Attemperator for ceramic roller kiln

A heat preservation device and ceramic roller technology, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of reducing solid heat conduction rate, slender heat conduction path, and less solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

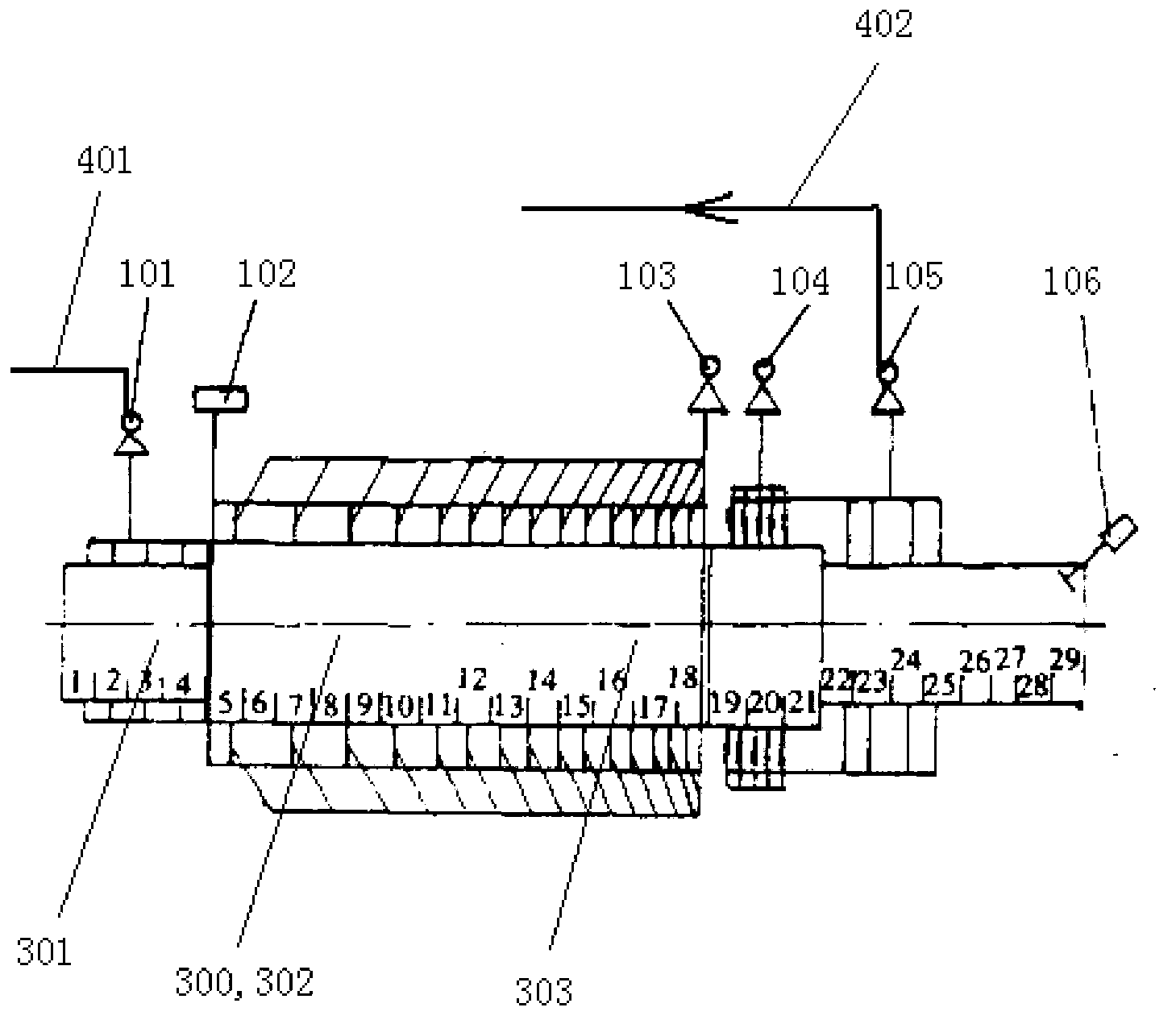

