Composite stirrup

A technology of composite materials and stirrups, which is applied in the field of composite material stirrups, can solve the problems of non-standard use of sea sand mixing concrete, failure of components, hidden safety hazards, etc., to achieve increased rigidity, rapid forming, and improved overall mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

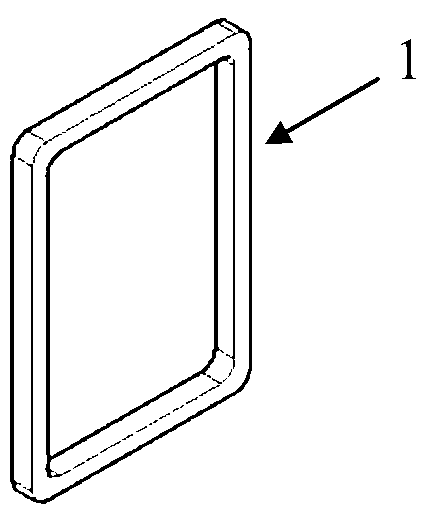

[0026] Such as Figure 6 As shown, a composite material stirrup is an ordinary rectangular stirrup 1, which is used in a precast concrete beam, and the longitudinal reinforcement at the bottom of the beam and the vertical reinforcement at the top of the beam are both composite material reinforcement. When in use, the composite material bars are inserted into the rectangular stirrups 1 and bound with thin iron wires to form a reinforcement cage. The ordinary rectangular stirrup 1 is prefabricated in a factory and manufactured by manual winding, that is, the resin-impregnated composite fiber bundle is wound on a pre-made mold, and the mold can be released after the resin is cured.

Embodiment 2

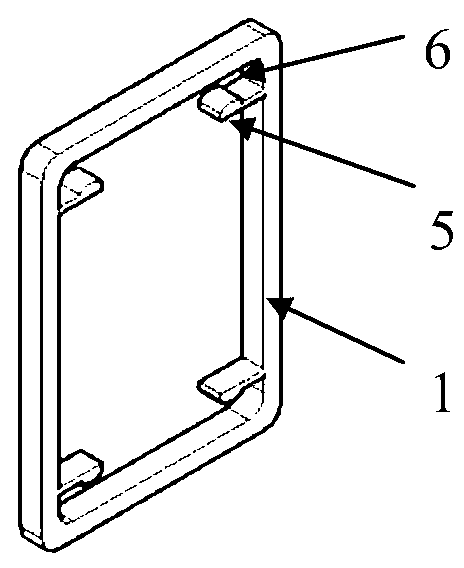

[0028] Such as Figure 7 As shown, a composite material stirrup is a rectangular stirrup 1 with a composite material bracket 5, which is used in a concrete beam. The longitudinal reinforcement at the bottom of the beam and the vertical reinforcement at the top are both composite material reinforcement, and the concrete is made of sea sand Mixed concrete. When in use, pass the composite material longitudinal reinforcement and vertical reinforcement through the rectangular stirrup 1, and press them into the clamping groove to be fixed. The rectangular stirrup 1 with the composite material bracket 5 is prefabricated in the factory. Firstly, a composite material cavity profile with the same cross-sectional shape as the rectangular stirrup 1 is produced by pultrusion process, and then the corresponding width is cut according to the designed size to form the rectangular stirrup. Rectangular stirrup 1 with bracket 5 of composite material.

Embodiment 3

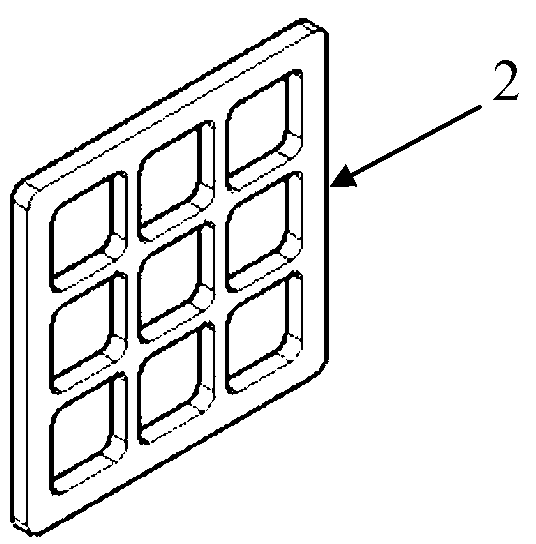

[0030] Such as Figure 8 As shown, a composite material stirrup is a rectangular composite stirrup 2, which is used in a concrete column. 2. Fix it with the longitudinal reinforcement to form a reinforcement cage (the thin iron wire at the binding place is omitted in the figure). The rectangular composite stirrup 2 is prefabricated in a factory. Firstly, a multi-cavity hollow tube of composite material with the same cross-sectional shape as the stirrup is produced by pultrusion process, and then the corresponding width is cut according to the designed size to form the rectangular composite stirrup 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com