Cap beam efficient, convenient and quick to construct and construction method thereof

A construction method, cap beam technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction quality control of high supports, a large amount of manpower and material resources, and high construction costs, so as to save the construction time , environmental protection science, and the effect of providing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

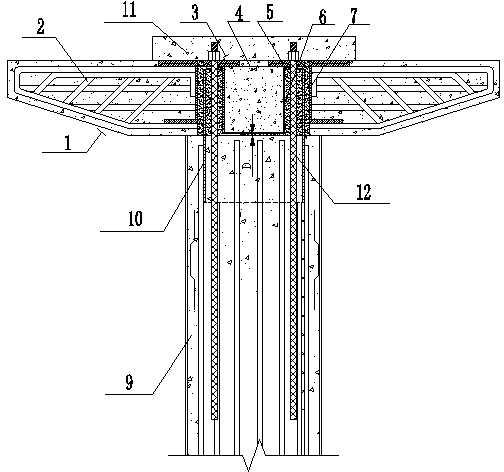

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

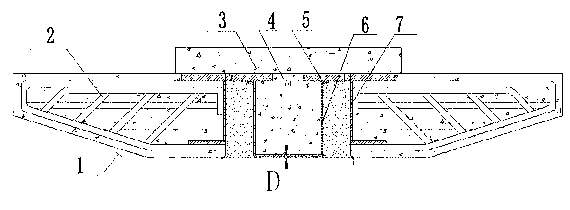

[0029] figure 1 As shown, it is a schematic diagram of the front structure of the cap beam 1, which includes a cap beam steel skeleton 2 and a cap beam embedded part 3. In the middle of the cap beam steel skeleton 2, a cap beam embedded part 3 is provided; 2 is filled with poured concrete.

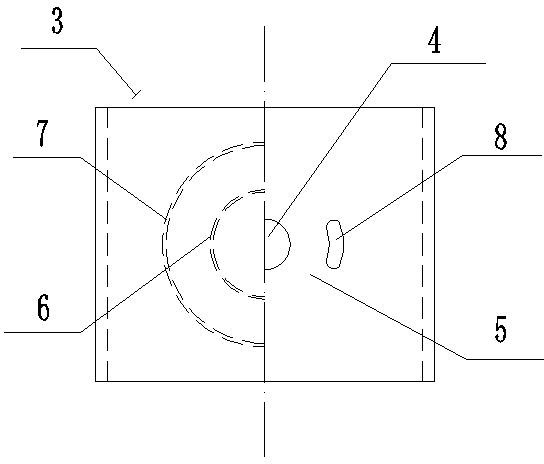

[0030] combine figure 2 As shown, it is a structural schematic diagram of the top view of the embedded part 3 of the cap beam, and it can be seen by cutting half of the top plate 5: the embedded part 3 of the cap beam includes the outer ring steel pipe 7, the inner ring steel pipe 6 and the top plate 5; wherein, the outer ring steel pipe 7 is arranged on the outside of the inner ring steel pipe 6, and the tops of the outer ring steel pipe 7 and the inner ring steel pipe 6 are fixedly connected with the bottom surface of the top plate 5; the bottom surface of the inner ring steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com