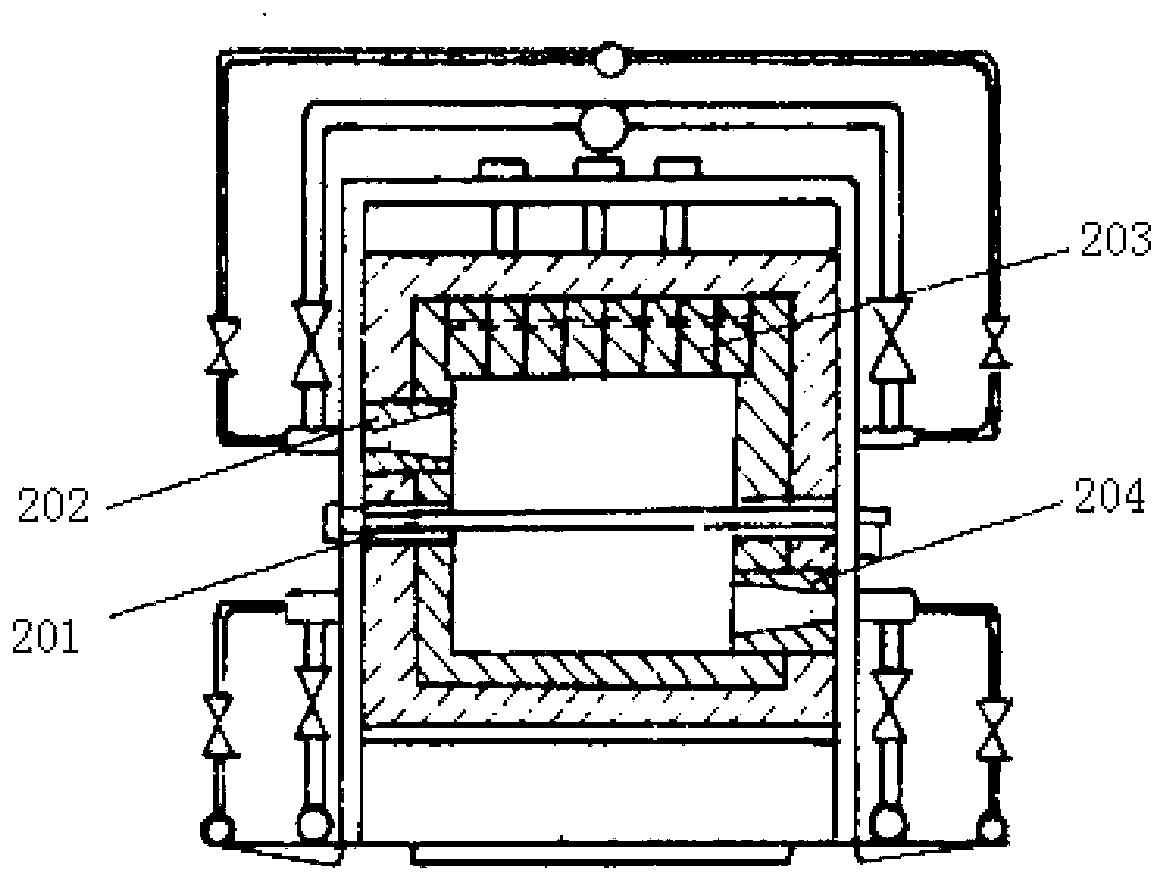

[0054] See figure 1 , 3 And 6, the thermal insulation device of the ceramic roller kiln in this embodiment is the thermal insulation device of the gas-fired open flame roller kiln, including kiln body thermal insulation parts and pipeline thermal insulation parts.

