Flame-retardant plastic modified material for extrusion molding of automobile corrugated pipe, and preparation method thereof

A technology of extrusion molding and modified materials, which is applied in the field of plastic modified materials and can solve problems such as poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

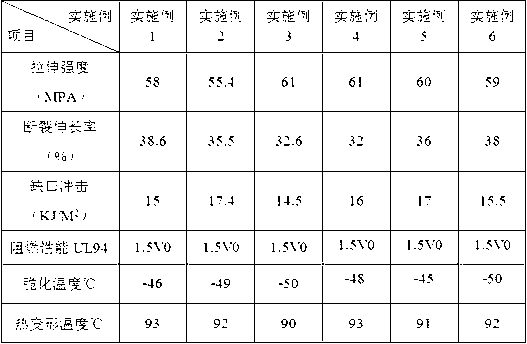

Examples

Embodiment 1

[0116] A flame-retardant plastic modified material for extrusion molding of automobile bellows, which consists of the following raw materials in parts by weight: 40 parts of PA6 resin with a viscosity of 2.8mpa.s, 15 parts of LDPE resin, 5 parts of PA12, 5 parts of EPDM-G-MAH, 18 parts of DBDPE, Sb 2 o 3 5 parts, black mother 2 parts, antioxidant 1010 0.2 parts, zinc stearate 0.3 parts, EBS 0.3 parts, methyl silicone oil 0.2 parts.

[0117] A method for preparing a flame-retardant plastic modified material for extrusion molding of automobile bellows, comprising the following preparation steps:

[0118] Step A. by weight, PA6 resin, LLDPE resin, PA12, EPDM-G-MAH, DBDPE, Sb 2 o 3 , black masterbatch, antioxidant 1010, zinc stearate, EBS, and methyl silicone oil were put into a high-speed mixer and stirred for 3 minutes to form mixture I;

[0119] Step B. Put the mixture I into a twin-screw extruder, melt and extrude at 230°C, and then cool, air-dry, and pelletize to obtain ...

Embodiment 2

[0121] A flame-retardant plastic modified material for extrusion molding of automobile bellows, which consists of the following raw materials in parts by weight: 35 parts of PA6 resin with a viscosity of 2.8mpa.s, 16 parts of LLDPE resin, 10 parts of PA12, EPDM-G-MAH 7 parts, DBDPE 20 parts, Sb 2 o 3 6 parts, 2 parts of black mother, 0.2 part of antioxidant 1010, 0.3 part of zinc stearate, 0.3 part of EBS, 0.2 part of methyl silicone oil.

[0122] A method for preparing a flame-retardant plastic modified material for extrusion molding of automobile bellows, comprising the following preparation steps:

[0123] Step A. by weight, PA6 resin, LLDPE resin, PA12, EPDM-G-MAH, DBDPE, Sb 2 o 3 , black masterbatch, antioxidant 1010, zinc stearate, EBS, and methyl silicone oil were put into a high-speed mixer and stirred for 3 minutes to form mixture I;

[0124] Step B. Put the mixture I into a twin-screw extruder, melt and extrude at 232°C, and then cool, air-dry, and pelletize to ob...

Embodiment 3

[0126] A flame-retardant plastic modified material for extrusion molding of automobile bellows, which consists of the following raw materials in parts by weight: 45 parts of PA6 resin with a viscosity of 2.8mpa.s, 15 parts of LLDPE resin, 10 parts of PA12, EPDM-G-MAH 5 parts, DBDPE 18 parts, Sb 2 o 3 5 parts, black mother 5 parts, antioxidant 1076 0.2 parts, zinc stearate 0.3 parts, EBS 0.3 parts, methyl silicone oil 0.2 parts.

[0127] A method for preparing a flame-retardant plastic modified material for extrusion molding of automobile bellows, comprising the following preparation steps:

[0128] Step A. by weight, PA6 resin, LLDPE resin, PA12, EPDM-G-MAH, DBDPE, Sb 2 o 3 , black masterbatch, antioxidant, zinc stearate, EBS, and methyl silicone oil were put into a high-speed mixer and stirred for 3 minutes to form mixture Ⅰ;

[0129] Step B. Put the mixture I into a twin-screw extruder, melt and extrude at 250°C, and then cool, air-dry, and pelletize to obtain the flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com