Preparation method of bainite/martensite/austenite composite high-strength steel

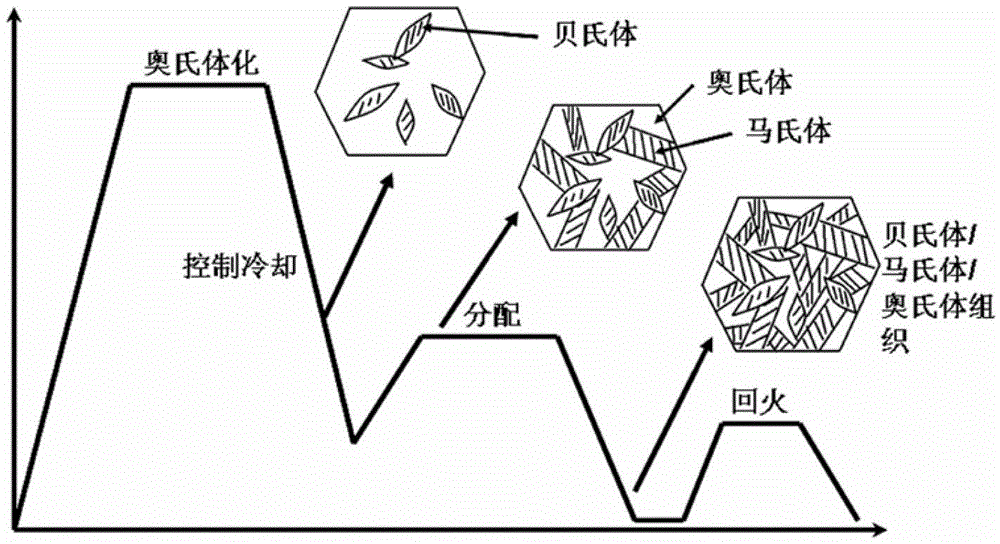

A bainite and martensite technology, which is applied in the field of preparation of bainite/martensite/austenite multiphase high-strength steel, can solve the problems of easy cracking of components, short distribution time, and difficulty in industrialized production. Good combination of strong plasticity and toughness, good combination of strong plasticity and extended distribution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

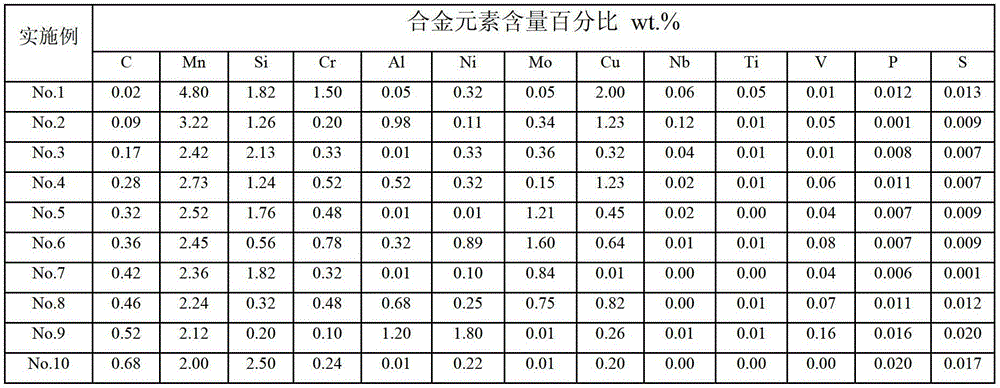

Embodiment 1

[0025] (1) After being smelted by the conventional steelmaking process, it is rolled into a medium-thick steel plate with a thickness of 30mm;

