Carbon dioxide hydrate slurry cold storing and releasing central air conditioning unit

A technology of carbon dioxide and hydrate slurry, which is applied in air-conditioning systems, space heating and ventilation, household heating, etc., can solve the problems of lack of cold storage function of cooling devices, small size of hydrate reactors, and inability to provide driving energy. Achieve the effect of saving electricity expenses, reducing energy consumption, and even and more thorough hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following embodiments describe the present invention in detail in conjunction with the accompanying drawings.

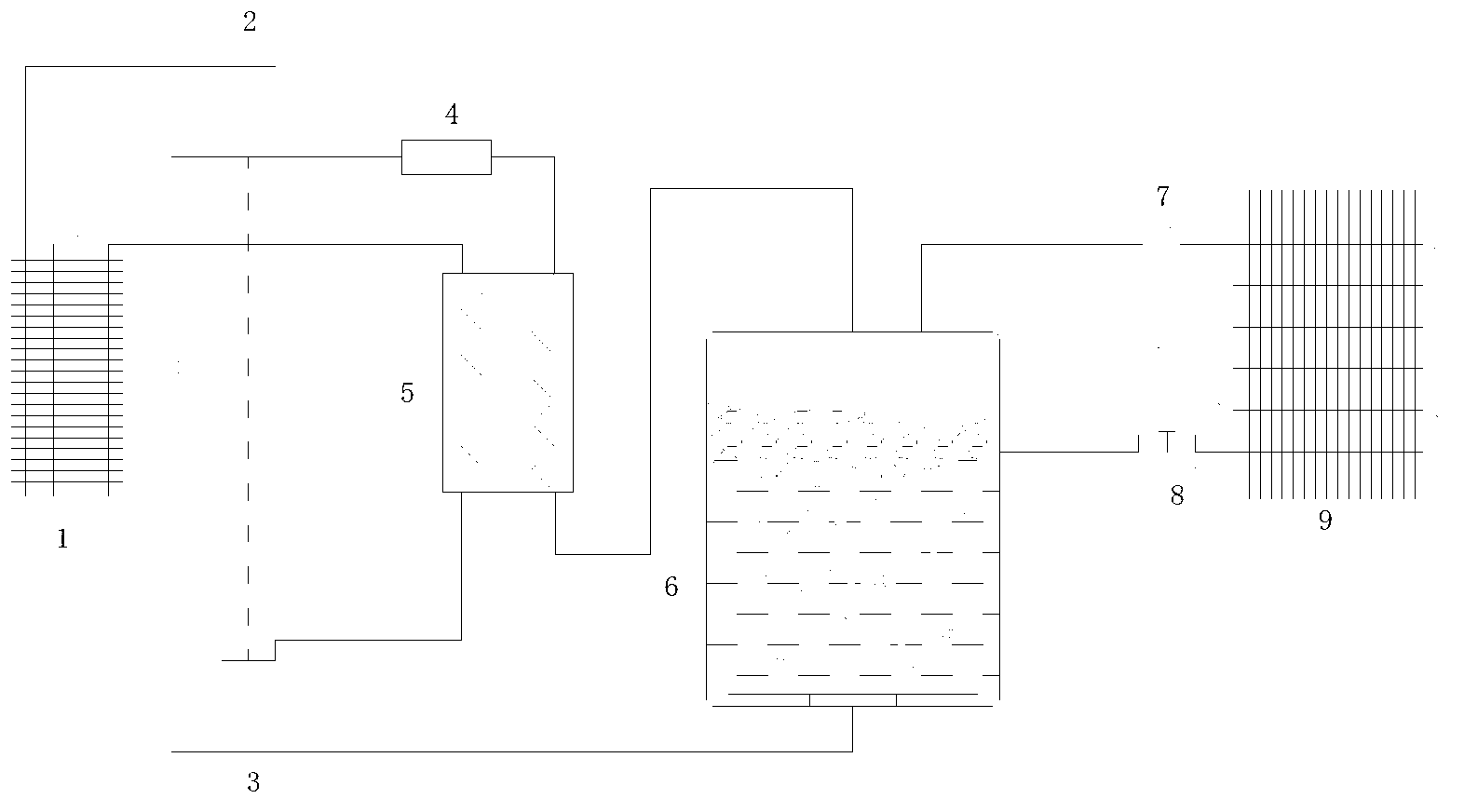

[0018] figure 1 Is a kind of CO of the present invention 2 Schematic diagram of the structure of the central air-conditioning device for cold storage and release of hydrate slurry.

[0019] Such as figure 1 As shown, this example involves CO 2 The central air-conditioning device for cold storage and release of hydrate slurry includes the following parts: compressor 2, cooler 1, regenerator 5, expander 3, hydration reactor 6, air cooler 9, control valve 8 and circulation pump 7. The exhaust port of the compressor 2 is connected with the inlet of the cooler, the outlet of the cooler is connected with the expander, and the outlet of the expander is connected with the diffuser orifice plate at the bottom of the hydration reactor, wherein the expander 3 and the compressor 2 pass through a coupling Linkage, CO 2 When the gas expands, it drives the coupling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com