Evaporator and method for preventing heating chamber from being blocked during evaporation and concentration of sodium permanganate

A sodium permanganate, evaporation and concentration technology, applied in the direction of evaporator accessories, etc., can solve problems such as labor-intensive, energy-consuming, and evaporator wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

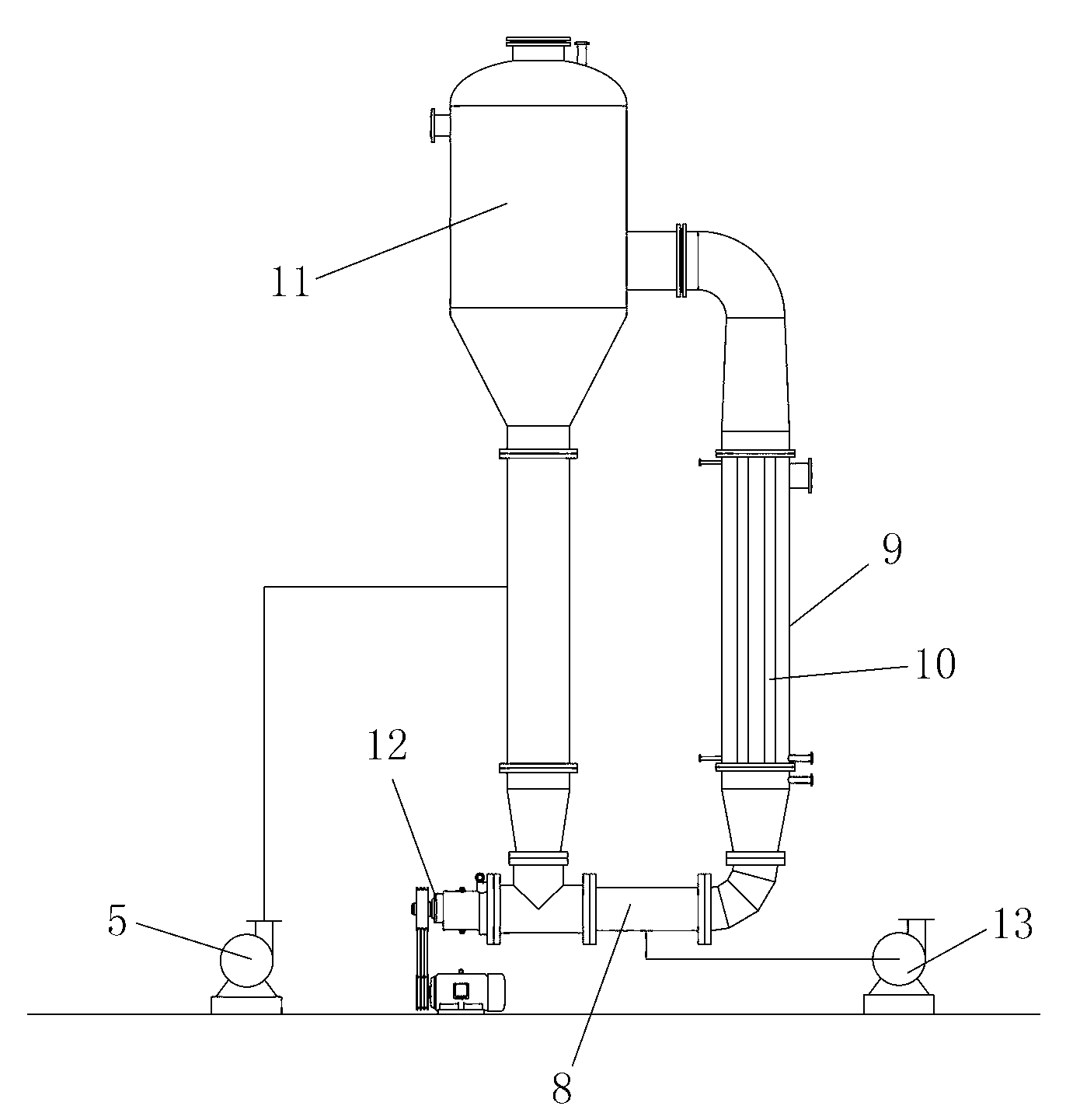

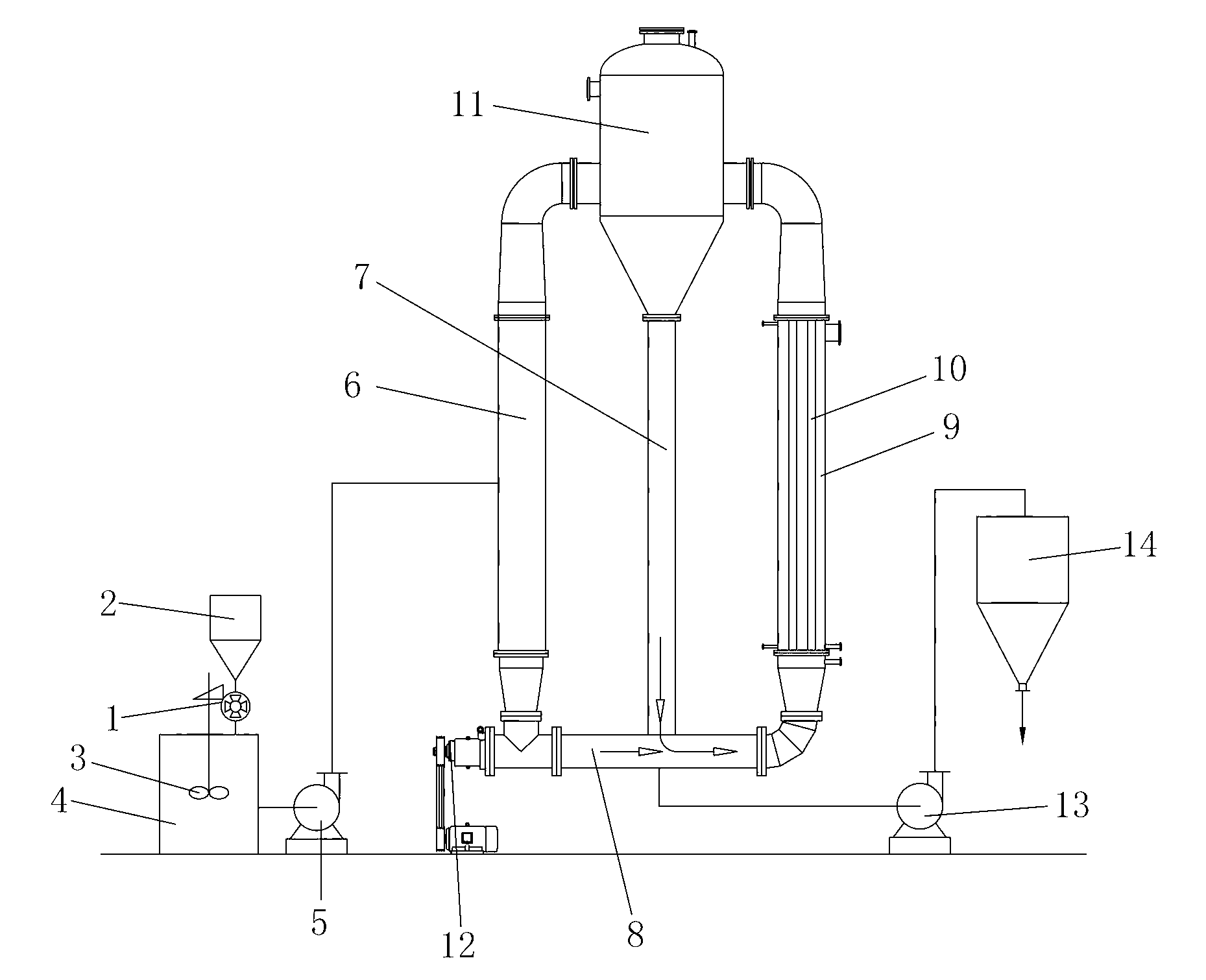

[0021] The structure of the evaporator of this embodiment is as above. This embodiment is used for the method for preventing the heating chamber from clogging when sodium permanganate is evaporated and concentrated. The evaporator of the present invention is applied: the sodium permanganate feed liquid to be evaporated is put into the mixing tank 4, and then passed through the sand feeding device 1 The quartz sand storage tank 2 puts the quartz sand into the mixing tank 4, and the quartz sand and the sodium permanganate feed liquid to be evaporated are stirred and mixed by the agitator 3 to obtain a mixture, and finally the mixture is conventionally concentrated. The particle fineness of the quartz sand is 0.1 mm, and the weight ratio of the quartz sand to the sodium permanganate feed solution to be evaporated is 1:100.

[0022] The advantage of this embodiment is: under the conditions of particle fineness and weight ratio, the same sodium permanganate feed liquid is conventio...

Embodiment 2

[0025] This embodiment is used for the method for preventing the heating chamber from clogging when sodium permanganate is evaporated and concentrated. The evaporator of the present invention is applied: the sodium permanganate feed liquid to be evaporated is put into the mixing tank 