Process for preparing pinacolone and compound catalyst

A composite, catalyst technology, applied in the condensation preparation of carbonyl compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing the production cost of pinacolone, reducing the economic benefits of enterprises, Long reaction time and other problems, to achieve the effect of reducing production costs, considerable economic benefits, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] 1. Preparation of pinacolone: Condensation reaction of pentachloride and formaldehyde under acidic conditions, catalyzed by Zn / Co / Sb composite catalyst, the reaction temperature is 60-95°C, and the reaction time is 4-5h.

[0016] 2. The condensation product pinacolone is assayed using a gas chromatograph with a hydrogen flame, and the parameters set are:

[0017] Chromatographic column: 30m×0.3mm, film thickness 0.45μm, 0V-01 capillary column, sensitivity (yang)=1, split ratio 1:100, carrier gas is nitrogen, detection chamber temperature 180°C, vaporization chamber temperature 180°C, column The initial temperature was 50°C, kept for 2 minutes, and then raised to 100°C at a rate of 10°C / min.

[0018] The effects of Zn / Co / Sb composite catalyst, reaction temperature and reaction time on the content and yield of pinacolone are studied respectively below.

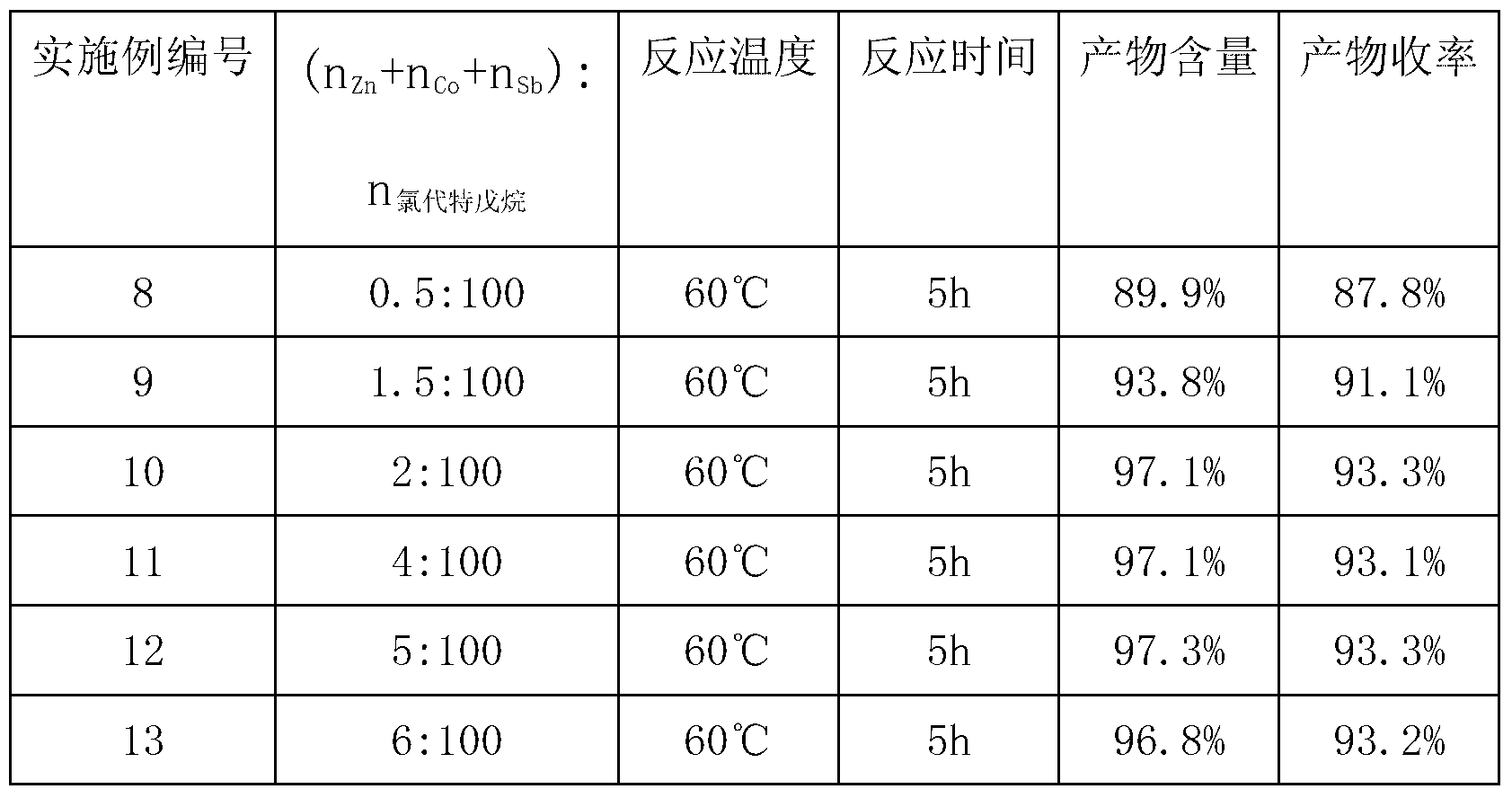

[0019] 1. Effect of Zn / Co / Sb composite catalyst on pinacolone content and yield

[0020] Restricted condition: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com