Micro-positive pressure combustion combined cooling energy-saving boiler

A micro-positive pressure, boiler technology, applied in the field of oil-fired boilers, can solve the problems of burnout or deformation of the rear wall, increased power consumption, no energy saving device, etc. The effect of reducing operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

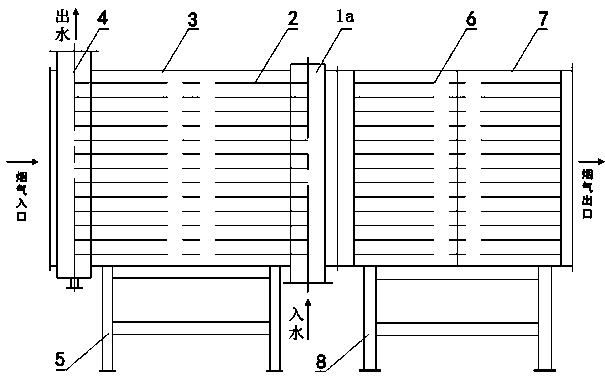

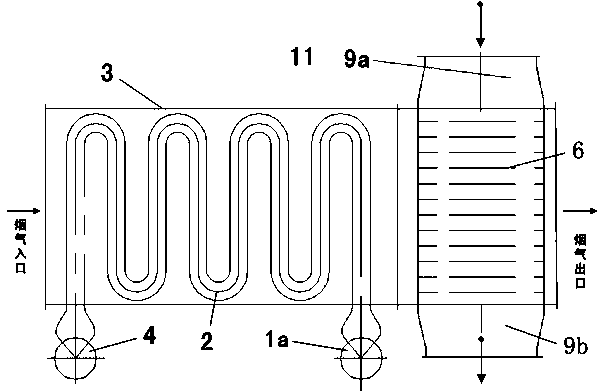

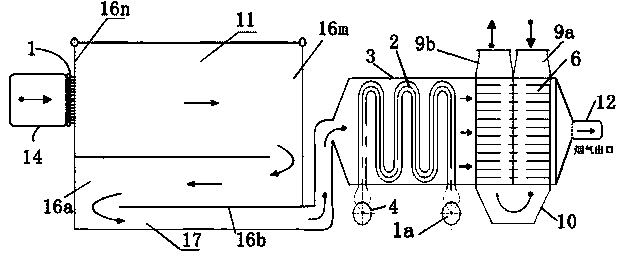

[0022] Such as figure 1 and figure 2 and image 3 , the present invention includes a boiler body and a combined cooling system. The boiler body is provided with an annular header 1, a blower 14 and a multi-return flue gas passage 17, and each return of the flue gas passage 17 is isolated by membrane water-cooled walls 16a, 16b. The combined cooling system is formed by connecting a water cooler and an air cooler. The water cooler includes a serpentine tube group 2 bent back to a plurality of single tubes. The air cooler includes a plurality of linear smoke tubes 6 and is equipped with a smoke The air passages 9a, 9b perpendicular to or intersecting the direction of the pipe 6, the tail of the smoke pipe 6 is provided with an induced draft fan 12;

[0023] It should be pointed out that the cooling system in this embodiment is formed by connecting a pressurized water cooler and a non-pressurized air cooler, and the air blower 14 is integrated with the burner.

[0024] The pre...

Embodiment approach 2

[0035] Such as Figure 4 , the air channel 9a is linear, and the rest are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com