Electric machine used as motor in motor car

A technology for driving shafts and connecting components, which is applied in the direction of electromechanical devices, machines/engines, engine starting, etc., and can solve problems such as failure and drive shaft cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

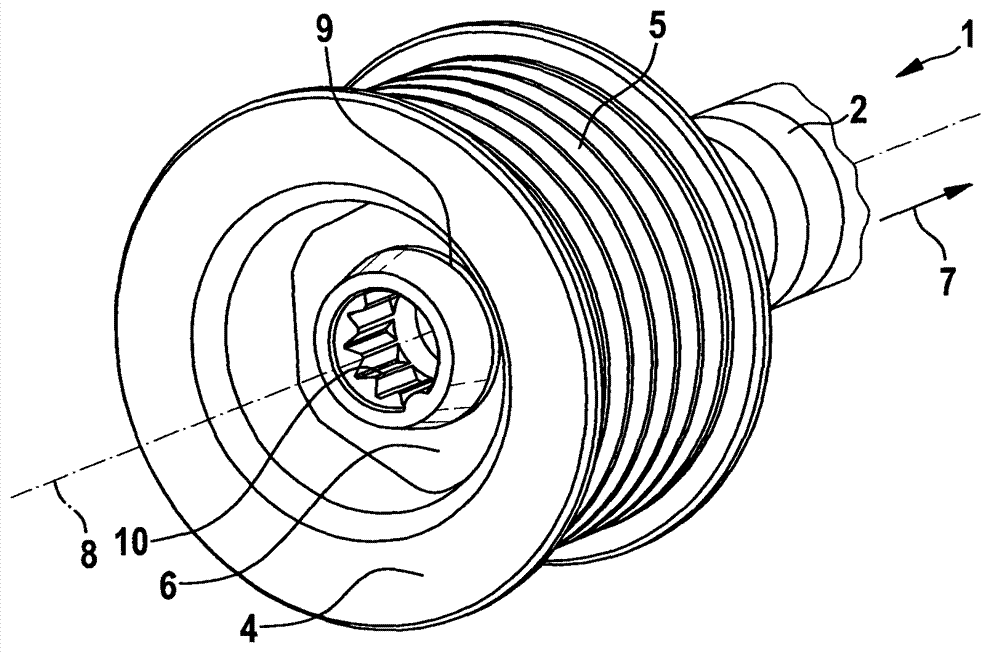

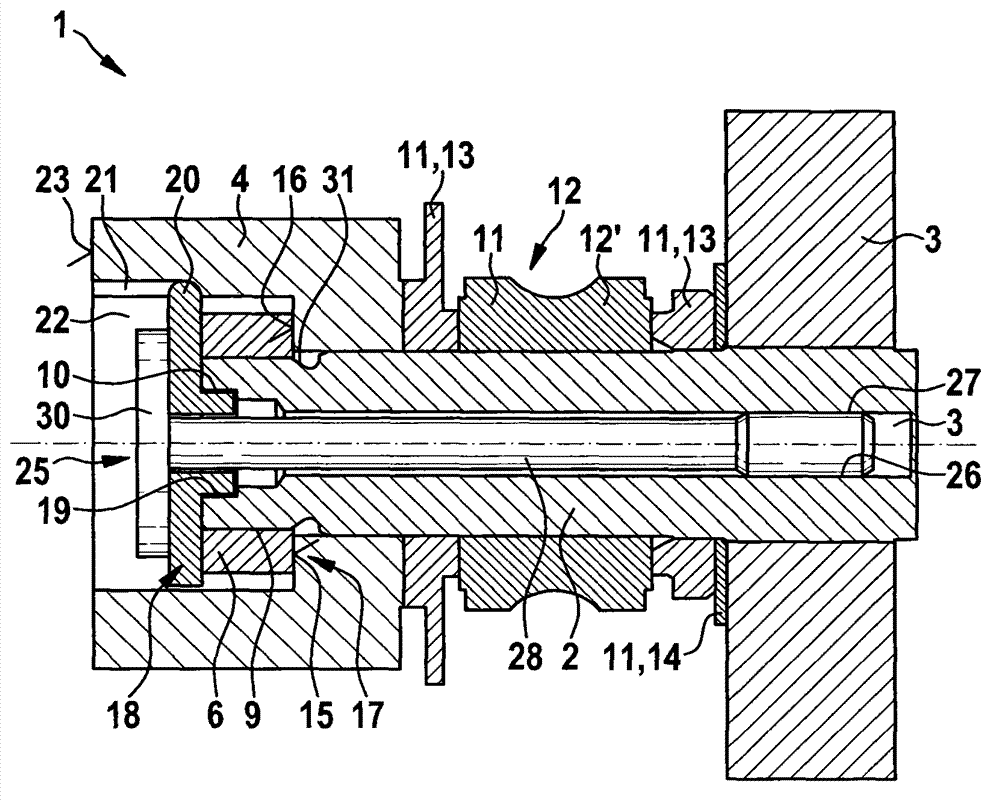

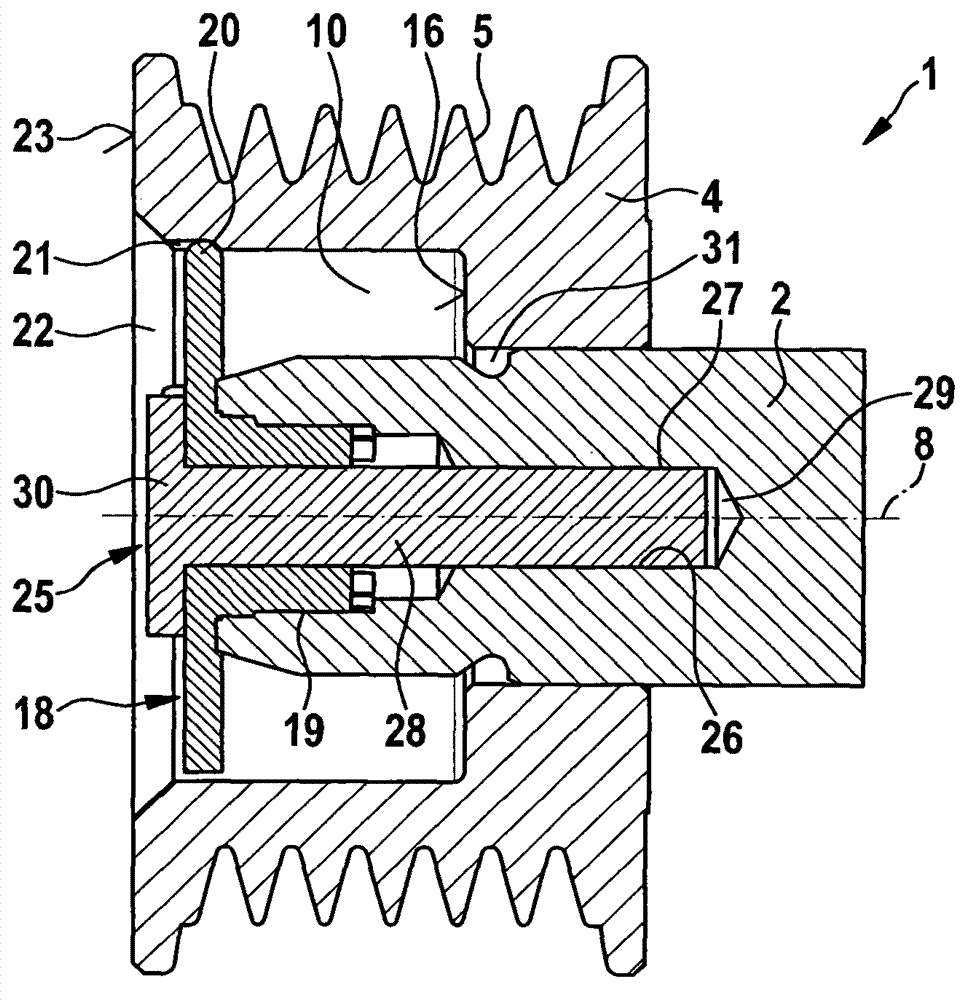

[0027] figure 1 A partial view of a conventional electric machine 1 is shown. The electric machine 1 can be used, for example, as a motor, a generator or also as a motor-generator. It has a drive shaft 2 through which the motor can give or receive torque. A rotor 3 (not shown here) and a coupling element 4 preferably spaced from the rotor 3 in the axial direction are arranged on the drive shaft 2 . The coupling element 4 serves, for example, as a pulley, ie has a revolving surface 5 for bending a flexible winding means, such as a belt. The coupling element 4 is fastened to the drive shaft 2 by means of a fastening element 6 and is pressed by the fastening element in the direction of the rotor 3 , ie in the direction of the arrow 7 . The arrow 7 is here parallel to the longitudinal axis 8 or the axis of rotation of the drive shaft 2 .

[0028] The securing element 6 is in the form of a nut, which is screwed onto the outer shaft thread 9 of the drive shaft 2 , which is only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com