A method for collaborative resource treatment of garbage fly ash and metallurgical dust

A garbage fly ash and recycling technology, applied in the field of solid dust and garbage fly ash comprehensive treatment, can solve the problems of corrosive equipment, large investment, high energy consumption, etc., and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

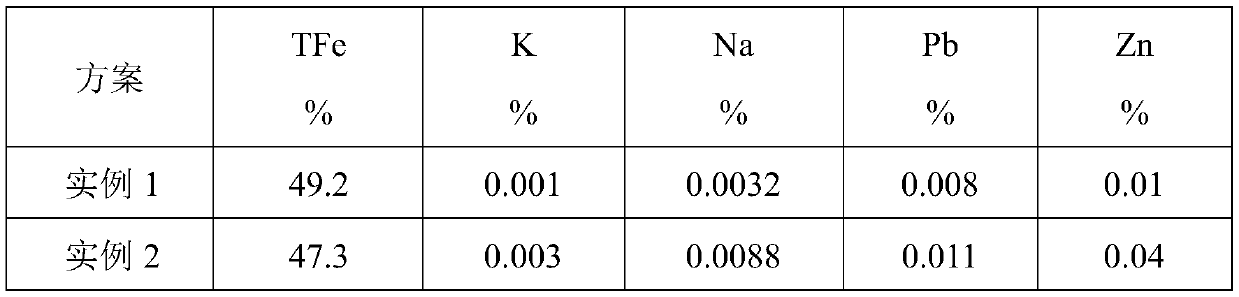

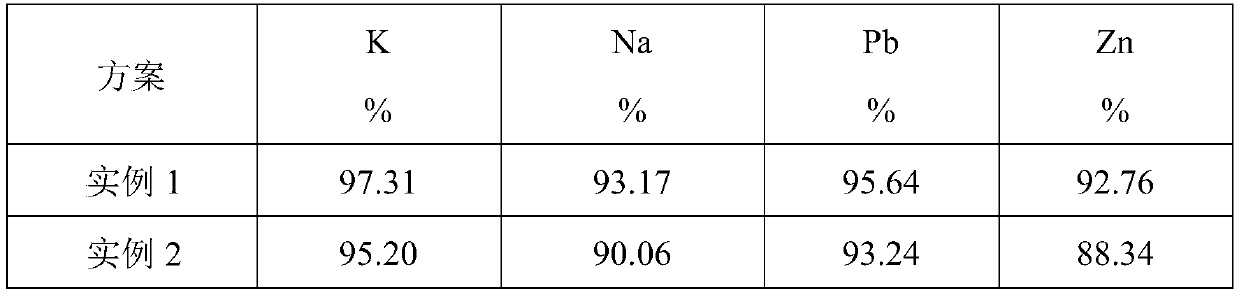

Embodiment 1

[0027] The garbage fly ash, metallurgical dust, and solid fuel are prepared to make iron grade 47%, is 0.3, is 0.6, n (Cl) / n (2Pb+2Zn+K+Na) 0.85, the total carbon content is 10% of the mixture, made into pellets with a particle size of 12mm, and dried at 80°C for 60 minutes, and then the dried pellets were roasted at 1300°C for 10 minutes, and dusted with a bag filter The valuable metal dust in the flue gas was collected, and the composition of the final roasted product is shown in Table 1. The high temperature treatment process effectively removes K, Na, Pb, Zn, the contents are all lower than 0.05%, the dioxin in the fly ash is effectively degraded, the final iron grade of the agglomerate is 49.2%, and the drum strength is 79%, which can be used as a blast furnace Furnace charge. The removal rates of K, Na, Pb, and Zn in the roasting process are shown in Table 2, and the removal rates are all above 90%, so they can be enriched in flue gas and dust for recycling.

Embodiment 2

[0029] The waste fly ash, metallurgical dust, and solid fuel are prepared into 45% iron grade, is 0.25, is 0.5, n (Cl) / n (2Pb+2Zn+K+Na)1.0, the total carbon content of the mixture is 5%, made into pellets with a particle size of 10mm, and dried at 150°C for 20min, and then the dried pellets were roasted at 1150°C for 60min, and dusted with a bag filter. The valuable metal dust in the flue gas was collected, and the composition of the final roasted product is shown in Table 1. The high-temperature treatment process can effectively remove K, Na, Pb, and Zn, and ensure that the content in the agglomerate is less than 0.05%. The final iron grade of the agglomerate is 47.3%, and the drum strength is 75%. It can be used as a blast furnace ironmaking charge. The removal rates of K, Na, Pb, and Zn during the roasting process are shown in Table 2. The removal rates of K, Na, and Pb are all above 90%, and the removal rate of Zn also reaches 88.34%, so that it can be enriched in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com