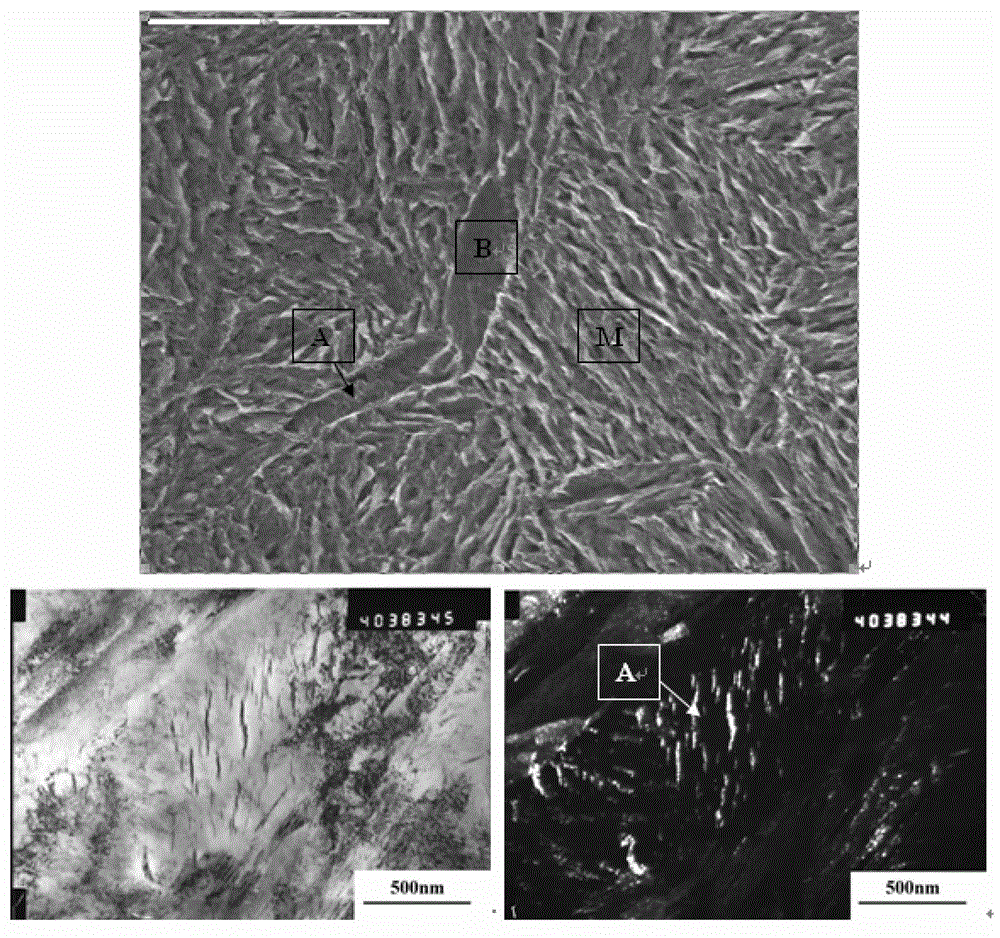

[0026] (2) Heat the above-mentioned steel to 1050°C for 1 hour for austenitization, then use water cooling, cool to 360°C, and immediately reheat to 500°C for distribution treatment. The distribution time is 120 minutes, and after distribution treatment, air cool to room temperature ;

[0027] (3) The above-mentioned steel material is kept at 100° C. for 2 hours for low-temperature tempering treatment.

Embodiment 2

[0029] (1) After being smelted by the conventional steelmaking process, it is rolled into a medium-thick plate with a thickness of 80mm;

[0030] (2) Heat the above steel to 1050°C for 2 hours for austenitization, then use water cooling, cool to 320°C, and immediately reheat to 450°C for distribution treatment. The distribution time is 180 minutes, and after distribution treatment, air cool to room temperature ;

[0031] (3) The above-mentioned steel material is kept at 280° C. for 3 hours for low-temperature tempering treatment.

Embodiment 3

[0033] (1) After smelting by conventional steelmaking process, it is rolled into a steel bar with a diameter of 32mm;

[0034] (2) Heat the above-mentioned steel to 920°C for 1 hour for austenitization, then perform salt bath treatment, cool to 320°C, and immediately reheat to 280°C for distribution treatment. The distribution time is 40 minutes, and air cooling after distribution treatment to room temperature;

[0035] (3) The above-mentioned steel material is kept at 250° C. for 5 hours for low-temperature tempering treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com