Betel nut processing device

A processing equipment and betel nut technology, applied in the field of betel nut processing equipment, can solve the problems of inaccurate positioning of betel nut, different shapes of betel nut, complex structure and the like, and achieve the effects of neat shape, high yield and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

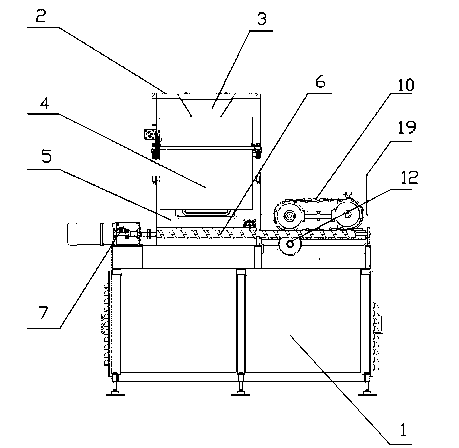

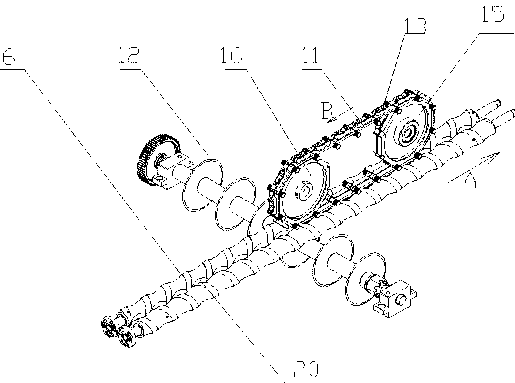

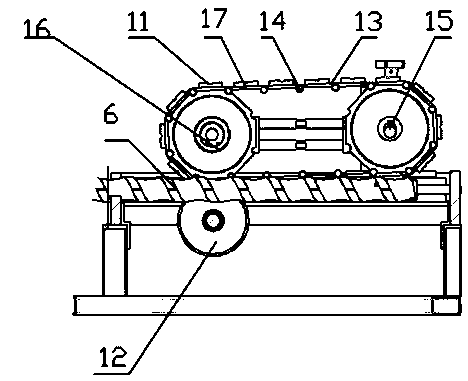

[0027] In Embodiment 1, a kind of betel nut processing equipment has a seed cutting machine 32, and the seed cutting machine 32 includes a frame 1, a feeding part, a conveying part and a cutter 12, and the conveying part includes many pairs of screw rods 6 and the screw pair drive box 7, the screw pair 6 has a plurality of positioning gaps 20, a cover plate 21 is provided between adjacent screw pairs 6, the screw pair 6 is driven by the screw pair drive box 7, and the screw pair The drive box 7 is connected with a synchronizer transmission box 8, and the synchronizer transmission box 8 is connected with a synchronous wire speed box 9, and the synchronous wire speed box 9 is connected with a plurality of clamping parts 10, and the clamping parts 10 A positioning clamp 11 is provided, the center line of the positioning clamp 11 coincides with the center line of the screw pair 6, the clamping part 10 is arranged above the cutting knife 12, and the cutting knife 12 part Through th...

Embodiment 2

[0031] In embodiment 2, also have a seed selection machine 33, described seed selection machine 33 comprises frame 22, feed hopper 23, multilayer seed selection frame 24, storage box 25, and described seed selection frame comprises many pairs of The screw pair 6 and the screw pair drive box 7, the screw pair 6 has a plurality of positioning gaps 20, the screw pair 6 is driven by the screw pair drive box 7, and the two sides of the end of the seed selection frame are provided with The discharge port 26 , the discharge port 26 is connected to the upper end of a discharge straight pipe 27 , and the bottom end of the discharge straight pipe 27 is connected to the storage box 25 . The end of at least one layer of the seed selection frame 24 is also movably provided with a transmission mechanism 29, and the transmission mechanism (29) is connected to the upper feeder (2). The seed selection machine 33 is also provided with a bottom ash plate 30, the bottom ash plate 30 is located be...

Embodiment 3

[0034] In Embodiment 3, there is also a conveyor 28 connected to the feed hopper 23 . By using the conveyer 28, the continuity of the conveying process is realized, and the efficiency of the betel nut processing is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com