Cotton/viscose glue and acetate fiber mixed fabric dyeing and finishing process

A technology of interweaving cloth and viscose, applied in fiber treatment, plant fiber, biochemical fiber treatment and other directions, can solve the problems of stiff hand, unsatisfactory hand feel and color brightness of dyed fabrics, restricting the production process of fabrics, etc., and meet the equipment requirements. Simple, craft and color control for easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

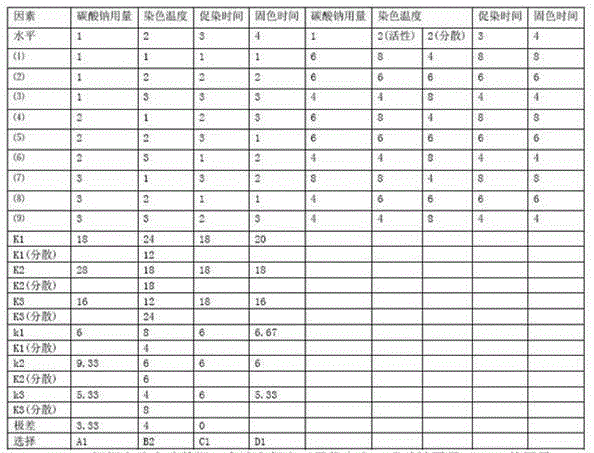

Examples

Embodiment 1

[0152] In this embodiment, the dyeing and finishing process of the cotton / viscose and acetate interwoven cloth is carried out in the jigger, and the process includes: pre-treatment of the cloth, dyeing and post-treatment of the cloth, the pre-treatment of the cloth includes: burning Wool, desizing and bleaching; the post-processing of the fabric includes: soft setting, calendering and shrinkage.

[0153] In the desizing treatment, the unwinding speed of the jigger is set at 60 m / min, and the bath ratio is 1:3; the treatment liquid of the desizing treatment includes:

[0154] Enzyme desizing agent 6 g / L;

[0155] Complexing agent 3 g / L;

[0156] Scouring agent 6 g / L;

[0157] Processing process: heat up to 80°C at a heating rate of 1.5~3°C / min, repeat 3 times, and the processing time is 45 minutes; then continue to heat up to 100°C, repeat 6 times, and the processing time is 90 minutes; then discharge the desizing liquid, The cloth is washed with water, the water temperature...

Embodiment 2

[0191] In this embodiment, the dyeing and finishing process of the cotton / viscose and acetate interwoven cloth is carried out in the jigger, and the process includes: pre-treatment of the cloth, dyeing and post-treatment of the cloth, the pre-treatment of the cloth includes: burning Wool, desizing and bleaching; the post-processing of the fabric includes: soft setting, calendering and shrinkage.

[0192] In the desizing treatment, the unwinding speed of the dyeing jigger was set at 60 m / min, and the liquor ratio was 1:4; the treatment liquid and treatment process of the desizing treatment were the same as in Example 1.

[0193] In the bleaching treatment, the unwinding speed of the dyeing jigger is 60 m / min, and the liquor ratio is 1:4; the treatment solution and treatment process of the bleaching treatment are the same as in Example 1.

[0194] In the dyeing process, the dyeing step specifically includes:

[0195] (1) Prepare the dye solution according to the following formu...

Embodiment 3

[0204] In this embodiment, the dyeing and finishing process of the cotton / viscose and acetate interwoven cloth is carried out in the jigger, and the process includes: pre-treatment of the cloth, dyeing and post-treatment of the cloth, the pre-treatment of the cloth includes: burning Wool, desizing and bleaching; the post-processing of the fabric includes: soft setting, calendering and shrinkage.

[0205] In the desizing treatment, the unwinding speed of the jigger was set at 60 m / min, and the liquor ratio was 1:5; the treatment liquid and treatment process of the desizing treatment were the same as in Example 1.

[0206] In the bleaching treatment, the unwinding speed of the jigger is 60 m / min, and the bath ratio is 1:3; the treatment liquid and the treatment process of the bleaching treatment are the same as in Example 1.

[0207] In the dyeing process, the dyeing step specifically includes:

[0208] (1) Prepare the dye solution according to the following formula:

[0209] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com