Gel curing solution and preparation method thereof

A solidification liquid and gel technology, which is applied in coalbed methane engineering and petroleum fields, can solve the problems of non-solidification of drilling fluid, failure of cementing interface, and low plugging strength, so as to improve interlayer isolation effect and good water resistance Invasion ability and the effect of preventing oil, gas and water from crossing each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

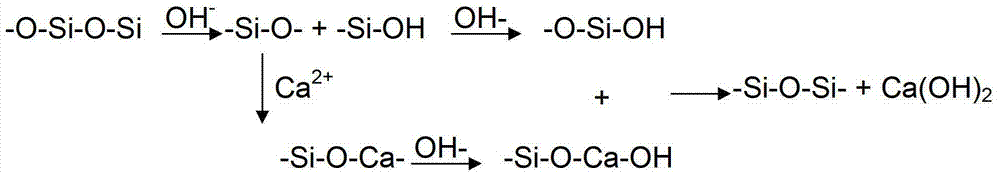

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 6g of activator and 18g of regulator in 600ml of water. After being fully dissolved, slowly add 300g of blast furnace slag under low-speed stirring, and then stir at high speed until the system is uniform, that is, the gel solidified liquid of the present invention is obtained.

[0021] This gel solidified fluid was used as cementing pilot slurry, and it was tested in Well Huadong 6-3X in Fushan Oilfield, Hainan. The main oil and gas intervals in this well are 3786.0m~3966.0m, most of which are measured by CBL / VDL from 3786.0m~3997.5m The sound amplitude of the well section is lower than 10%. The variable density of the sound wave reflects the formation wave clearly. The first interface is well cemented and the second interface is well cemented. The overall evaluation of the cementing quality of this section is good.

Embodiment 2

[0023] Dissolve 12g of activator and 34g of regulator in 600ml of water. After fully dissolving, slowly add 330g of blast furnace slag under low-speed stirring, and then stir at high speed until the system is uniform to obtain the gel solidification solution of the present invention.

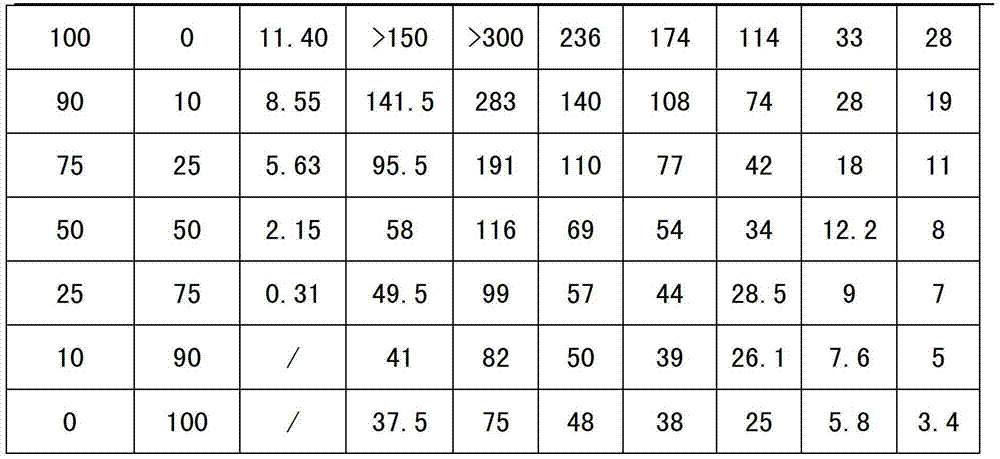

[0024] The gel solidified liquid prepared by the present invention is mixed with mud and cement slurry respectively, and its rheological properties are tested to characterize the compatibility of the gel solidified liquid with mud and cement slurry. The data are as follows:

[0025] Table 1: Compatibility test of gel solidification fluid and mud

[0026]

[0027]

[0028] It can be seen from Table 1 that there is no sudden change in the rheological properties after the gel solidification liquid and mud are mixed in different proportions, and the mixture is homogeneous and stable. It can be seen that the gel-solidified liquid system has good compatibility with the mud, and the system has a ...

Embodiment 3

[0033] Dissolve 6g of activator and 18g of regulator in 600ml of water. After fully dissolving, slowly add 300g of blast furnace slag under low-speed stirring, and then stir at high speed until the system is uniform, that is, the gel solidified liquid of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com