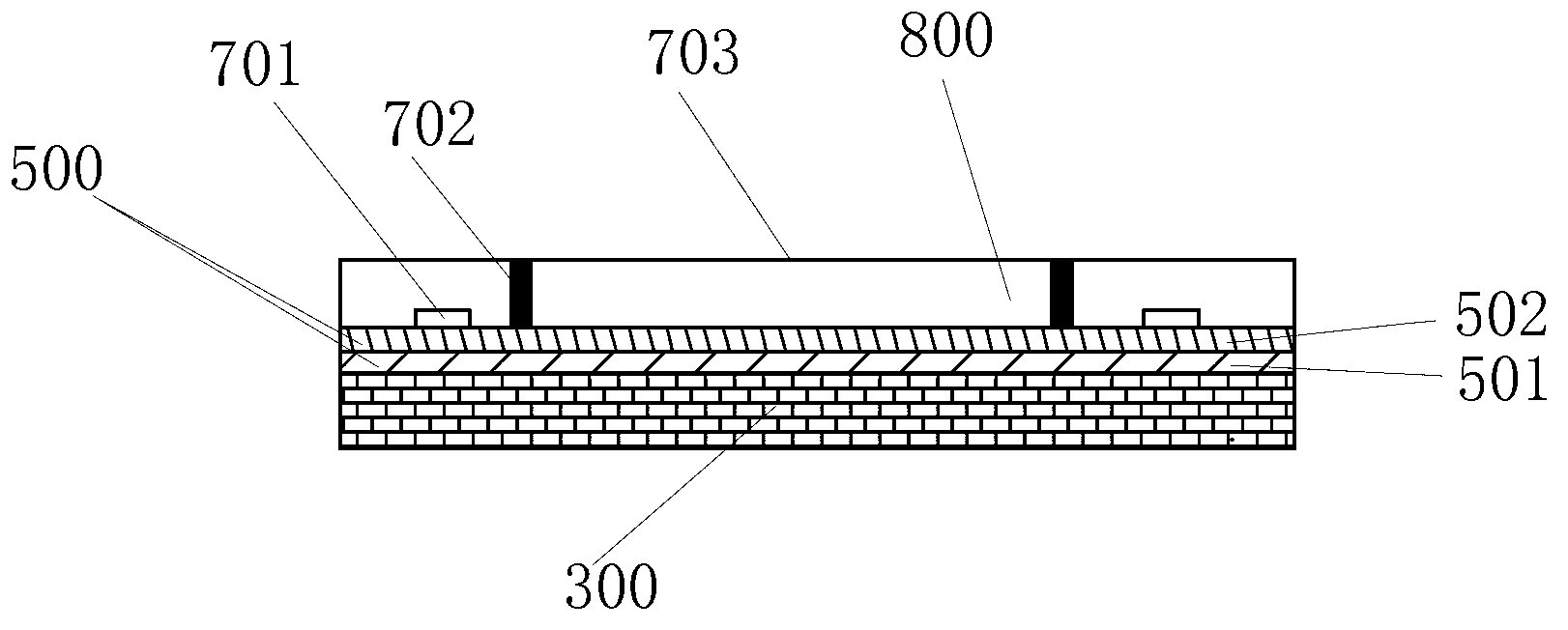

[0055] See image 3 , The kiln body heat preservation parts include a thermal insulation composite layer 500, a fixing part 701, a support bar 702, and an iron sheet 703. The thermal insulation composite layer 500 is composed of an aluminum silicate fiber blanket layer 501 and a first airgel thermal insulation blanket layer 502 .

[0056] The aluminum silicate fiber blanket layer 501 and the first airgel thermal insulation blanket layer 502 are laid sequentially from the inside to the outside to cover all the outer surfaces of the ceramic roller kiln kiln body where the thermal insulation layer 300 is installed, and the fixing member 701 is set Outside the first airgel thermal insulation blanket layer 502, the t...

Embodiment 2)

[0073] See Figure 4 and Figure 5 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the kiln body insulation part of this embodiment also includes an insulation composite layer 600 . The thermal insulation composite layer 600 is divided into single thermal insulation composite layer 600a, double thermal insulation composite layer 600b and triple thermal insulation composite layer according to the number of glass fiber felt layers and airgel thermal insulation blanket layers included. The single thermal insulation composite layer 600a has only one composite layer, that is, the first glass fiber felt layer 601 and the second airgel thermal insulation blanket layer 602 are sequentially arranged from inside to outside. The double thermal insulation composite layer 600b has 2 composite layers, that is, the first glass fiber felt layer 601, the second airgel thermal insulation blanket layer 602, the second glass fiber felt layer 603 and the...

Embodiment 3)

[0082] The rest of this embodiment is the same as that of Embodiment 1, except that: the thermal insulation device of the ceramic roller kiln of this embodiment also includes a roller gap thermal insulation member.

[0083] The roller gap insulation part is made of hard airgel heat insulating material, and the shape of the roller gap insulation part matches the shape of the gap between the rollers, and is closely attached to the rollers. The rigid airgel thermal insulation material used in this embodiment is RunAG1000-10 type rigid airgel manufactured by Changzhou Xuntian Energy Saving Technology Co., Ltd.

[0084] The gap between the rollers in the prior art has serious heat dissipation, and is generally blocked with aluminum silicate loose cotton, and the aluminum silicate loose cotton is often burned and needs to be replaced once a month. And the roller gap insulation parts can keep using for about 1 year without failure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com