Method of manufacturing power transistor device

A technology of power transistor and manufacturing method, which is applied in the field of manufacturing power transistor components, can solve problems such as uneven distribution of hole concentration and electron concentration, achieve the effect of reducing surface doping concentration and improving withstand voltage capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

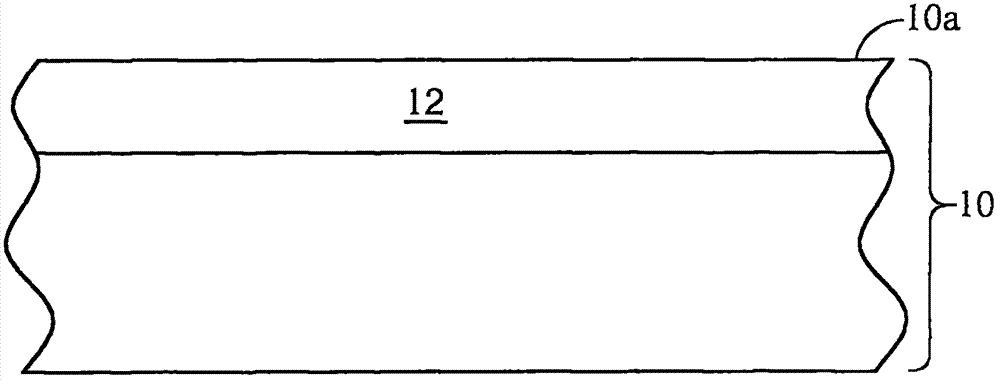

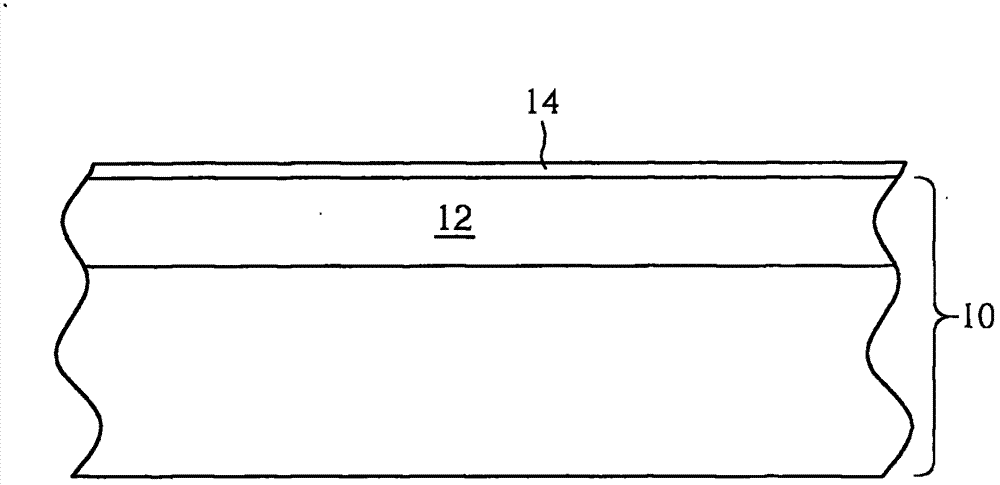

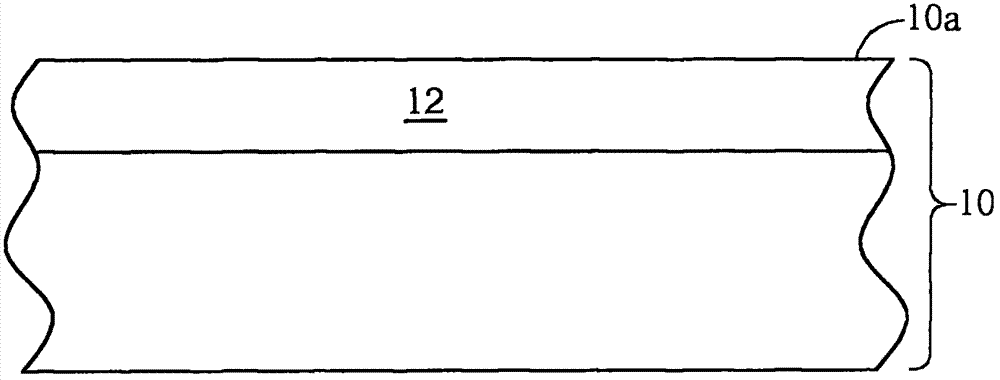

[0029] Please refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a schematic diagram of a method for reducing the surface doping concentration of a diffused doping region according to a preferred embodiment of the present invention. Such as figure 1 As shown, first, a semiconductor substrate 10, such as a silicon wafer, is provided. The semiconductor substrate 10 has a diffusion doping region 12 disposed therein, and the diffusion doping region 12 is in contact with an upper surface 10 a of the semiconductor substrate 10 . Moreover, the doping concentration of the diffused doping region 12 adjacent to the upper surface 10a is greater than the doping concentration of the diffused doping region 12 away from the upper surface 10a. Such as figure 2 As shown, subsequently, a thermal oxidation process is performed to form an oxide layer 14 on the upper surface 10 a of the semiconductor substrate 10 . Moreover, a part of the diffusion doped region 12 in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com