Adhesive composition for ink powder and preparation method of adhesive composition

A technology of composition and adhesive, applied in the direction of developer, instrument, optics, etc., can solve the problems of low-temperature fixability, offset resistance, and storage stability, etc., and achieve excellent low-temperature fixability and increase compatibility. , good effect of high temperature offset resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

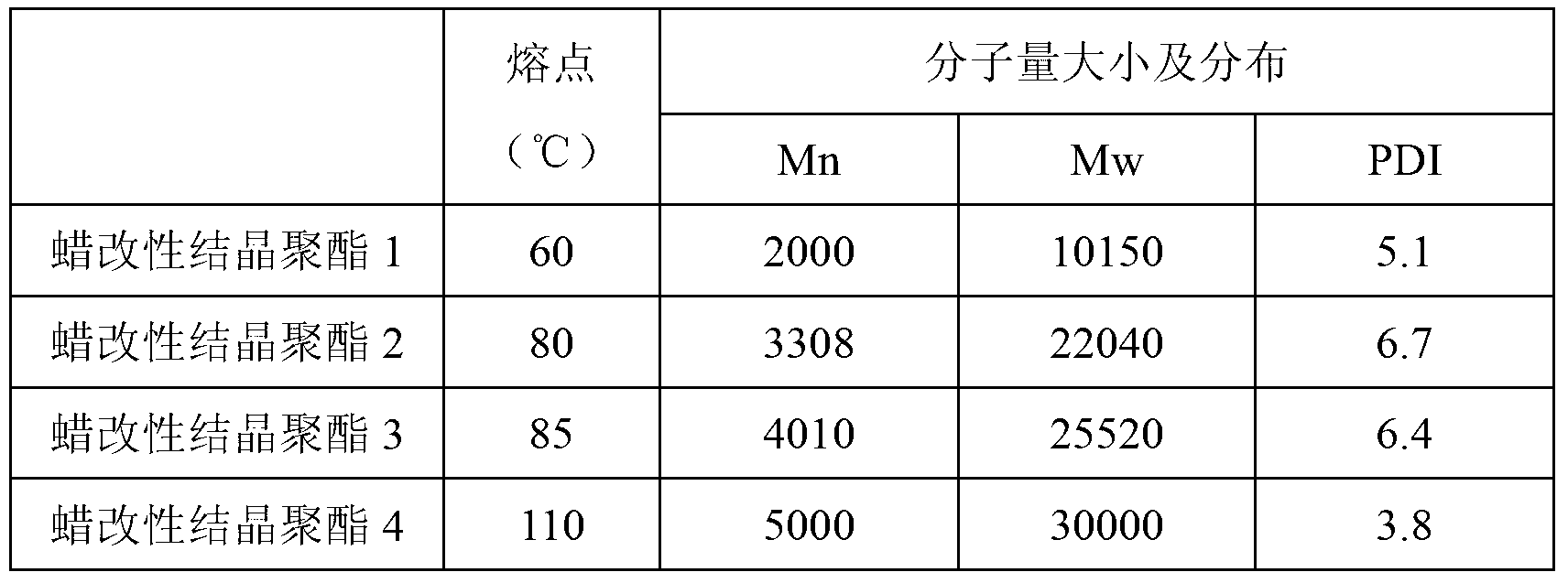

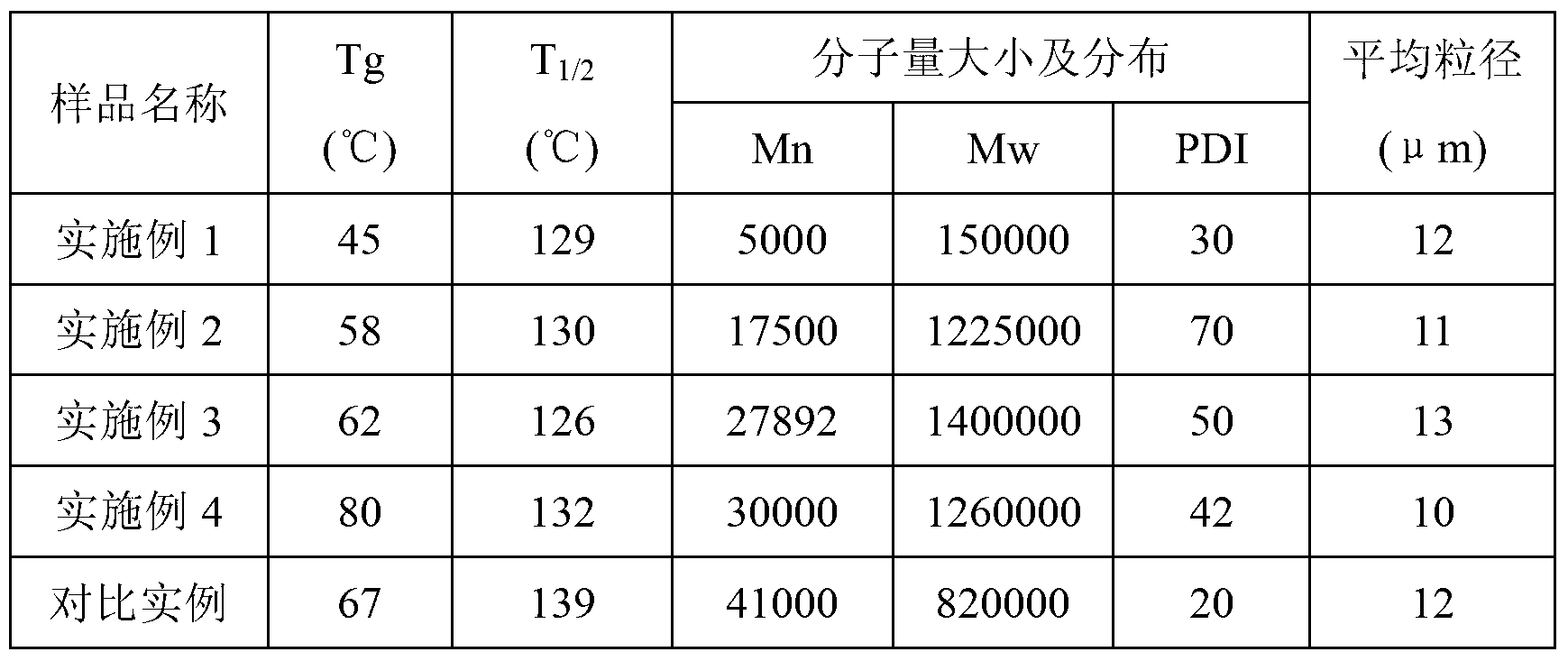

Embodiment 1

[0051] Put 100 parts of xylene into the reaction kettle, then blow it with nitrogen, replace all the air in the kettle, gradually raise the temperature to 138°C, and drop the mixed solution in the state of xylene reflux (the composition of the mixed solution is 60 parts of styrene , 12 parts of butyl methacrylate, 12 parts of hexyl acrylate, 6 parts of acrylic acid, 5 parts of ethylene glycol, 0.6 parts of initiator, 0.3 parts of crosslinking agent, 0.1 part of catalyst), added dropwise for 5 hours. Take 1,17 parts of wax-modified crystalline polyester, melt it at a temperature higher than its melting point, then add it dropwise to the reaction system, keep it warm for 3 hours, carry out vacuum extraction to a negative pressure of 0.08MPa, and keep it empty for 2 hours , pressurize and discharge with nitrogen. Cool to room temperature, pulverize, finely powder, and sieve to obtain binder composition 1.

Embodiment 2