4, and then passed through the sand feeding device 1 The quartz sand storage tank 2 puts the quartz sand into the mixing tank 4, and stirs and mixes the quartz sand with the highly evaporated sodium permanganate feed liquid through the agitator 3 to obtain a mixture, and finally the mixture is conventionally concentrated. The particle fineness of the quartz sand is 0.15 mm, and the weight ratio of the quartz sand to the sodium permanganate feed liquid to be evaporated is 1:100.

[0026]The advantage of this embodiment is: under the condition of particle fineness and weight ratio, the same sodium permanganate feed liquid is conventionally concentrated and heated, and the heating pipe blockage ...

Embodiment 3

[0030] This embodiment is used for the method for preventing the heating chamber from clogging when sodium permanganate is evaporated and concentrated. The evaporator of the present invention is applied: the sodium permanganate feed liquid to be evaporated is put into the mixing tank 4, and then passed through the sand feeding device 1 The quartz sand storage tank 2 puts the quartz sand into the mixing tank 4, and stirs and mixes the quartz sand with the highly evaporated sodium permanganate feed liquid through the agitator 3 to obtain a mixture, and finally the mixture is conventionally concentrated. The particle fineness of the quartz sand is 0.18 mm, and the weight ratio of the quartz sand to the sodium permanganate feed solution to be evaporated is 1:100.

[0031] The advantage of this embodiment is: under the condition of particle fineness and weight ratio, the same sodium permanganate feed liquid is conventionally concentrated and heated, and the heating tube in the chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com