Water-based heat transfer printing ink and preparation method thereof

A thermal transfer printing and ink technology, applied in ink, dyeing, textiles and papermaking, etc., can solve the problems of stability problems, such as dispersion system, difficult drying, etc., to achieve good printing stability, good drying, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

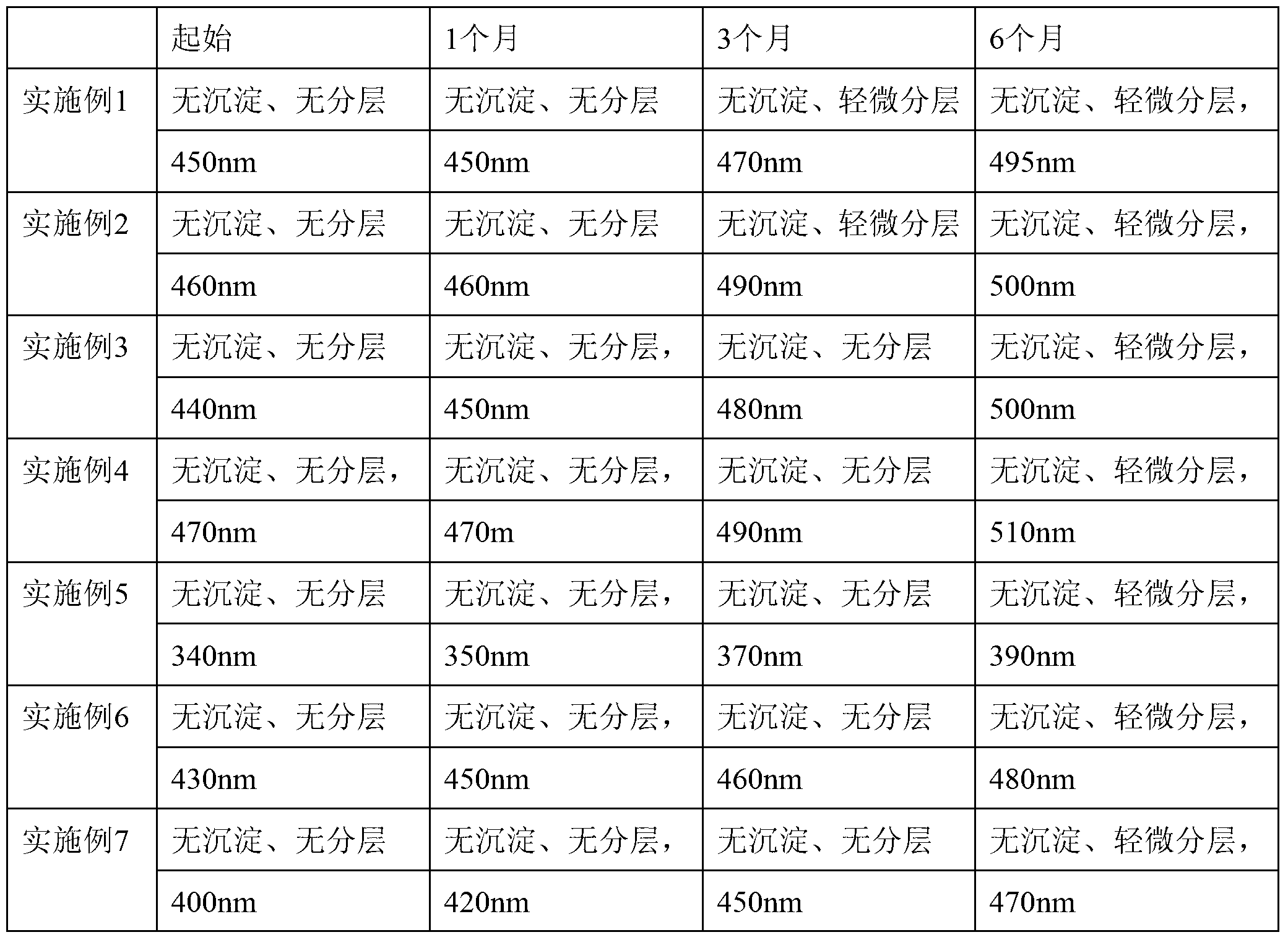

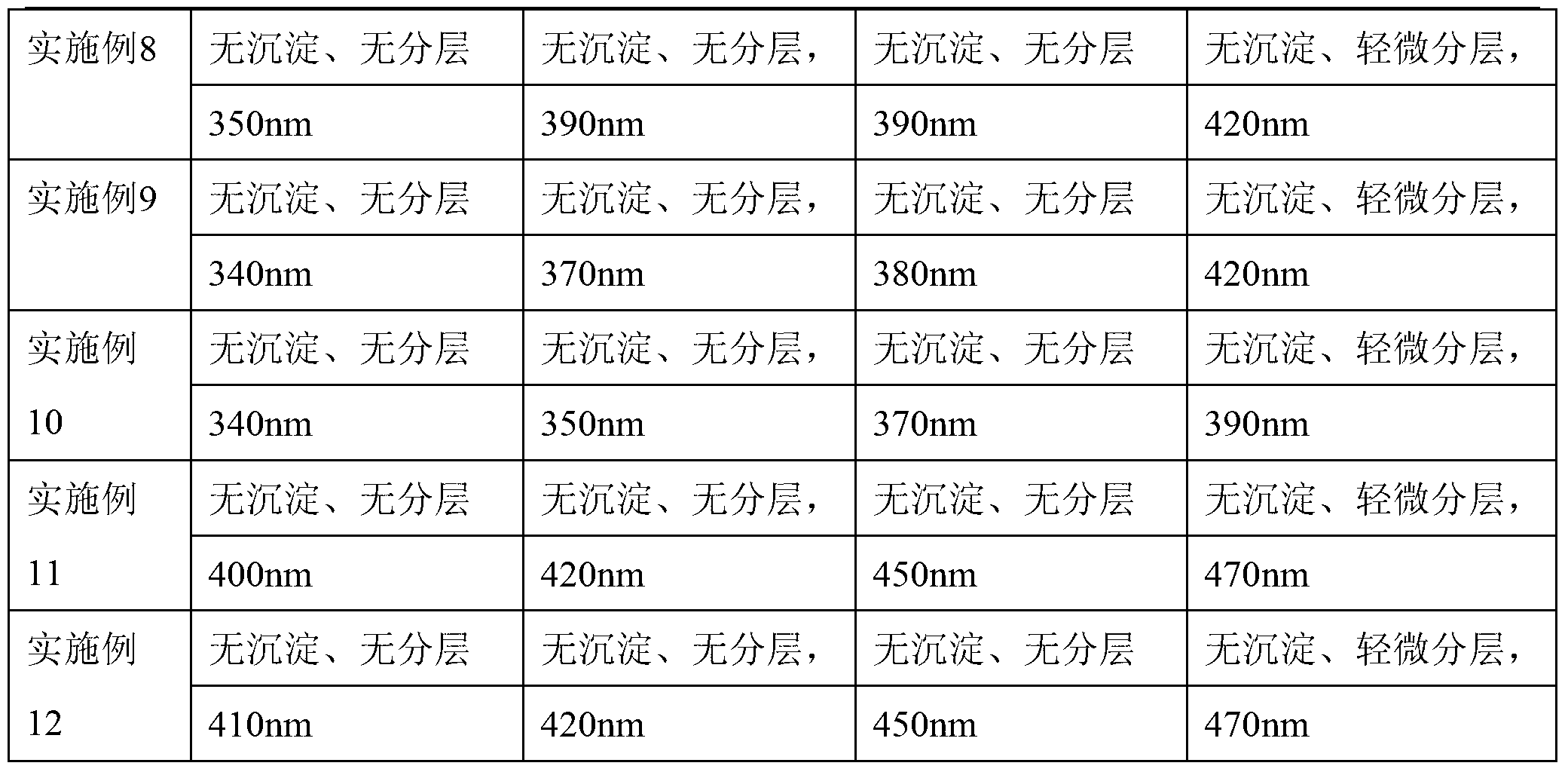

Embodiment 1

[0031] Fully dissolve 10 parts of dispersant MF (produced by Shangyu Haili Chemical Industry) and 1 part of dispersant SILCO SPERSE HLD-11 / C (produced by German Silcona Company) in 60 parts of water, and then add 2 parts of thickener EBS451FQ (produced by AKZO NOBEL Company 2% aqueous solution, 0.3 part of wetting agent Surfynol AD01 (produced by American Air Chemical Company), 0.2 part of defoamer Surfynol DF-37 (produced by American Air Chemical Company) are mixed in the solution obtained above, and fully mixed After stirring, add 15 parts of Disperse Red 60, and stir thoroughly again to obtain a pre-dispersion. Pass the predispersion through the containing After the zirconia beads were refined 4 times in a horizontal sand mill, a dispersion with a particle size of about 450 nm was obtained.

[0032] Add 0.05 parts of preservative Kathon LXE (produced by Rohm and Haas, USA), 5 parts of ethanol, 5 parts of ethylene glycol, and 0.5 parts of drier zirconium isooctanoate to th...

Embodiment 2

[0034] Fully dissolve 10 parts of dispersant Reax85A (produced by Westvaco, U.S.) and 3 parts of dispersant polyethylene glycol 600 in 60 parts of water, then mix 2 parts of 3% aqueous solution of thickener PUR2150 (produced by AKZO NOBEL), 0.3 parts Wetting agent SILCO WET D500 (produced by German SILCONA company), 0.2 parts of defoamer Surfynol110D (produced by American Air Chemical Company) are mixed in the solution obtained above, after fully mixing and stirring, add 15 parts of disperse red 60, and fully stir again to obtain a predispersion. Pass the predispersion through the containing The zirconia beads were refined 4 times in a horizontal sand mill to obtain a dispersion with a particle size of about 460 nm.

[0035] Add 0.05 parts of preservative Kathon LXE (produced by Rohm and Haas Company of the United States), 5 parts of isopropanol, 5 parts of glycerin, and 0.5 parts of drier zirconium isooctanoate to the dispersion liquid obtained above, stir and mix evenly, a...

Embodiment 3

[0037] 10 parts of dispersant dispersant NNO and 3 parts of dispersant Pingping plus O are fully dissolved in 60 parts of water, and then 1 part of 50% aqueous solution of thickener RM-5000 (produced by Rohm and Haas, USA), 0.3 parts Wetting agent Surfynol 420 (produced by American Air Chemical Company) and 0.2 parts of defoamer Surfynol DF-37 (produced by American Air Chemical Company) were mixed in the solution obtained above, after fully mixing and stirring, 15 parts of Disperse Red 60 were added, and again Stir thoroughly to obtain a predispersion. Pass the predispersion through the containing The zirconia beads were refined 4 times in a horizontal sand mill to obtain a dispersion with a particle size of 470 nm.

[0038] Add 0.05 parts of preservative Kathon LXE (produced by Rohm and Haas Company of the United States), 5 parts of isopropanol, 5 parts of glycerin, and 0.5 parts of drier zirconium isooctanoate to the dispersion liquid obtained above, stir and mix evenly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com