[0053] Put 200 parts of xylene into the reaction kettle, then blow it with nitrogen, replace all the air in the kettle, gradually raise the temperature to 138°C, and drop the mixed solution in the state of xylene reflux (the composition of the mixed solution is 65 parts of styrene , 8 parts of butyl methacrylate, 9 parts of hexyl acrylate, 10 parts of acrylic acid, 8 parts of ethylene glycol, 0.3 parts of initiator, 0.6 parts of crosslinking agent, 0.1 part of catalyst), added dropwise for 5 hours. Take 2,10 parts of wax-modified crystalline polyester, melt it at a temperature higher than its melting point, then add it dropwise to the reaction system, keep it warm for 3 hours, carry out vacuum extraction to a negative pressure of 0.08MPa, and keep it empty for 2 hours , pressurize and discharge with nitrogen. Cool to room temperature, pulverize, finely powder, and sieve to obtain binder composition 2.

Embodiment 3

[0055] Put 300 parts of xylene into the reaction kettle, then blow it with nitrogen, replace all the air in the kettle, gradually raise the temperature to 138°C, and drop the mixed solution in the state of xylene reflux (the composition of the mixed solution is 55 parts of styrene , 10 parts of butyl methacrylate, 10 parts of hexyl acrylate, 10 parts of acrylic acid, 10 parts of ethylene glycol, 0.5 parts of initiator, 0.4 parts of crosslinking agent, 0.1 part of catalyst), added dropwise for 5 hours. Take 3 or 7 parts of wax-modified crystalline polyester, melt it at a temperature higher than its melting point, then add it dropwise to the reaction system, keep it warm for 3 hours, carry out vacuum extraction to a negative pressure of 0.08MPa, and keep it empty for 2 hours , pressurize and discharge with nitrogen. Cool to room temperature, pulverize, finely powder, and sieve to obtain binder composition 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com