylcellulose aqueous solution in batches, then stir with a glass rod, and then fully stir with a mixer to make the paper The white mud fiber is dispersed evenly in the aqueous solution of sodium carboxymethyl cellulose, and then 2g of polypropylene fiber, 140g of cement, 0.38g of perlite, 1g of calcium stearate and 0.4g of manganese dioxide are added in sequence and stirred evenly ; Add 1mL of triethanolamine and 15.0mL of 30% hydrogen peroxide and stir for 15s, quickly put into the mold, harden and form, after 2 days for final setting, demoulding, and natural curing in the room for 20 days to the test age, that is, the inorgani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com