Periodic permanent magnetic structure

A technology of periodic permanent magnets and permanent magnets, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of the structure description of the magnetic focusing system, the increase of the volume of the permanent magnet focusing system, and the disadvantage of miniaturization of the traveling wave tube, and achieve strong performance. Practical value, favorable for miniaturization, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

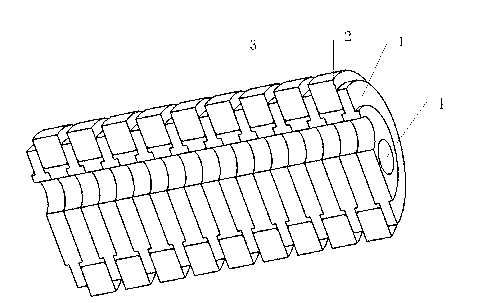

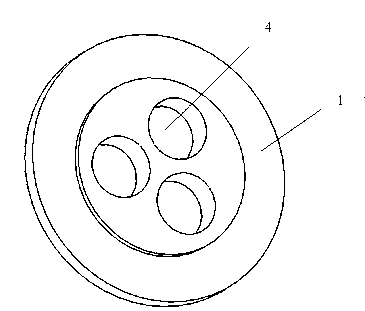

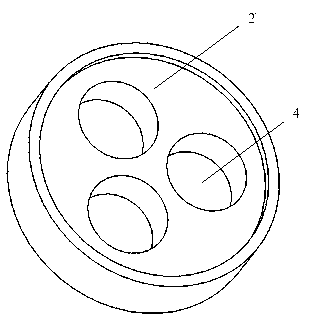

[0044] Example 1: figure 1 It is a periodic permanent magnet structure with three electron injection channels. figure 2 is the structure of the pole shoe (1). image 3 is the structure of the positioning ring (2). The diameter of the electron injection channel of this embodiment is 2.2mm, the period of the periodic permanent magnet structure is 5.6mm, the peak value of the axial magnetic flux density of the electronic injection channel is 218mT, and the ratio of the peak value of the radial magnetic flux density to the peak value of the axial magnetic flux density was 0.52%. Figure 4 is the magnetic flux density distribution diagram of the electron beam channel on the central axis in this example, in Figure 4 middle, B R is the radial magnetic flux density, B Z / 100 is one hundredth of the axial magnetic flux density.

Embodiment 2

[0045] Example 2: Figure 5 It is a periodic permanent magnet structure of four electron injection channels. The diameter of the electronic injection channel of this embodiment is 2.2mm, the period of the periodic permanent magnet structure is 5.6mm, the axial peak magnetic flux density of the electronic injection channel is 218mT, and the radial magnetic The ratio of the peak flux density to the peak axial flux density is 1.02%. Figure 6 is the magnetic flux density distribution diagram on the central axis of the electron beam channel in this example, in Figure 6 middle, B R is the radial magnetic flux density, B Z / 100 is one hundredth of the axial magnetic flux density.

Embodiment 3

[0046] Example 3: Figure 7 It is a periodic permanent magnet structure of five electron injection channels. The diameter of the electronic injection channel in this embodiment is 2.2mm, and the period of the periodic permanent magnet structure is 5.6mm. The peak value of the axial magnetic flux density of the electronic injection channel is 220mT, and the radial magnetic flux The ratio of the peak density to the peak axial flux density is 1.78%; Figure 8 is the magnetic flux density distribution diagram on the central axis of the electron beam channel in this example, in Figure 8 middle, B R is the radial magnetic flux density, B Z / 100 is one hundredth of the axial magnetic flux density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com